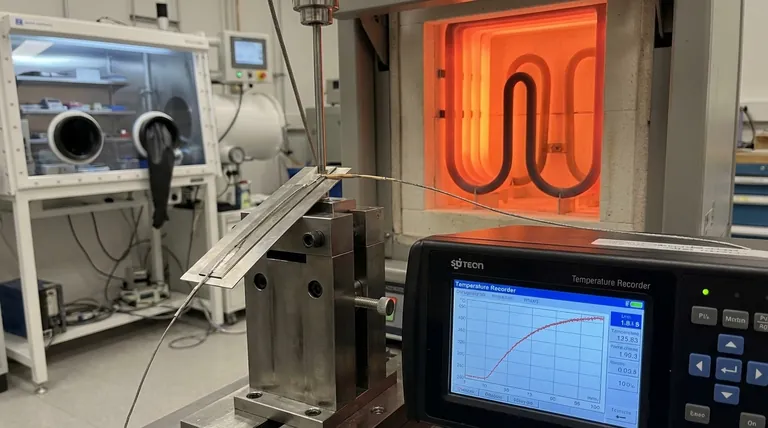

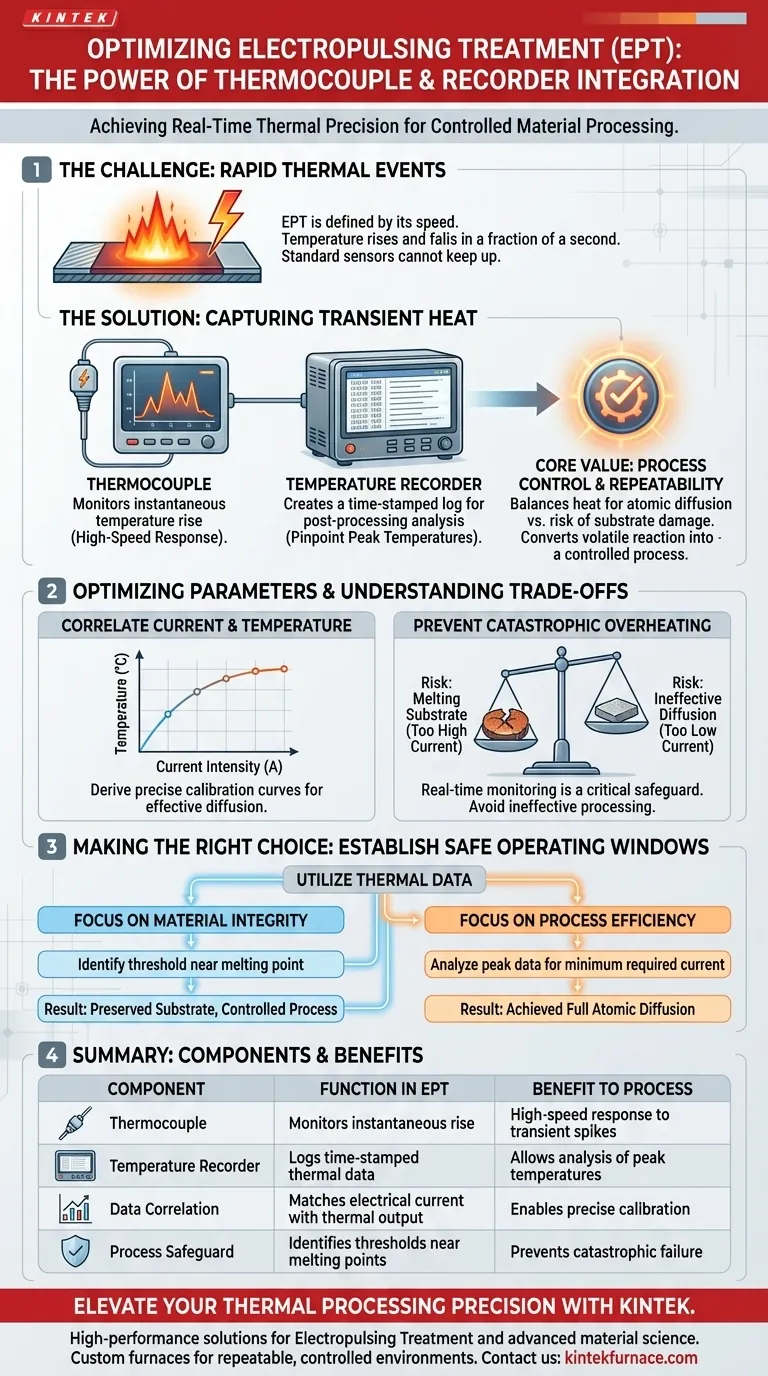

Real-time thermal precision is non-negotiable in rapid material processing. In Electropulsing Treatment (EPT), the combined use of a thermocouple and a temperature recorder is necessary to monitor the instantaneous temperature rise within composite strips. Because the treatment occurs over an extremely short duration, this specific instrumentation setup is the only way to accurately capture peak temperatures relative to the current applied.

