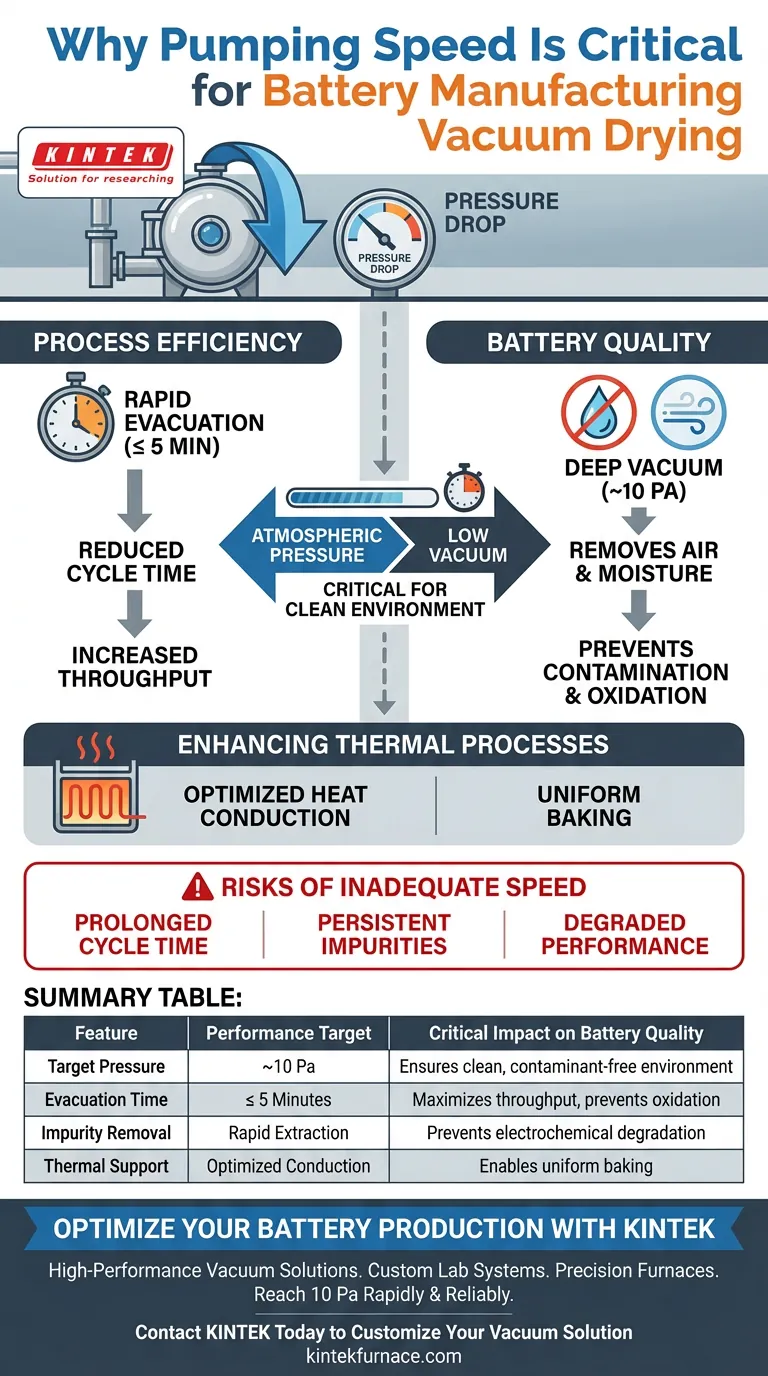

The pumping speed of a vacuum drying system is the defining factor for both process efficiency and battery quality. It dictates the ability to rapidly drop chamber pressure from atmospheric levels to a functional low vacuum of approximately 10 Pa, ideally within a brief five-minute window. This acceleration is not merely about saving time; it is a critical requirement for removing contaminants that degrade battery performance.

A high-performance pumping system is essential to bridge the gap between atmospheric pressure and a clean processing environment. By achieving a deep vacuum quickly, manufacturers ensure the effective removal of air and moisture, paving the way for consistent heat conduction and optimal baking efficiency.

