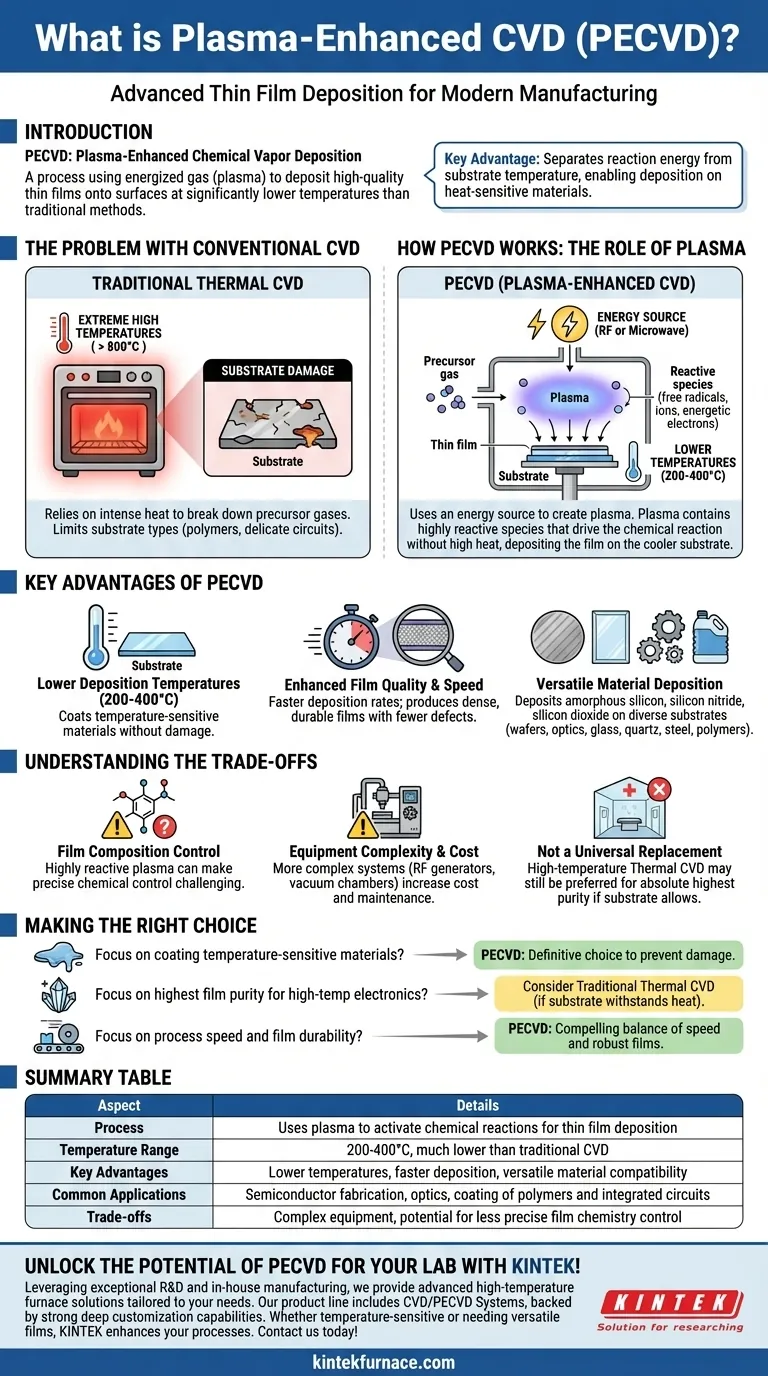

In the world of advanced materials and microfabrication, Plasma-Enhanced Chemical Vapor Deposition (PECVD) is a process used to deposit high-quality thin films onto a surface. Unlike traditional Chemical Vapor Deposition (CVD), which relies on intense heat, PECVD uses an energized gas, or plasma, to drive the chemical reactions. This fundamental difference allows the process to run at much lower temperatures, making it a critical tool for modern manufacturing.

The central advantage of PECVD is its ability to separate the reaction energy from the substrate's temperature. By using plasma to activate precursor gases, it enables the deposition of durable, high-quality thin films onto materials that cannot withstand the extreme heat required by conventional CVD.

The Problem with Conventional Deposition

To understand why PECVD is so important, we must first look at the limitations of its predecessor, traditional Thermal CVD.

The High-Temperature Requirement

Standard CVD works like an oven. It relies exclusively on very high thermal energy to break down chemical precursor gases. The substrate itself must be heated to extreme temperatures for these gases to react and form a film on its surface.

The Substrate Constraint

This dependence on heat severely limits the types of materials that can be coated. Many polymers, plastics, and integrated circuits with delicate components would be damaged or destroyed by the temperatures needed for thermal CVD.

