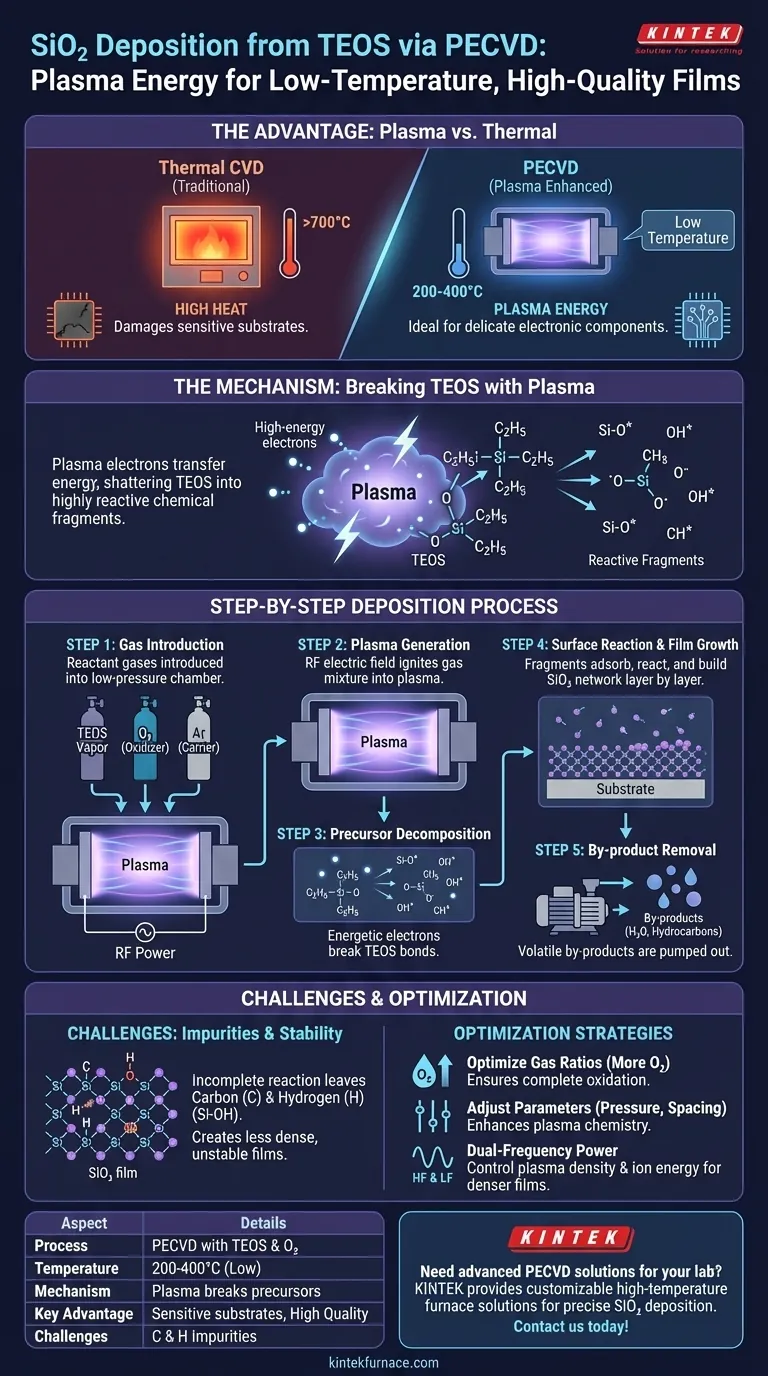

In Plasma Enhanced Chemical Vapor Deposition (PECVD), silicon dioxide is formed from a tetraethylorthosilicate (TEOS) precursor by using plasma energy instead of high heat to drive the chemical reaction. An electric field ignites a mixture of TEOS vapor and an oxygen source (like O2) into a plasma. This process breaks down the precursor molecules into reactive fragments, which then deposit onto a substrate as a thin film of silicon dioxide (SiO2).

The fundamental advantage of using PECVD is its ability to deposit high-quality films at low temperatures (typically 200-400°C). The plasma provides the necessary energy to initiate chemical reactions that would otherwise require much higher heat, making the process ideal for coating temperature-sensitive electronic components.

The Core Mechanism: How Plasma Enables Low-Temperature Deposition

PECVD fundamentally changes how energy is delivered to the chemical system, which is the key to its success.

The Problem with Thermal Methods

Traditional Chemical Vapor Deposition (CVD) relies solely on thermal energy. The substrate must be heated to very high temperatures (often >700°C) to give the precursor gas molecules enough energy to react and form a film.

This high heat can damage or alter underlying layers and devices already fabricated on a wafer, such as aluminum interconnects or other sensitive transistors.

The PECVD Solution: Energy from Plasma, Not Heat

PECVD bypasses the need for high substrate heat by using an electric field to create a plasma, an ionized gas containing a mix of electrons, ions, and neutral species.

