Yes, Plasma-Enhanced Chemical Vapor Deposition (PECVD) can be performed at room temperature. However, its typical operating range is between 200°C and 400°C. The ability to function at room temperature represents the lower extreme of its capability and is a key advantage over standard CVD processes, which require much higher heat.

The critical insight is not that PECVD can run at room temperature, but why. By using an energy-rich plasma to drive chemical reactions instead of high heat, PECVD decouples the deposition process from the substrate's temperature, enabling high-quality film growth on heat-sensitive materials.

The Role of Plasma in Lowering Deposition Temperature

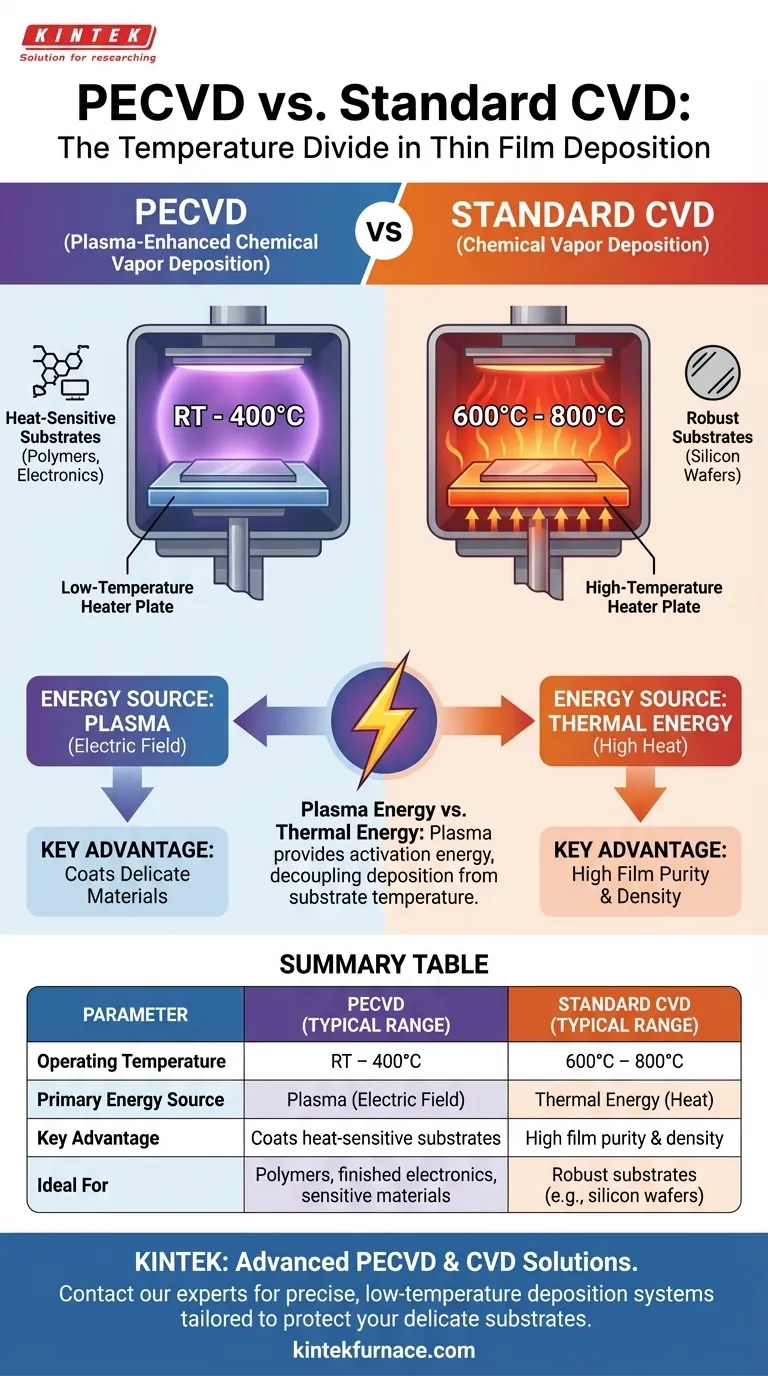

To understand why PECVD can operate at low temperatures, we must first contrast it with its thermal predecessor, standard Chemical Vapor Deposition (CVD).

How Standard CVD Uses Thermal Energy

In a traditional CVD process, the substrate is heated to very high temperatures, typically between 600°C and 800°C.