The core value of this setup is process control: it provides the data needed to balance the heat required for atomic diffusion against the risk of destroying the substrate.

The Challenge of Rapid Thermal Processing

Capturing Transient Heat Spikes

Electropulsing Treatment is defined by its speed. The temperature within the material rises and falls in a fraction of a second. Standard thermal sensors often lack the response time to register these rapid changes accurately.

The Necessity of Recording

A simple readout is insufficient for EPT because the values change too quickly for human observation. The temperature recorder creates a time-stamped log of the thermal event. This allows researchers to pinpoint the exact peak temperature reached during the pulse.

Optimizing Process Parameters

Correlating Current and Temperature

To control EPT, operators must understand the relationship between electrical input and thermal output. By plotting temperature data against current intensity, you can derive a precise calibration curve for your specific composite strip.

Achieving Effective Diffusion

The primary goal of EPT is often to facilitate diffusion between material layers. This requires reaching a specific thermal threshold. The thermocouple feedback confirms that the process has generated enough heat to activate this material change.

Understanding the Trade-offs

Preventing Catastrophic Overheating

There is a fine line between treating the material and destroying it. If the current intensity is too high, the temperature may exceed the melting point of the copper substrate. Real-time monitoring acts as a critical safeguard to prevent structural failure.

Avoiding Ineffective Processing

Conversely, excessive caution can lead to underperformance. If the recorded temperatures are too low, the diffusion process will be insufficient. This results in a composite strip that lacks the desired mechanical or electrical properties.

Making the Right Choice for Your Goal

To utilize Electropulsing Treatment effectively, you must use your thermal data to establish safe operating windows.

- If your primary focus is material integrity: Use the recorder to identify the exact current threshold where the copper substrate begins to approach its melting point.

- If your primary focus is process efficiency: Analyze the peak temperature data to determine the minimum current intensity required to achieve full atomic diffusion.

Accurate measurement converts EPT from a volatile reaction into a controlled, repeatable engineering process.

Summary Table:

| Feature | Function in Electropulsing Treatment (EPT) | Benefit to Process |

|---|---|---|

| Thermocouple | Monitors instantaneous temperature rise in composite strips. | Provides high-speed response to transient heat spikes. |

| Temperature Recorder | Logs time-stamped thermal data during the pulse. | Allows analysis of peak temperatures post-processing. |

| Data Correlation | Matches electrical current intensity with thermal output. | Enables precise calibration for specific material types. |

| Process Safeguard | Identifies thresholds near material melting points. | Prevents catastrophic substrate failure or structural damage. |

Elevate Your Thermal Processing Precision with KINTEK

Don't let rapid thermal events compromise your material integrity. KINTEK provides high-performance laboratory solutions designed to meet the rigorous demands of Electropulsing Treatment and advanced material science. Backed by expert R&D and manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, all of which can be customized to your unique specifications.

Whether you are optimizing atomic diffusion or establishing safe operating windows for sensitive substrates, our high-temp furnaces ensure the repeatable, controlled environment your research requires.

Ready to achieve superior process control? Contact KINTEK today to discuss your custom furnace needs.

Visual Guide

References

- Zefeng Wang, Wangzhe Du. Effect of Electric Pulse Treatment on the Interfacial Properties of Copper/304 Stainless Steel Composite Thin Strips Fabricated by Roll Bonding. DOI: 10.3390/met15020112

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Stainless Steel Quick Release Vacuum Chain Three Section Clamp

People Also Ask

- What is the primary use of molybdenum disilicide? Ideal for High-Temp Heating Elements

- What are the two main element types used in ceramic infrared heaters? Choose the Best for Your Lab

- How are SC Type Silicon Carbide Heating Elements packaged and handled? Ensure Longevity and Avoid Damage

- What are the typical applications of molybdenum heating elements? Powering High-Temp Furnace Processes

- What are the temperature limitations for furnaces using molybdenum disilicide heating elements? Key Factors and Solutions Explained

- How can the power of a heating element be increased? Boost Heat Output Safely with Key Methods

- What are the technical advantages of micro-tubular ceramic heaters? Speed Up Your Rapid Thermal Cycling Tests

- What are the common types of ceramic heating elements? Find the Right Heater for Your Application