At its core, the energy efficiency of a vacuum furnace is achieved through a multi-faceted design philosophy that minimizes heat loss and optimizes energy consumption. This is accomplished primarily through the use of advanced insulation materials, intelligent control systems, and a chamber engineered to leverage the vacuum itself as a superior insulator.

The central principle behind a vacuum furnace's efficiency is not a single component, but a holistic system design. Every element, from the hot zone materials to the vacuum pump, is engineered to prevent thermal energy from escaping and to use only the precise amount of electrical energy needed for the process.

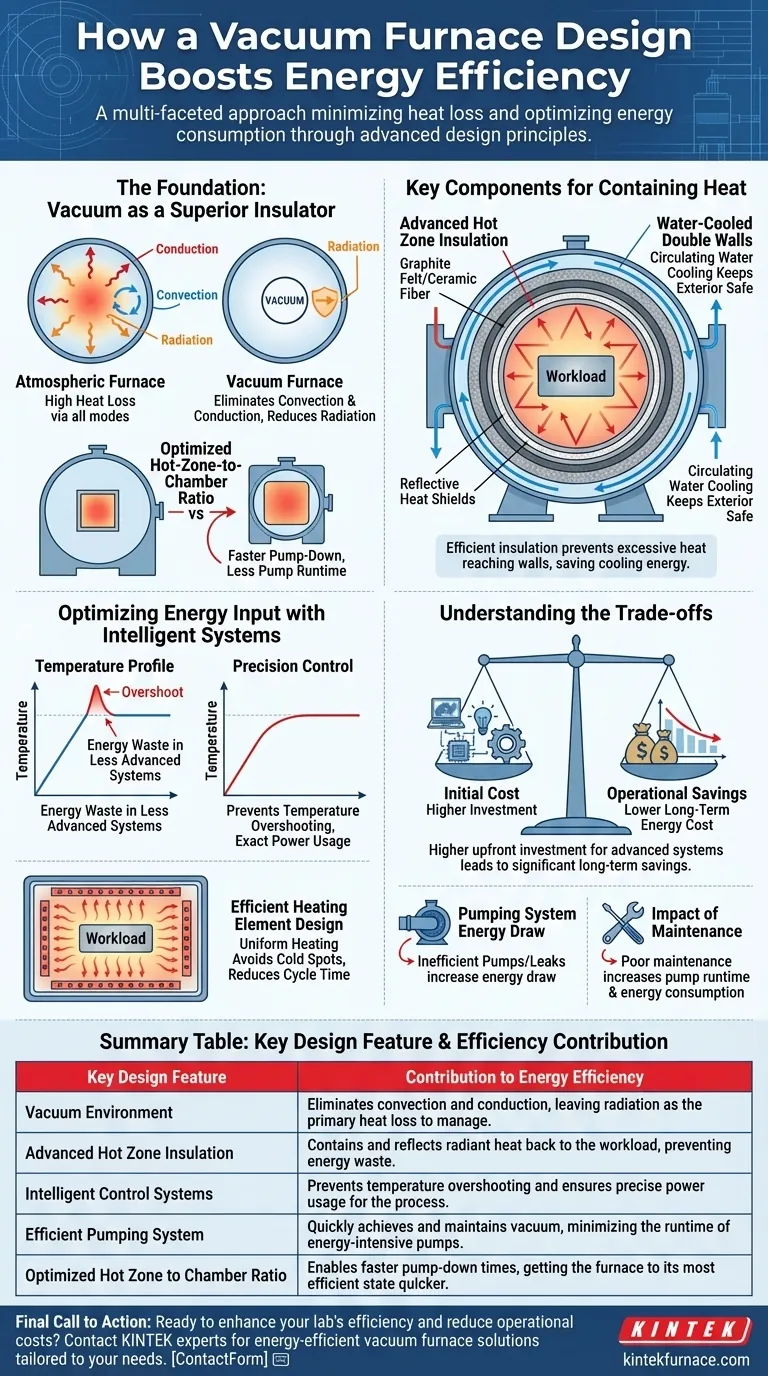

The Foundation: Vacuum as a Superior Insulator

The most fundamental design element contributing to a vacuum furnace's efficiency is the vacuum environment itself. By removing air, the design drastically reduces two of the three modes of heat transfer.

Eliminating Convection and Conduction

Heat naturally moves from hot to cold areas through conduction, convection, and radiation. A vacuum, by removing the vast majority of air molecules, effectively eliminates heat transfer by convection and significantly reduces conduction.

This leaves radiation as the primary method of heat loss, allowing designers to focus their efforts on containing it with specialized materials.

Optimizing the Hot-Zone-to-Chamber Ratio

An efficient design features a carefully calculated ratio between the heated internal volume (the "hot zone") and the total chamber volume.

