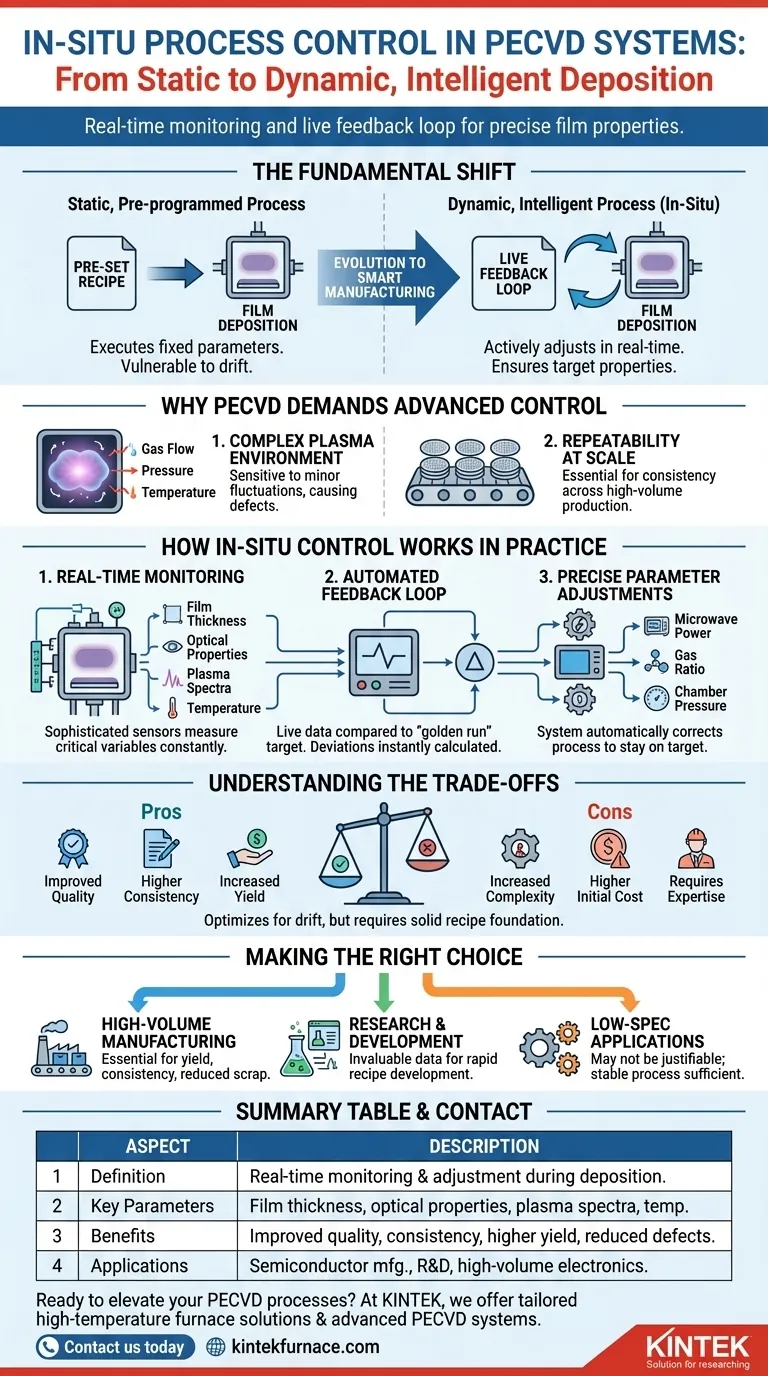

In essence, in-situ process control in a Plasma-Enhanced Chemical Vapor Deposition (PECVD) system is the practice of monitoring key parameters and making real-time adjustments during the film deposition process. Rather than simply executing a pre-set recipe, the system actively uses live feedback to ensure the final material has the exact properties required. This is critical in high-precision fields like semiconductor manufacturing, where even minor deviations can compromise device performance.

The fundamental shift is from a static, pre-programmed deposition to a dynamic, intelligent one. In-situ control acts as a live feedback loop, correcting for process drift as it happens to maximize quality, consistency, and production yield.