The Mechanics of Rapid Evacuation

Achieving Target Pressure

The primary function of pumping speed is to traverse the pressure gradient efficiently. The goal is to reduce the chamber pressure to a low vacuum state, specifically around 10 Pa.

Time Constraints and Efficiency

Time is a critical variable in this process. A high-performance system is characterized by its ability to reach this target pressure within a short timeframe, such as five minutes.

Impact on Battery Quality

Eliminating Contaminants

Rapid evacuation is the primary mechanism for cleaning the chamber environment. It efficiently removes air and moisture, which are significant impurities in battery manufacturing.

Minimizing Impurity Impact

By removing these elements quickly, the system minimizes the impact of impurities on the battery materials. This ensures a clean physical environment is established before the drying or baking phases fully commence.

Enhancing Thermal Processes

Improving Baking Efficiency

The speed of the vacuum drawdown directly supports the baking process. A rapidly established vacuum allows the baking phase to operate at maximum efficiency without interference from atmospheric gases.

Facilitating Heat Conduction

Once the vacuum is established, it creates the necessary conditions for thermal transfer. The removal of air allows for subsequent heat conduction to occur in a controlled manner, ensuring uniform treatment of the battery components.

The Risks of Inadequate Speed

Environmental Instability

If the pumping speed is insufficient, the transition to 10 Pa is prolonged. This delay allows residual environmental pressure to linger, potentially interfering with the consistency of the drying process.

Persistent Impurities

A slow evacuation fails to scour the chamber effectively. This can lead to trapped moisture or air pockets, which directly compromise the electrochemical performance of the final battery product.

Making the Right Choice for Your Goal

When selecting or evaluating a vacuum drying system for battery production, focus on the system's ability to handle the pressure drop within specific time limits.

- If your primary focus is Production Throughput: Ensure the system can reach 10 Pa within five minutes to minimize downtime between cycles.

- If your primary focus is Product Quality: Prioritize pumping speed to guarantee the rapid and complete evacuation of moisture and air before heat conduction begins.

Speed in vacuum drying is not just a metric of pace; it is a fundamental control for purity and performance.

Summary Table:

| Feature | Performance Target | Critical Impact on Battery Quality |

|---|---|---|

| Target Pressure | ~10 Pa | Ensures a clean, contaminant-free environment |

| Evacuation Time | ≤ 5 Minutes | Maximizes throughput and prevents material oxidation |

| Impurity Removal | Rapid Air/Moisture Extraction | Prevents degradation of electrochemical properties |

| Thermal Support | Optimized Heat Conduction | Enables uniform baking and consistent drying results |

Optimize Your Battery Production with KINTEK

Don't let inadequate vacuum speed compromise your battery performance. Backed by expert R&D and manufacturing, KINTEK offers high-performance Vacuum, CVD, and customizable lab systems designed to reach 10 Pa targets rapidly and reliably. Our advanced high-temp furnaces are engineered for precision, ensuring your materials are free from moisture and air contamination.

Ready to enhance your lab’s drying efficiency and product purity?

Contact KINTEK Today to Customize Your Vacuum Solution

Visual Guide

References

- Lili Zhao, Bo Qi. Research on Temperature Field Characteristics of Lithium Battery Vacuum Drying Furnace. DOI: 10.56028/aetr.11.1.63.2024

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- What processes can vacuum carburizing furnaces perform? Unlock Versatile Heat Treatment Solutions

- How does a vacuum impregnation device facilitate PCMs into biomimetic composites? Boost Filling Rates to 96%

- What is a vacuum atmosphere and when is it used? Achieve Material Purity and Integrity in High-Temp Processes

- How does a vertical vacuum furnace separate magnesium, zinc, and aluminum? Exploit Boiling Points for Metal Recovery

- What is the role of the heat exchanger in vacuum gas quenching? Optimize Cooling Intensity & Metal Hardness

- What are the steps involved in the vacuum sintering process? Master Precision and Purity for Superior Materials

- What is the importance of a high vacuum pumping system in FGH96 alloy degassing? Ensure Superior Material Integrity

- How does the evacuation process work in a vacuum furnace? Achieve Precise Metallurgical Control