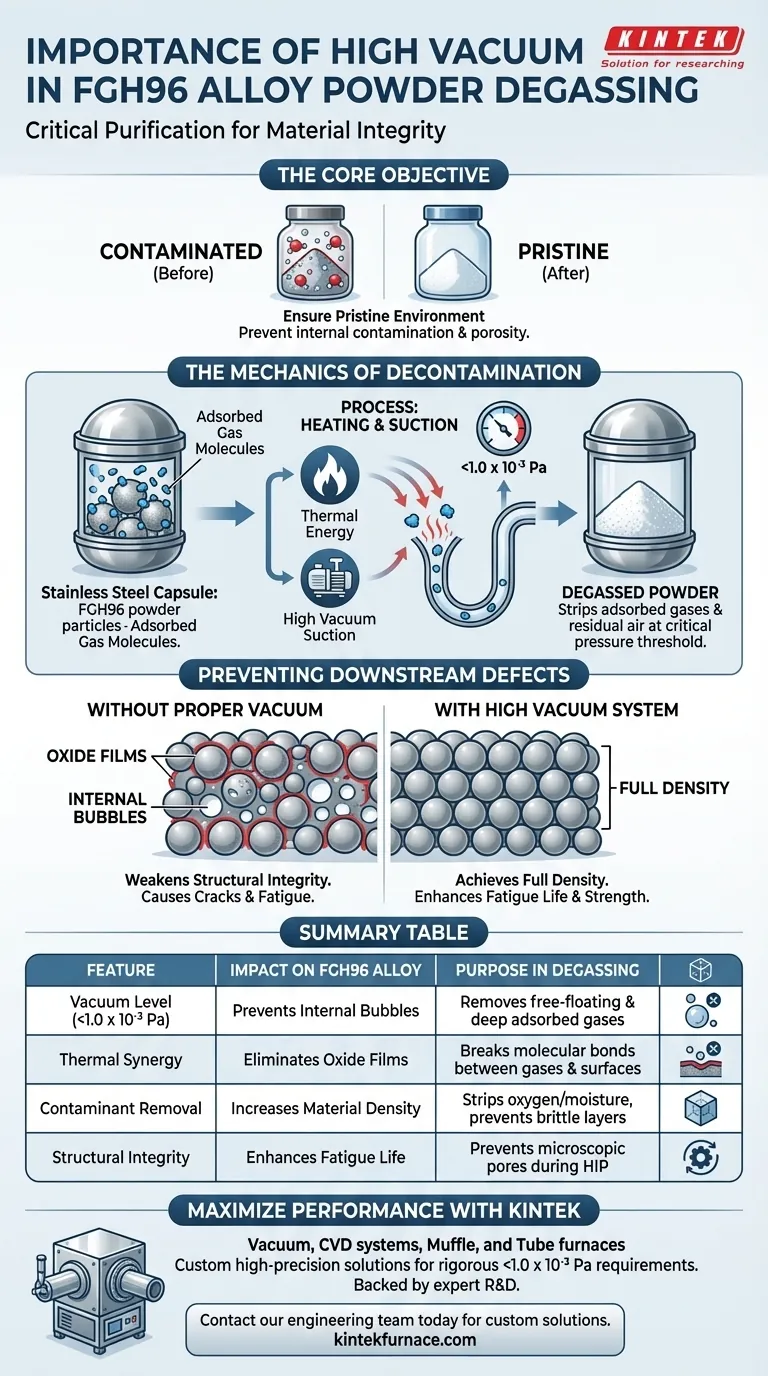

A high vacuum pumping system serves as the critical purification stage in the processing of FGH96 alloy powders. Its primary function is to evacuate the environment within stainless steel capsules to a pressure lower than 1.0 x 10^-3 Pa, stripping away adsorbed gases and residual air from the powder surfaces before the capsule is sealed.

The Core Objective: High-performance alloys cannot tolerate internal contamination. The vacuum system ensures material integrity by creating a pristine environment that prevents chemical reactions and porosity during the high-temperature consolidation process.

The Mechanics of Decontamination

Reaching the Critical Pressure Threshold

The effectiveness of the degassing process is defined by the vacuum level. For FGH96 powders, simply reducing pressure is insufficient; the system must achieve a high vacuum state of less than 1.0 x 10^-3 Pa.

At this specific pressure tier, the system is not just removing free-floating air. It is actively detaching gas molecules that are physically adhered (adsorbed) to the surface of the powder particles.