High-energy electrons within the plasma collide with the stable TEOS and oxygen gas molecules. These collisions transfer energy and break the molecules apart into highly reactive chemical fragments, known as radicals.

It is these energized radicals that do the work, readily reacting on the cooler substrate surface to form the desired SiO2 film. The plasma effectively provides the activation energy for the reaction, not the hot substrate.

The Step-by-Step Deposition Process

The deposition of SiO2 from TEOS follows a precise sequence inside the PECVD vacuum chamber.

Step 1: Gas Introduction

Reactant gases—typically TEOS vapor and an oxidizer like oxygen (O2)—are introduced into the low-pressure reaction chamber. An inert carrier gas like argon (Ar) may also be used to help stabilize the plasma.

Step 2: Plasma Generation

A high-frequency electric field, usually Radio Frequency (RF), is applied between two electrodes inside the chamber. This field energizes the gas mixture, stripping electrons from some atoms and molecules and igniting the plasma.

Step 3: Precursor Decomposition

The energetic electrons in the plasma collide with the TEOS molecules, breaking their chemical bonds. This decomposition creates a variety of smaller, highly reactive silicon- and oxygen-containing fragments.

Step 4: Surface Reaction and Film Growth

These reactive fragments diffuse to the substrate surface. There, they adsorb, migrate, and undergo a series of chemical reactions to form a stable, solid silicon dioxide (SiO2) network, building up the thin film layer by layer.

Step 5: By-product Removal

The chemical reactions also create volatile by-products (such as hydrocarbons and water from the TEOS molecule). These by-products are continuously removed from the chamber by the vacuum pump system.

Understanding the Trade-offs: Impurities and Film Quality

While powerful, the PECVD TEOS process is not without its challenges. The primary concern is chemical purity and the resulting film stability.

The Challenge of Carbon and Hydrogen

Because TEOS is an organosilicate precursor, incomplete chemical reactions can leave residual carbon (C) and hydrogen (H) trapped in the SiO2 film.

This contamination often exists in the form of silanol groups (Si-OH) or unreacted organic fragments.

Impact of Impurities

These impurities disrupt the silicon-oxygen bond network, creating a less dense and less stable film. Films with high hydrogen content can be unstable in air, absorbing moisture and degrading their electrical properties over time.

Strategies for High-Quality Films

Process engineers use several techniques to minimize contamination and improve film quality. These include:

- Optimizing Gas Ratios: Carefully controlling the ratio of oxygen to TEOS ensures a more complete oxidation reaction.

- Adjusting Process Parameters: Using low pressures and small electrode spacing can enhance the plasma chemistry.

- Using Dual-Frequency Power: Applying both high and low-frequency electrical power can give independent control over plasma density and ion energy, leading to denser, more stable films at high deposition rates.

Making the Right Choice for Your Goal

The optimal process parameters depend entirely on your primary objective for the deposited film.

- If your primary focus is film quality and stability: Prioritize a higher oxygen-to-TEOS ratio and consider using a dual-frequency system to achieve a dense, low-impurity film.

- If your primary focus is protecting a sensitive substrate: The key advantage is PECVD's low temperature; ensure your process temperature remains well below the damage threshold of your device.

- If your primary focus is high deposition rate: Increasing precursor flow rates and RF power can speed up the process, but this often comes at the cost of film quality and uniformity.

Mastering this process is a balancing act between deposition rate, film quality, and the constraints of your substrate.

Summary Table:

| Aspect | Key Details |

|---|---|

| Process | Plasma Enhanced Chemical Vapor Deposition (PECVD) with TEOS precursor and oxygen source |

| Temperature Range | 200-400°C (low temperature) |

| Core Mechanism | Plasma energy breaks TEOS into reactive fragments for SiO2 film growth |

| Key Advantages | Low-temperature operation, suitable for sensitive substrates, high-quality films |

| Common Challenges | Carbon and hydrogen impurities, requiring optimization for film stability |

| Optimization Strategies | Adjust gas ratios, use dual-frequency power, control pressure and electrode spacing |

Need advanced PECVD solutions for your lab? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with high-temperature furnace solutions like CVD/PECVD Systems. Our strong deep customization capability ensures precise meeting of unique experimental requirements for low-temperature, high-quality SiO2 deposition. Contact us today to enhance your process efficiency and film quality!

Visual Guide

Related Products

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

People Also Ask

- What are the applications of PECVD? Unlock Low-Temperature Thin-Film Deposition

- How does PECVD contribute to semiconductor manufacturing? Enable Low-Temperature, High-Quality Film Deposition

- What are the advantages of plasma enhanced CVD? Achieve Low-Temperature, High-Quality Thin Film Deposition

- What are the classifications of CVD based on vapor characteristics? Optimize Your Thin Film Deposition Process

- What parameters control the quality of PECVD-deposited films? Master Key Variables for Superior Film Properties