How PECVD Works: The Role of Plasma

PECVD overcomes the temperature barrier by introducing a different kind of energy into the system. It fundamentally changes how the reaction is powered.

Generating the Plasma

Inside the PECVD vacuum chamber, an energy source—typically a radio frequency (RF) or microwave field—is used to ignite the precursor gases. This energy transforms the gas into a plasma.

What is Plasma in this Context?

In this process, plasma is not simply a hot gas. It is a highly energized state of matter containing a mixture of ions, electrons, and, most importantly, highly reactive free radicals. These particles are chemically active without needing high temperatures.

Driving the Reaction with Energy, Not Heat

It is the energetic electrons and reactive radicals within the plasma that break down the precursor gas molecules. These newly formed, reactive chemical species then deposit onto the much cooler substrate, building the desired thin film layer by layer. The plasma provides the energy, not the substrate's heat.

Key Advantages of the PECVD Process

This unique mechanism provides several distinct advantages that are critical for semiconductor fabrication, optics, and other advanced fields.

Lower Deposition Temperatures

This is the primary benefit. PECVD processes often run at temperatures between 200-400°C, a dramatic reduction compared to thermal CVD. This makes it possible to coat temperature-sensitive materials without causing damage.

Enhanced Film Quality and Speed

The highly energetic plasma environment often leads to faster deposition rates than low-temperature thermal methods. The resulting films are typically very dense, durable, and have fewer defects like pinholes.

Versatile Material Deposition

PECVD is used to deposit a wide range of important materials, including amorphous silicon, silicon nitride, and silicon dioxide. It can be applied to diverse substrates such as silicon wafers, optical glass, quartz, and even stainless steel.

Understanding the Trade-offs

While powerful, PECVD is not a universal solution. An objective technical assessment requires acknowledging its trade-offs.

Film Composition Control

The highly reactive and complex nature of plasma can sometimes make it more difficult to precisely control the final film chemistry (stoichiometry). For example, films can sometimes incorporate atoms from the precursor gases, like hydrogen, which may be undesirable for certain electronic applications.

Equipment Complexity and Cost

A PECVD system is more complex than a simple thermal CVD furnace. The need for RF or microwave generators, matching networks, and advanced chamber design increases the equipment's cost and maintenance requirements.

Not a Universal Replacement

For applications where the absolute highest film purity is the only priority and the substrate can tolerate the heat, high-temperature thermal CVD may still be the preferred method. The choice always depends on the specific requirements of the final product.

Making the Right Choice for Your Goal

Your decision to use PECVD should be driven by the specific constraints and desired outcomes of your project.

- If your primary focus is coating temperature-sensitive materials: PECVD is the definitive choice, as its low-temperature process prevents substrate damage while ensuring a high-quality film.

- If your primary focus is achieving the highest possible film purity for high-temperature electronics: You may need to evaluate traditional thermal CVD, assuming your substrate can withstand the intense heat.

- If your primary focus is process speed and film durability on various substrates: PECVD offers a compelling balance of faster deposition rates and robust, dense film properties suitable for a wide array of applications.

Ultimately, understanding that PECVD leverages plasma to replace heat empowers you to select the most effective tool for your material fabrication challenge.

Summary Table:

| Aspect | Details |

|---|---|

| Process | Uses plasma to activate chemical reactions for thin film deposition |

| Temperature Range | 200-400°C, much lower than traditional CVD |

| Key Advantages | Lower temperatures, faster deposition, versatile material compatibility |

| Common Applications | Semiconductor fabrication, optics, coating of polymers and integrated circuits |

| Trade-offs | Complex equipment, potential for less precise film chemistry control |

Unlock the potential of PECVD for your lab with KINTEK! Leveraging exceptional R&D and in-house manufacturing, we provide advanced high-temperature furnace solutions tailored to your needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to precisely meet your unique experimental requirements. Whether you're working with temperature-sensitive materials or need versatile, durable thin films, KINTEK has the expertise and technology to enhance your processes. Contact us today to discuss how we can support your innovation and efficiency goals!

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What forms of energy can be applied in CVD to initiate chemical reactions? Explore Heat, Plasma, and Light for Optimal Thin Films

- What is the difference between PVD and PECVD? Choose the Right Thin-Film Coating Technology

- What are the drawbacks of CVD compared to PECVD? Key Limitations for Your Lab

- How does chemical vapour deposition (CVD) differ from PVD? Key Differences in Thin-Film Coating Methods

- What are gas barrier films, and how is PECVD involved in their creation? Discover Advanced Packaging Solutions