A multi-cathode vacuum chamber configuration significantly enhances industrial coating efficiency by enabling the continuous deposition of complex, multi-layer structures within a single cycle. By utilizing multiple distinct targets—specifically chromium for adhesion and graphite for the functional layer—this setup allows for flexible magnetic field configurations and the creation of gradient coatings without breaking the vacuum.

By integrating multiple material sources into one chamber, manufacturers eliminate the need for mid-process target swaps. This ensures that complex coating sequences, from the base interface to the top Diamond-Like Carbon (DLC) surface, are achieved with superior consistency and production speed.

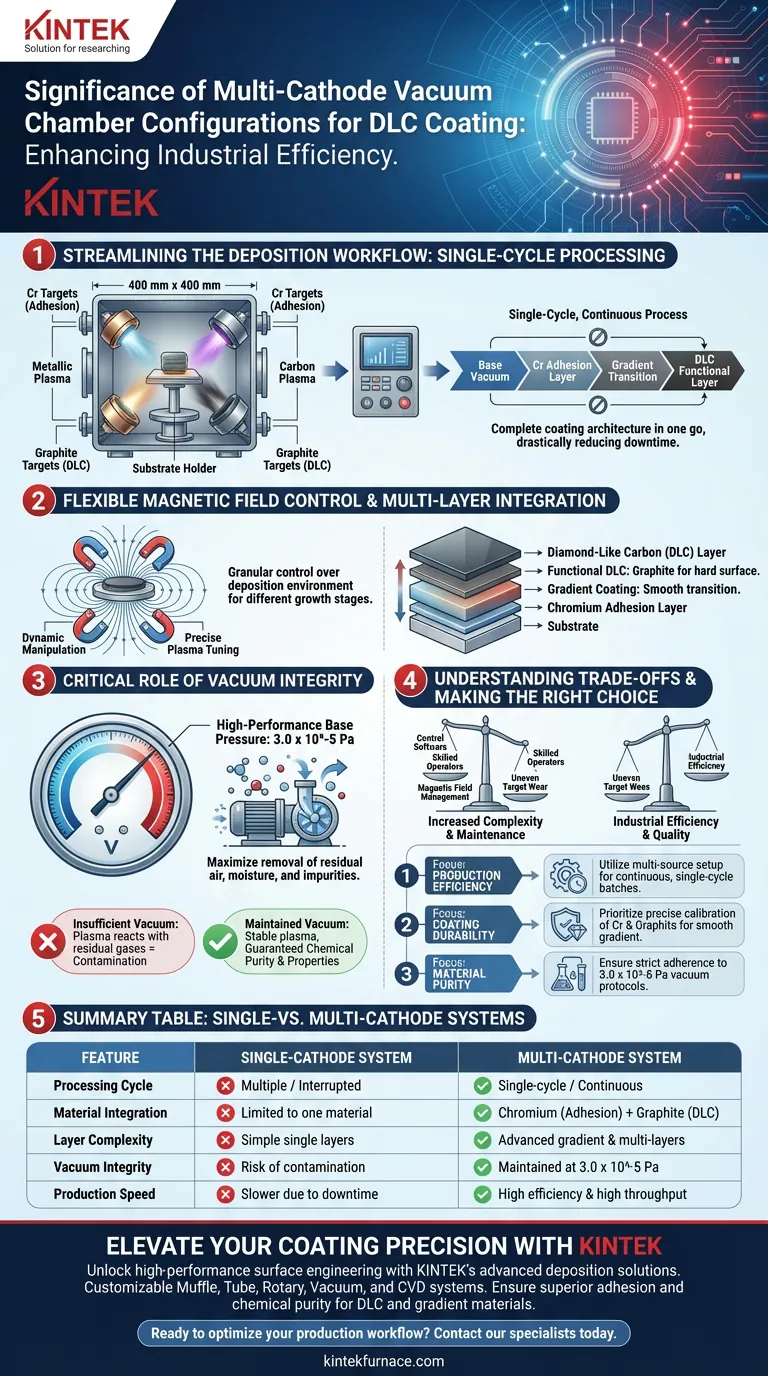

Streamlining the Deposition Workflow

The Advantage of Single-Cycle Processing

In a standard industrial setup, such as a 400 mm x 400 mm chamber, a four-cathode configuration changes the production paradigm.

Instead of running separate batches for different layers, the system can complete the entire coating architecture in one go.

This drastically reduces downtime associated with venting the chamber or changing equipment setups between layers.

Flexible Magnetic Field Control

The use of four dedicated cathodes provides granular control over the deposition environment.

Operators can manipulate magnetic field configurations dynamically during the process.

