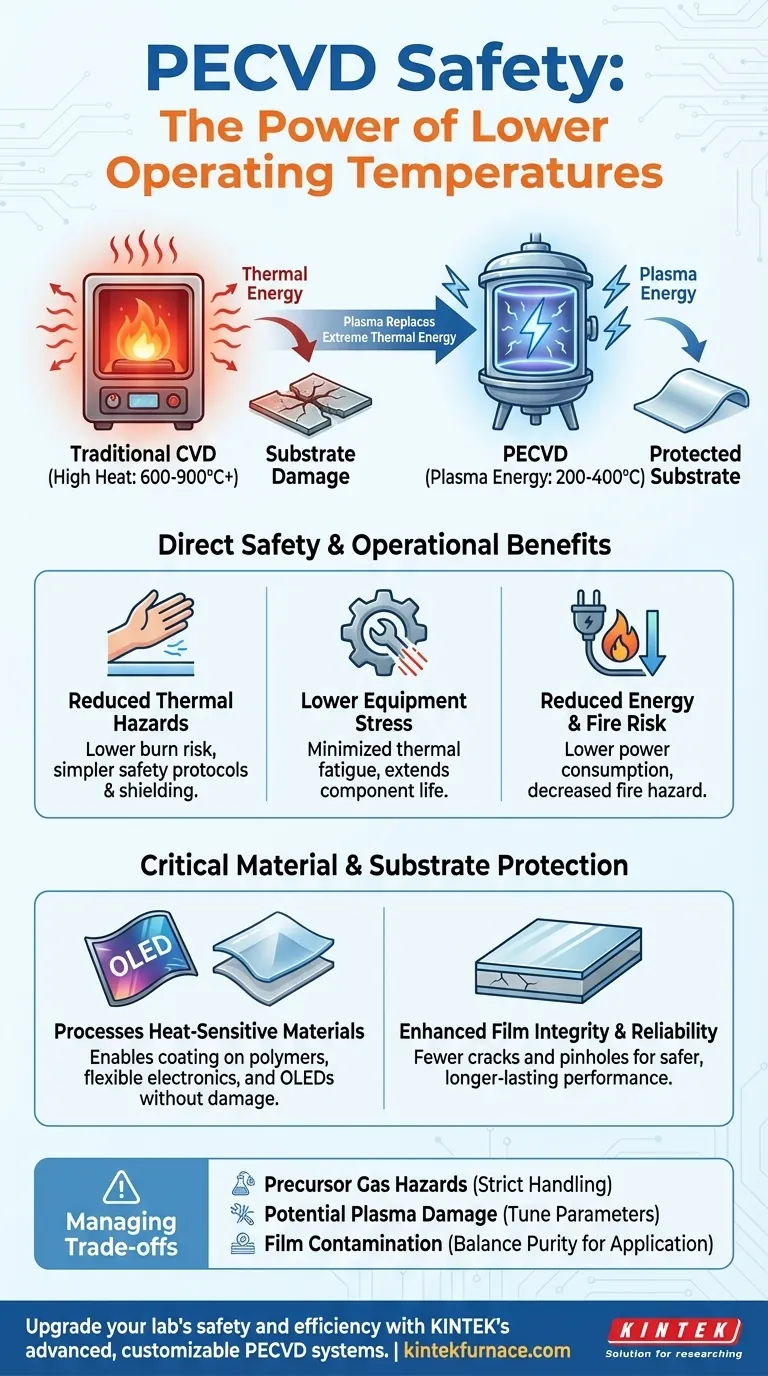

From a safety perspective, the most significant advantage of Plasma-Enhanced Chemical Vapor Deposition (PECVD) is its dramatically lower operating temperature. Unlike conventional methods that rely on extreme heat, PECVD uses plasma to drive chemical reactions, which fundamentally reduces thermal hazards, lessens stress on equipment, and allows for the processing of heat-sensitive materials.

PECVD's use of plasma rather than high heat to deposit thin films is the core of its safety benefits. This shift not only protects personnel and hardware from severe thermal risks but also preserves the integrity of materials that would be destroyed by high-temperature alternatives.

The Principle: Replacing Thermal Energy with Plasma

To grasp the safety implications, you must first understand the fundamental difference between PECVD and conventional Chemical Vapor Deposition (CVD).

How High-Temperature CVD Works

Traditional methods, such as Low-Pressure CVD (LPCVD), require extreme temperatures, often in the range of 600°C to over 900°C. This intense heat provides the necessary thermal energy to break down precursor gases and initiate the chemical reactions that form a film on the substrate.

The PECVD Alternative: Energy from Plasma

PECVD achieves the same outcome at much lower temperatures, typically between 200°C and 400°C. It does this by introducing energy in a different form: an electric field creates a plasma, an ionized gas containing high-energy electrons.

These electrons collide with the precursor gas molecules, breaking them into reactive species without needing high heat. This plasma-driven process is the key to all subsequent safety and material benefits.