A smaller, tighter ratio enables the pumping system to reach the required vacuum level more quickly. This reduces the runtime of energy-intensive vacuum pumps and gets the furnace into its most efficient operating state faster.

Key Components for Containing Heat

While the vacuum provides the environment, physical components are engineered to manage the remaining thermal energy, primarily heat radiation.

Advanced Hot Zone Insulation

The "hot zone" is the heart of the furnace and is lined with layers of advanced insulation. Materials like graphite felt, ceramic fiber, or reflective metallic heat shields are used to contain and reflect radiant heat back toward the workload.

The quality, thickness, and type of this insulation package are the most critical factors in preventing energy from escaping the hot zone and being wasted.

Water-Cooled Double Walls

The outer chamber of a vacuum furnace is typically a double-walled vessel cooled with circulating water. This keeps the exterior of the furnace safe to touch.

However, this design underscores the importance of the internal hot zone insulation. Inefficient insulation would allow excessive heat to reach the chamber walls, forcing the water-cooling system to work harder and dump massive amounts of energy.

Optimizing Energy Input with Intelligent Systems

Preventing heat loss is only half of the equation. Efficiently managing the energy used to generate the heat is equally critical.

Precision Control Systems

Modern vacuum furnaces utilize sophisticated control systems. These systems precisely regulate the power sent to the heating elements, allowing for controlled temperature ramp rates and exact holding temperatures.

This prevents temperature overshooting, a common source of wasted energy in less advanced systems, and ensures no more power is consumed than is absolutely necessary for the metallurgical process.

Efficient Heating Element Design

The design, material (e.g., graphite or molybdenum), and placement of the heating elements are engineered for maximum heat transfer to the workpiece.

By ensuring uniform heating, the furnace avoids "cold spots," which would otherwise require longer cycle times or higher overall temperatures to process the entire load, both of which waste energy.

Understanding the Trade-offs

While highly efficient, the design of a vacuum furnace presents specific considerations that impact its overall performance and cost.

Initial Cost vs. Operational Savings

Furnaces with the most advanced, multi-layered insulation packages and sophisticated control systems have a higher upfront investment. This cost is weighed against significant long-term savings in operational energy costs.

Pumping System Energy Draw

The vacuum pumps themselves are major energy consumers. A poorly sealed chamber or an inefficient pump design can negate the thermal efficiency of the hot zone by requiring constant, high-power operation to maintain the vacuum.

The Impact of Maintenance

Even the best design is compromised by poor maintenance. A small air leak forces the vacuum pumps to work continuously, dramatically increasing energy consumption and potentially compromising the quality of the work being processed.

Making the Right Choice for Your Goal

Selecting a furnace requires matching its design characteristics to your primary operational objective.

- If your primary focus is maximum thermal efficiency: Prioritize designs with thick, multi-layered graphite or all-metal radiation shield insulation and a tight hot-zone-to-chamber ratio.

- If your primary focus is rapid throughput: Look for a furnace with a powerful, high-capacity vacuum pumping system paired with low-mass insulation for faster heating and cooling cycles.

- If your primary focus is long-term cost reduction: Analyze the entire system, including the energy ratings of the pumps and control systems, not just the thermal efficiency of the hot zone.

A truly energy-efficient vacuum furnace is an integrated system where every component is designed to retain and utilize energy with minimal waste.

Summary Table:

| Key Design Feature | Contribution to Energy Efficiency |

|---|---|

| Vacuum Environment | Eliminates convection and conduction, leaving radiation as the primary heat loss to manage. |

| Advanced Hot Zone Insulation | Contains and reflects radiant heat back to the workload, preventing energy waste. |

| Intelligent Control Systems | Prevents temperature overshooting and ensures precise power usage for the process. |

| Efficient Pumping System | Quickly achieves and maintains vacuum, minimizing the runtime of energy-intensive pumps. |

| Optimized Hot Zone to Chamber Ratio | Enables faster pump-down times, getting the furnace to its most efficient state quicker. |

Ready to enhance your lab's efficiency and reduce operational costs?

At KINTEK, we leverage our exceptional R&D and in-house manufacturing to provide advanced, energy-efficient vacuum furnace solutions. Our product line, including high-performance Vacuum & Atmosphere Furnaces and CVD/PECVD Systems, is complemented by strong deep customization capabilities. We can precisely engineer a furnace to meet your unique thermal processing requirements, ensuring maximum energy savings and performance.

Contact our experts today to discuss how a KINTEK vacuum furnace can be the optimal solution for your laboratory.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- How does a vacuum heat treatment furnace influence Ti-6Al-4V microstructure? Optimize Ductility and Fatigue Resistance

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- What are the benefits of vacuum heat treatment? Achieve Superior Metallurgical Control

- What is the vacuum heat treatment process? Achieve Superior Surface Quality and Material Performance

- What are the components of a vacuum furnace? Unlock the Secrets of High-Temperature Processing