This flexibility allows for precise tuning of plasma characteristics to suit different stages of the coating growth.

Achieving Multi-Layer Material Integration

Establishing Robust Adhesion

The primary challenge in DLC coating is ensuring the hard carbon layer sticks to the substrate.

To solve this, specific cathodes are loaded with chromium targets to deposit an initial adhesion layer.

This creates a strong chemical bond with the substrate, preventing delamination under stress.

Creating Functional DLC Layers

Once the adhesion layer is established, the system switches control to cathodes equipped with graphite targets.

This transition allows for the deposition of the functional Diamond-Like Carbon layer.

By gradually shifting between sources, the system creates a gradient coating, smoothing the transition between the metal interface and the hard carbon surface.

The Critical Role of Vacuum Integrity

Reaching High-Performance Base Pressure

The effectiveness of a multi-cathode system relies heavily on the purity of the vacuum environment.

Prior to deposition, high-performance pumps reduce the base pressure to $3.0 \times 10^{-5}$ Pa.

This deep vacuum is necessary to maximize the removal of residual air molecules, moisture, and impurity gases.

Ensuring Chemical Purity

If the vacuum level is insufficient, active carbon atoms in the plasma will react with residual gases.

Maintaining the $3.0 \times 10^{-5}$ Pa threshold ensures the plasma discharge remains stable.

This prevents contamination, guaranteeing the doped DLC coating maintains its accurate chemical composition and physical properties.

Understanding the Trade-offs

Increased System Complexity

While efficient, a multi-cathode system introduces more variables into the manufacturing equation.

Balancing the interactions between four different sources requires sophisticated control software and skilled operators.

Mismanagement of the magnetic fields can lead to uneven coating thickness or target poisoning.

Maintenance Considerations

Managing four distinct cathodes requires vigilant maintenance protocols.

Operators must monitor target erosion rates across chromium and graphite sources simultaneously.

Uneven wear on targets can alter the deposition rate, potentially affecting the gradient structure if not corrected.

Making the Right Choice for Your Goal

To leverage a multi-cathode system effectively, align your configuration with your specific production targets:

- If your primary focus is Production Efficiency: Utilize the multi-source setup to run continuous, single-cycle batches to minimize downtime between layers.

- If your primary focus is Coating Durability: Prioritize the precise calibration of Chromium and Graphite targets to create a smooth gradient that maximizes adhesion.

- If your primary focus is Material Purity: Ensure your vacuum protocols strictly adhere to the $3.0 \times 10^{-5}$ Pa standard to prevent chemical degradation of the DLC layer.

The multi-cathode configuration is not just about adding more hardware; it is about creating a unified, versatile environment that turns complex chemical processes into reliable industrial routines.

Summary Table:

| Feature | Single-Cathode System | Multi-Cathode System |

|---|---|---|

| Processing Cycle | Multiple cycles / Interrupted | Single-cycle / Continuous |

| Material Integration | Limited to one material | Chromium (Adhesion) + Graphite (DLC) |

| Layer Complexity | Simple single layers | Advanced gradient & multi-layers |

| Vacuum Integrity | Risk of contamination during swaps | Maintained at $3.0 \times 10^{-5}$ Pa |

| Production Speed | Slower due to downtime | High efficiency & high throughput |

Elevate Your Coating Precision with KINTEK

Unlock the full potential of high-performance surface engineering with KINTEK’s advanced deposition solutions. Backed by expert R&D and world-class manufacturing, KINTEK offers customizable Muffle, Tube, Rotary, Vacuum, and CVD systems designed to meet the rigorous demands of modern industrial labs.

Whether you are developing durable Diamond-Like Carbon (DLC) coatings or specialized gradient materials, our systems provide the vacuum integrity and process control you need to ensure superior adhesion and chemical purity.

Ready to optimize your production workflow? Contact our specialists today to find the perfect high-temperature furnace or vacuum system tailored to your unique research and manufacturing needs.

Visual Guide

References

- Eneko Barba, J.A. Garcı́a. Study of the Industrial Application of Diamond-Like Carbon Coatings Deposited on Advanced Tool Steels. DOI: 10.3390/coatings14020159

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- Why Use PECVD for Monolithic Integrated Chip Isolation Layers? Protect Your Thermal Budget with High-Quality SiO2

- What is the function of a PECVD system in the passivation of UMG silicon solar cells? Enhance Efficiency with Hydrogen

- What environments does a PECVD system provide for silicon nanowires? Optimize Growth with Precise Thermal Control

- What is the room temperature for PECVD? Unlock Low-Temp Thin Film Deposition

- What methods are used to analyze and characterize graphene samples? Unlock Key Techniques for Accurate Material Analysis