Direct Safety and Operational Benefits

The lower operating temperature translates directly into a safer and more manageable operational environment.

Reduced Thermal Hazards

Operating at 300°C instead of 800°C drastically reduces the risk of severe burns to personnel. It also lessens the need for extensive thermal shielding and complex, high-temperature-rated safety interlocks around the processing equipment.

Lower Thermal Stress on Equipment

Extreme heat cycles cause materials to expand and contract, placing significant stress on reactor chambers, seals, and heating elements. This leads to material fatigue and increases the risk of component failure. The milder conditions of PECVD extend equipment life and improve process reliability.

Reduced Energy and Fire Risk

Heating a chamber to 800°C requires a massive amount of electrical power. The lower temperature requirement of PECVD results in significantly lower energy consumption, which in turn reduces the inherent fire risk associated with high-power electrical systems.

The Critical Benefit: Substrate and Material Safety

Beyond operator safety, the low-temperature process is essential for protecting the integrity of the materials being processed. In many modern applications, this is the most critical advantage.

Protecting Temperature-Sensitive Substrates

PECVD makes it possible to deposit high-quality films on materials that cannot withstand high heat. This includes polymers, flexible plastics, and organic electronics (like OLEDs), which would melt, warp, or be completely destroyed in a conventional CVD reactor.

Preventing Film and Substrate Degradation

Even on robust substrates like silicon wafers, high temperatures can cause unwanted effects like dopant diffusion or induced film stress. The gentler thermal environment of PECVD helps preserve the properties of underlying layers and results in a more stable final device.

Enhanced Film Integrity and Reliability

The process conditions in PECVD lead to films with fewer cracks and pinholes. A film that is less likely to crack is inherently more reliable and, in applications like protective coatings, safer over its service life.

Understanding the Trade-offs

While thermally safer, PECVD introduces its own set of considerations that must be managed.

Precursor Gas Hazards

PECVD still relies on precursor gases that can be toxic, flammable, or pyrophoric (e.g., silane). The thermal risk is lower, but the chemical handling risk remains. Strict gas handling protocols, cabinet ventilation, and leak detection are non-negotiable.

Potential for Plasma-Induced Damage

The high-energy ions within the plasma can physically bombard the substrate surface. While this can improve film density, it can also cause damage to highly sensitive electronic device structures. This trade-off must be managed by carefully tuning plasma parameters.

Film Contamination

Because the reactions are plasma-assisted, films deposited via PECVD can sometimes have a higher concentration of incorporated impurities, such as hydrogen from precursor gases. For certain high-purity electronic applications, this can be a significant drawback compared to films from high-temperature processes.

Making the Right Choice for Your Goal

Your choice of deposition method depends entirely on the priorities of your specific application.

- If your primary focus is processing temperature-sensitive substrates (like polymers or organic devices): PECVD is often the only viable choice, as its low temperature prevents substrate destruction.

- If your primary focus is maximizing operator safety and reducing facility costs: PECVD significantly lowers thermal risks and energy consumption compared to high-temperature CVD.

- If your primary focus is the absolute highest film purity for critical microelectronics: You must weigh PECVD's benefits against the potential for plasma-induced damage or contamination, where high-temperature LPCVD might still be preferred.

By understanding that PECVD substitutes plasma energy for thermal energy, you can make an informed decision that correctly balances safety, material compatibility, and final film quality.

Summary Table:

| Safety Benefit | Description |

|---|---|

| Reduced Thermal Hazards | Lowers risk of burns and simplifies safety equipment due to temperatures of 200°C-400°C vs. 600°C+ in CVD. |

| Lower Equipment Stress | Extends equipment life by minimizing thermal fatigue on components like seals and chambers. |

| Energy and Fire Risk Reduction | Decreases power consumption and associated fire hazards from high-temperature heating. |

| Substrate Protection | Enables processing of heat-sensitive materials (e.g., polymers, OLEDs) without damage. |

| Enhanced Film Reliability | Produces films with fewer cracks and pinholes, improving long-term safety and performance. |

Upgrade your laboratory's safety and efficiency with KINTEK's advanced PECVD systems! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with high-temperature furnace solutions, including CVD/PECVD Systems, Muffle, Tube, Rotary, and Vacuum & Atmosphere Furnaces. Our strong deep customization capability ensures we precisely meet your unique experimental needs, reducing thermal risks and protecting sensitive materials. Contact us today to discuss how our tailored solutions can benefit your operations!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

People Also Ask

- What is plasma enhanced chemical vapor deposition application? Enable High-Performance Thin Films at Lower Temperatures

- What are the main components of a PECVD system? Unlock Low-Temperature Thin Film Deposition

- What is PECVD equipment? A Guide to Low-Temperature Thin-Film Deposition

- What role does PECVD play in optical coatings? Essential for Low-Temp, High-Precision Film Deposition

- What is the second benefit of deposition within a discharge in PECVD? Enhance Film Quality with Ion Bombardment