This intense thermal energy is required to break down the precursor gases and provide the activation energy for the chemical reactions that form the thin film on the substrate surface.

How PECVD Uses Plasma Energy

PECVD replaces the need for extreme heat with an electric field, which ignites the precursor gases into a plasma.

This plasma is a highly energetic state of matter containing ions, electrons, and free radicals. These reactive species have enough energy to drive the deposition reaction, even at much lower substrate temperatures.

Essentially, the plasma provides the activation energy, not the heat. This allows the substrate to remain at a temperature that won't damage it.

Comparing Temperature Ranges: PECVD vs. CVD

The fundamental difference in energy sources leads to drastically different operating windows for these two technologies.

The Advantage of PECVD's Low-Temperature Range

PECVD typically operates from room temperature up to around 350°C or 400°C.

This low-temperature window is the system's defining feature. It makes it possible to deposit films on materials that cannot withstand high thermal loads, such as polymers, plastics, and fully fabricated semiconductor devices with sensitive integrated circuits.

The High-Temperature Demands of Standard CVD

Standard CVD processes require temperatures in the 600°C to 800°C range.

While this produces very high-quality, dense, and pure films, it severely restricts the types of substrates that can be used. It is suitable for robust materials like silicon wafers early in the fabrication process but is incompatible with most finished devices or temperature-sensitive materials.

Understanding the Trade-offs

Choosing a deposition temperature is not just about protecting the substrate; it also involves balancing film quality, deposition rate, and process complexity.

The Primary Advantage: Substrate Versatility

The ability to deposit films at or near room temperature is the single greatest advantage of PECVD. It opens the door to coating materials that would be destroyed by the heat of other vapor deposition methods.

Potential Impact on Film Quality

While PECVD produces excellent films, deposition at the lowest end of the temperature range (i.e., room temperature) can involve trade-offs.

Lower temperatures can sometimes lead to less dense films or incorporate more impurities, such as hydrogen, from the precursor gases. Often, operating at a slightly elevated temperature (e.g., 200-350°C) provides a better balance of substrate safety and optimal film properties.

Process Control

The use of plasma introduces more process variables than standard CVD, including RF power, frequency, pressure, and gas flow rates.

Mastering these parameters is key to controlling the film's properties, such as stress, refractive index, and chemical composition, independent of the temperature.

Making the Right Choice for Your Application

Your choice of deposition temperature should be dictated by your primary goal and the limitations of your substrate.

- If your primary focus is compatibility with heat-sensitive substrates (like polymers or electronics): PECVD is the clear choice, as its low-temperature capability, including room temperature, prevents thermal damage.

- If your primary focus is achieving maximum film density and purity for a robust substrate: You should operate at the higher end of the PECVD range (250-400°C) or consider if a high-temperature CVD process is viable.

Ultimately, PECVD's low-temperature flexibility empowers you to engineer advanced thin films on materials that would otherwise be impossible to coat.

Summary Table:

| Parameter | PECVD (Typical Range) | Standard CVD (Typical Range) |

|---|---|---|

| Operating Temperature | Room Temp - 400°C | 600°C - 800°C |

| Primary Energy Source | Plasma (Electric Field) | Thermal Energy (Heat) |

| Key Advantage | Coats heat-sensitive substrates | High film purity & density |

| Ideal For | Polymers, finished electronics, sensitive materials | Robust substrates (e.g., silicon wafers) |

Need to deposit high-quality thin films on heat-sensitive materials? KINTEK's advanced PECVD systems leverage our deep R&D and in-house manufacturing to deliver precise, low-temperature deposition solutions. Our systems, including our customizable PECVD and CVD/PECVD Systems, are engineered to protect your delicate substrates while achieving optimal film properties. Contact our experts today to discuss how we can tailor a high-temperature furnace solution for your unique laboratory requirements.

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

People Also Ask

- How does a CVD system ensure the quality of carbon layers? Achieving Nanometer Precision with KINTEK

- How does a PECVD system contribute to (n)poly-Si layers? High-Throughput In-Situ Doping Explained

- What is the function of a PECVD system in the passivation of UMG silicon solar cells? Enhance Efficiency with Hydrogen

- What is the necessity of high-bias gas ion cleaning? Achieve Atomic-Level Coating Adhesion

- Why is a high-precision PECVD system required in ACSM? Enable Low-Temperature Atomic-Scale Manufacturing