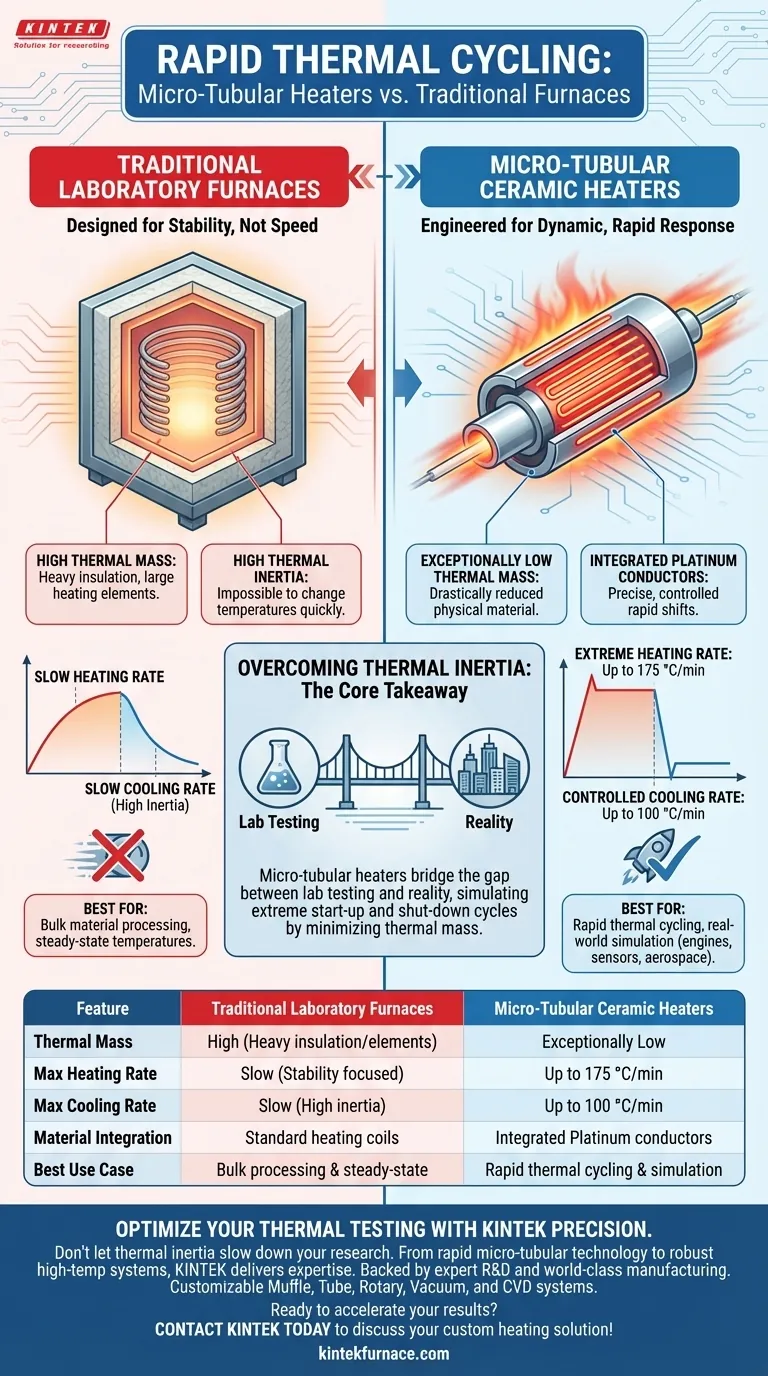

The primary technical advantage of micro-tubular ceramic heaters with integrated platinum conductors is their exceptionally low thermal mass. Unlike traditional furnaces, which are hindered by high thermal inertia, these specialized heaters can achieve rapid heating rates of up to 175 °C/min and cooling rates of up to 100 °C/min.

Core Takeaway: Traditional laboratory furnaces are designed for stability, not speed. By minimizing thermal mass, micro-tubular heaters bridge the gap between lab testing and reality, allowing you to accurately simulate the extreme start-up and shut-down cycles found in actual application environments.

Overcoming Thermal Inertia

The Problem with Traditional Furnaces

Standard laboratory furnaces typically rely on heavy insulation and large heating elements.