The Synergy of Heating and Suction

Vacuum alone is often not enough to dislodge stubborn surface contaminants. The system utilizes a combination of heating and suction.

Thermal energy excites the gas molecules trapped on the powder surface, breaking their bond with the metal. Simultaneously, the high vacuum pump creates the negative pressure required to siphon these liberated gases out of the stainless steel capsule immediately.

Preventing Downstream Defects

Eliminating Oxide Films

The presence of residual oxygen is fatal to the quality of FGH96 alloys. If air remains during the subsequent Hot Isostatic Pressing (HIP) stage, the high temperatures will cause the oxygen to react with the metal.

This reaction forms oxide films—thin, brittle layers between powder particles. These films act as cracks waiting to happen, severely weakening the structural integrity of the final component.

Avoiding Internal Bubble Formation

Gases trapped inside the capsule do not disappear; they expand or remain as voids when heated.

By removing these gases prior to encapsulation, the pumping system prevents the formation of internal bubbles. This ensures that when the material is consolidated, it achieves full density without the microscopic pores that compromise fatigue life and strength.

Common Pitfalls to Avoid

Insufficient Vacuum Levels

A "rough" vacuum is not a substitute for high vacuum. Failing to reach the specific 1.0 x 10^-3 Pa benchmark leaves residual contaminants behind. Even trace amounts of gas can lead to defects that are undetectable until the part fails under stress.

Ignoring Thermal Assistance

Relying solely on pumping speed without adequate temperature control can lead to incomplete degassing. Just as solvents require heat to evaporate effectively in other alloy processes, adsorbed gases in FGH96 require thermal energy to release fully from the particle surface.

Making the Right Choice for Your Goal

To ensure the success of your FGH96 encapsulation process, align your vacuum strategy with your specific quality metrics:

- If your primary focus is Material Density: Prioritize a pumping system capable of sustaining pressures significantly below 1.0 x 10^-3 Pa to eliminate all sources of bubble formation.

- If your primary focus is Mechanical Strength: Ensure your process strictly combines heating with vacuum to fully strip potential oxide-forming layers from particle boundaries.

The vacuum pumping system is not merely a step in the process; it is the guarantee that the powder's potential becomes the alloy's performance.

Summary Table:

| Feature | Impact on FGH96 Alloy | Purpose in Degassing |

|---|---|---|

| Vacuum Level (<1.0 x 10^-3 Pa) | Prevents Internal Bubbles | Removes free-floating air and deep adsorbed gases. |

| Thermal Synergy | Eliminates Oxide Films | Breaks molecular bonds between gases and powder surfaces. |

| Contaminant Removal | Increases Material Density | Strips oxygen/moisture to prevent brittle boundary layers. |

| Structural Integrity | Enhances Fatigue Life | Prevents microscopic pores during Hot Isostatic Pressing (HIP). |

Maximize Your Material Performance with KINTEK

Don't let residual gases compromise the structural integrity of your high-performance alloys. Backed by expert R&D and manufacturing, KINTEK offers high-precision Vacuum, CVD systems, Muffle, and Tube furnaces—all fully customizable to meet the rigorous 1.0 x 10^-3 Pa requirements of FGH96 degassing and other specialized lab high-temp needs.

Ready to achieve zero-defect consolidation? Contact our engineering team today to design a custom heating and vacuum solution tailored to your unique specifications.

Visual Guide

References

- Yufeng Liu, Guoqing Zhang. Effects of Oxygen Content on Microstructure and Creep Property of Powder Metallurgy Superalloy. DOI: 10.3390/cryst14040358

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Magnesium Extraction and Purification Condensing Tube Furnace

People Also Ask

- Why is a high-vacuum environment necessary for gold electrode deposition? Key to Solar Cell Efficiency

- How does the digital display intelligent temperature control system work in vacuum sintering furnaces? Achieve Precise Thermal Management

- How does the design of a vacuum furnace contribute to its energy efficiency? Maximize Thermal Performance & Reduce Costs

- How does graphite contribute to energy efficiency in vacuum furnaces? Achieve Faster, More Uniform Heating

- What is the significance of a multi-cathode vacuum chamber configuration? Boost DLC Coating Efficiency & Adhesion

- What is the function of the crystallizer in a vacuum sublimation furnace? Mastering Temperature for High-Purity Magnesium

- Why is prolonged treatment in a vacuum drying oven necessary for SnO2-based anodes? Ensure Reliable Electrochemical Data

- What are the applications of furnace brazing in the energy and power generation sector? Achieve Superior Joint Integrity for Critical Components