Why PECVD Demands Advanced Control

The Challenge: A Complex Plasma Environment

PECVD operates by creating a plasma, an energized state of gas, to deposit thin films at lower temperatures than traditional Chemical Vapor Deposition (CVD). This plasma environment is highly complex and sensitive.

Small, unavoidable fluctuations in factors like gas flow, pressure, or chamber temperature can significantly alter the film's properties, leading to defects or inconsistent results.

The Goal: Repeatability at Scale

The primary advantage of PECVD is its ability to create high-quality materials, such as synthetic diamond or films for 2D electronics, in a scalable and cost-effective manner.

However, achieving this scalability requires absolute consistency from one production run to the next. In-situ control is the mechanism that ensures the thousandth wafer is identical to the first.

How In-Situ Control Works in Practice

Real-Time Monitoring

The process begins with sophisticated sensors placed within the deposition chamber. These sensors do not interfere with the process but constantly measure critical variables.

Commonly monitored parameters include film thickness, optical properties (refractive index), plasma emission spectra, and chamber temperature.

The Automated Feedback Loop

The data from these sensors is fed into a central control unit in real time. This unit compares the live data against a "golden run" or a desired target profile.

If the system detects any deviation—for instance, the film is growing too slowly—it instantly calculates the necessary correction.

Precise Parameter Adjustments

Based on the feedback loop, the system automatically adjusts deposition parameters to bring the process back on target.

This could involve slightly increasing the microwave power to energize the plasma, altering the ratio of precursor gases, or adjusting the chamber pressure to modify the deposition rate.

Understanding the Trade-offs

Increased System Complexity and Cost

Implementing robust in-situ control requires additional hardware (sensors, analyzers) and sophisticated software. This increases the initial capital investment and complexity of the PECVD system.

The Need for Process Expertise

The data generated by in-situ sensors must be correctly interpreted to be useful. This requires either deep process knowledge to set up the control algorithms or advanced machine learning models to manage the feedback loop autonomously.

It Optimizes, It Doesn't Fix

In-situ control is exceptionally good at correcting for minor process drift and variability. However, it cannot compensate for a fundamentally flawed or poorly designed deposition recipe. The foundation must be solid.

Making the Right Choice for Your Goal

Deciding on the level of in-situ control depends entirely on your end goal.

- If your primary focus is high-volume manufacturing: In-situ control is essential for maximizing yield, reducing scrap, and ensuring the device-to-device consistency demanded by consumer, automotive, and medical electronics.

- If your primary focus is research and development: In-situ monitoring provides invaluable data for understanding process dynamics, allowing you to develop and optimize new material recipes far more quickly.

- If your primary focus is cost-sensitive, lower-spec applications: The higher initial cost may not be justifiable, and a well-characterized, stable process without real-time control may be sufficient.

Ultimately, adopting in-situ process control is an investment in turning your manufacturing process from a variable art into a predictable science.

Summary Table:

| Aspect | Description |

|---|---|

| Definition | Real-time monitoring and adjustment of parameters during PECVD film deposition for precise control. |

| Key Parameters Monitored | Film thickness, optical properties, plasma emission spectra, chamber temperature. |

| Benefits | Improved film quality, consistency, higher production yield, reduced defects. |

| Applications | Semiconductor manufacturing, R&D for new materials, high-volume electronics production. |

Ready to elevate your PECVD processes with advanced in-situ control? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide tailored high-temperature furnace solutions, including our advanced PECVD systems. Our strong deep customization capability ensures we meet your unique experimental and production needs, helping you achieve superior film quality and yield. Contact us today to discuss how we can optimize your lab's efficiency and results!

Visual Guide

Related Products

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What are the advantages of using CVD? Achieve High-Purity, Conformal Thin Films for Your Applications

- What parameters control the quality of PECVD-deposited films? Master Key Variables for Superior Film Properties

- What is plasma-deposited silicon nitride, and what are its properties? Discover Its Role in Solar Cell Efficiency

- How does chemical vapour deposition (CVD) differ from PVD? Key Differences in Thin-Film Coating Methods

- How does PECVD contribute to semiconductor manufacturing? Enable Low-Temperature, High-Quality Film Deposition