While this design provides excellent temperature stability, it creates high thermal inertia. This makes it physically impossible to change temperatures quickly, rendering them unsuitable for testing components that undergo rapid thermal shocks in the real world.

The Micro-Tubular Solution

Micro-tubular ceramic heaters address this by drastically reducing the physical material involved in the heating process.

The low thermal mass of the ceramic tube allows the system to respond almost instantly to power input changes. This creates a "rapid response" characteristic that is critical for dynamic testing.

Performance Metrics

Extreme Heating Rates

Because energy is not wasted heating massive amounts of insulation, these heaters can ramp up temperatures aggressively.

You can achieve heating rates as fast as 175 °C/min. This capability is essential for simulating rapid start-up sequences in combustion engines, sensors, or aerospace components.

Controlled Cooling Rates

Thermal cycling is not just about getting hot; it is about cooling down quickly to start the next cycle.

These devices allow for cooling rates up to 100 °C/min. This enables tight, repetitive cycling that stresses materials in a fraction of the time required by a standard furnace.

The Role of Integrated Platinum

The integration of platinum conductors is key to this performance.

Platinum provides the necessary electrical stability and resistance properties to handle these rapid shifts without degradation. This integration ensures that the extreme cycling is not only fast but also precise and controlled.

Understanding the Constraints

Sample Size Limitations

The term "micro-tubular" implies a specific physical constraint regarding the test zone.

While these heaters offer speed, they likely have a smaller effective working volume compared to cavernous laboratory furnaces. They are best suited for testing small components, sensors, or material coupons rather than large assemblies.

Application Specificity

These are specialized tools designed for dynamic environments.

If your testing requires holding a massive thermal load at a steady temperature for days with minimal fluctuation, the high inertia of a traditional furnace might actually be preferable to the agile response of a micro-heater.

Making the Right Choice for Your Goal

To select the correct equipment for your thermal testing, consider your primary objective:

- If your primary focus is real-world simulation: Choose the micro-tubular heater to replicate rapid start-up and shut-down conditions that traditional equipment cannot catch.

- If your primary focus is bulk material processing: Stick to traditional laboratory furnaces where high thermal inertia helps maintain steady-state temperatures over large volumes.

Select the tool that matches the dynamic nature of your application, not just the maximum temperature required.

Summary Table:

| Feature | Traditional Laboratory Furnaces | Micro-Tubular Ceramic Heaters |

|---|---|---|

| Thermal Mass | High (Heavy insulation/elements) | Exceptionally Low |

| Max Heating Rate | Slow (Stability focused) | Up to 175 °C/min |

| Max Cooling Rate | Slow (High inertia) | Up to 100 °C/min |

| Material Integration | Standard heating coils | Integrated Platinum conductors |

| Best Use Case | Bulk processing & steady-state | Rapid thermal cycling & simulation |

Optimize Your Thermal Testing with KINTEK Precision

Don't let thermal inertia slow down your research. Whether you need the rapid response of micro-tubular technology for dynamic simulations or the robust stability of traditional high-temp systems, KINTEK delivers the expertise you need.

Backed by expert R&D and world-class manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems. All our laboratory furnaces are fully customizable to meet your unique thermal processing requirements and sample specifications.

Ready to accelerate your thermal cycling results? Contact KINTEK today to discuss your custom heating solution!

Visual Guide

References

- Dhruba Panthi, Hai Feng. Extreme Thermal Cycling of Anode‐Supported Microtubular Solid Oxide Fuel Cells Using a Novel Test Setup. DOI: 10.1002/aesr.202500119

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

People Also Ask

- What are the main features of MoSi2 heating elements? Achieve Unmatched High-Temp Performance

- What is a heating element and its key components? Discover How It Powers Efficient Heat Generation

- What are the key requirements for a good ceramic heating element? Achieve Reliable, Efficient Heat for Your Lab

- What are the energy efficiency differences between ceramic and infrared heaters? Choose the Best Heater for Your Space

- What is the process by which a heating element converts electrical energy into heat? Discover Joule Heating Essentials

- What is the maximum operating temperature for Molybdenum Disilicide heating elements? Unlock High-Temp Performance Up to 1850°C

- How does staged combustion in double-P radiant tubes suppress NOx? Advanced Emission Control Solutions

- Are molybdenum disilicide heating elements customizable? Tailor High-Temp Solutions for Your Furnace