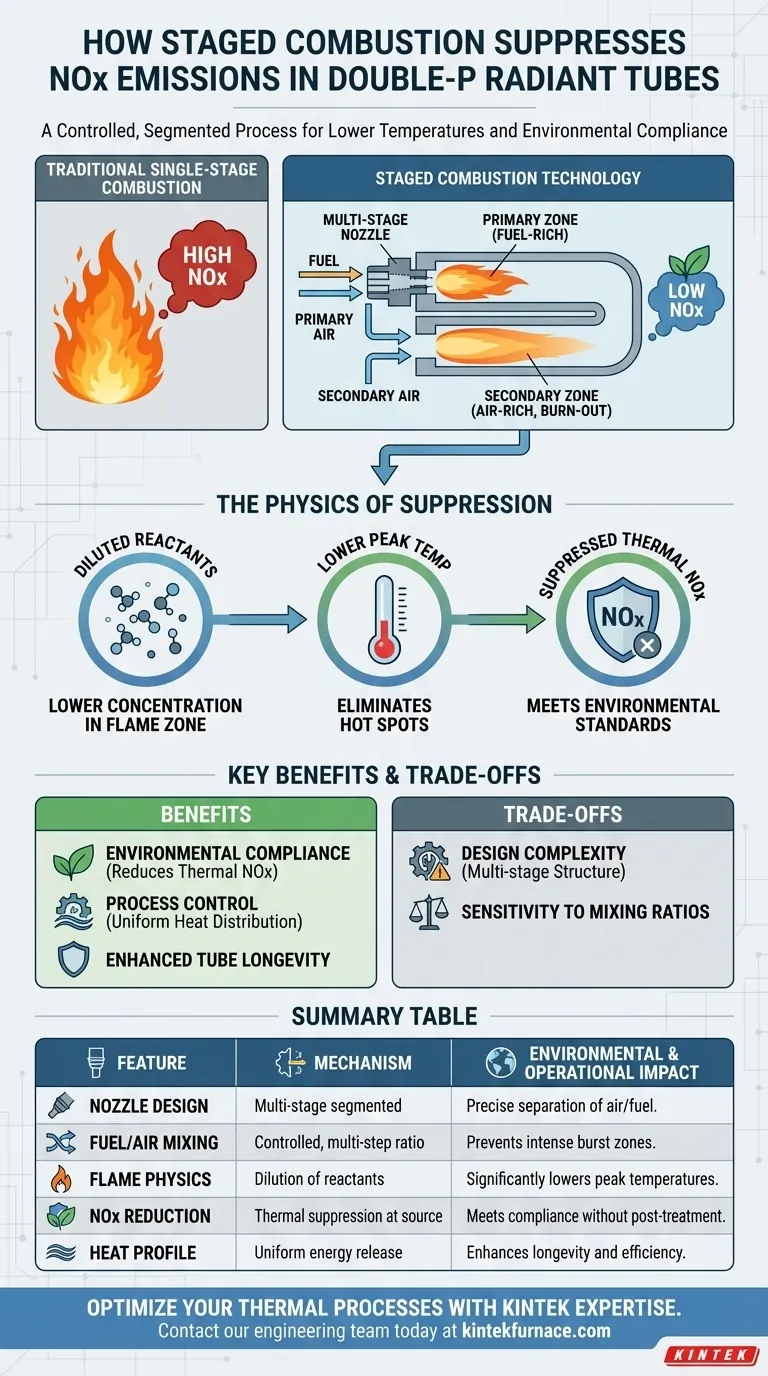

Staged combustion technology suppresses NOx emissions by implementing a controlled, segmented burning process within double-P radiant tubes. Instead of combusting fuel in a single, intense burst, this system utilizes a multi-stage nozzle to precisely manage the mixing ratios of fuel with both primary and secondary air.

By diluting the concentration of reactants in the flame zone, this technology lowers the maximum temperature at the flame's center, effectively removing the thermal conditions necessary for NOx formation.

The Mechanics of Segmented Combustion

To understand how this technology works, you must look at how it fundamentally changes the environment inside the radiant tube. It moves away from chaotic combustion toward a highly engineered, multi-step process.

The Multi-Stage Nozzle Structure

The heart of this system is the multi-stage nozzle. Unlike standard burners that mix air and fuel immediately, this component is designed to physically separate the introduction of combustion elements.

It allows for a segmented combustion process. This mechanical separation is critical for controlling exactly when and where the fuel interacts with the oxidizer.

Controlling Air and Fuel Ratios

The system distinguishes between primary and secondary air. By controlling the ratio of fuel mixed with these two distinct air streams, the burner dictates the pace of combustion.

This prevents the fuel from burning all at once. Instead, it creates a staged release of energy that is more manageable and thermally uniform.

The Physics of Suppression

The reduction of emissions is not a chemical filtration process, but a result of altering the physics of the flame itself.

Diluting Reactant Concentration

By staging the air entry, the system effectively dilutes the concentration of reactants in the critical flame zone.

When the concentration of fuel and oxygen is lower during the initial ignition phase, the combustion intensity is reduced. This prevents the immediate, violent reactions that characterize high-emission burners.

Lowering Peak Flame Temperatures

The primary driver of thermal NOx is heat. Specifically, it is the maximum temperature at the center of the flame that causes atmospheric nitrogen to oxidize.

Staged combustion mechanically lowers this peak temperature. by spreading the heat release over a larger area (or time), the system eliminates the "hot spots" responsible for the majority of NOx generation.

Understanding the Trade-offs

While staged combustion provides significant environmental benefits, it introduces specific engineering considerations that must be managed.

Complexity of Design

The reliance on a multi-stage nozzle structure implies a higher degree of mechanical complexity compared to single-stage burners. The hardware must be precisely engineered to maintain the correct separation of primary and secondary air.

Sensitivity to Mixing Ratios

The system's effectiveness relies entirely on the precise control of mixing ratios. If the balance between fuel, primary air, and secondary air drifts, the benefits of reactant dilution and temperature suppression can be lost.

Making the Right Choice for Your Goal

To determine if this technology aligns with your operational requirements, consider your specific constraints regarding emissions and thermal profile.

- If your primary focus is Environmental Compliance: This technology is ideal as it mechanically inhibits thermal NOx at the source, reducing the need for post-combustion treatment.

- If your primary focus is Process Control: The ability to lower peak flame temperatures offers a way to manage heat distribution more evenly within the radiant tube, protecting equipment longevity.

Staged combustion transforms the burner from a simple heat source into a precision instrument that manages flame chemistry to minimize environmental impact.

Summary Table:

| Feature | Staged Combustion Mechanism | Environmental & Operational Impact |

|---|---|---|

| Nozzle Design | Multi-stage segmented nozzle | Enables precise separation of primary and secondary air |

| Fuel/Air Mixing | Controlled, multi-step ratio management | Prevents intense, single-burst combustion zones |

| Flame Physics | Dilution of reactants in flame zone | Significantly lowers peak center temperatures |

| NOx Reduction | Thermal suppression at the source | Meets strict environmental compliance without post-treatment |

| Heat Profile | Uniform energy release | Enhances radiant tube longevity and thermal efficiency |

Optimize Your Thermal Processes with KINTEK Expertise

Are you looking to reduce emissions while maintaining peak thermal performance? Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, along with customizable lab high-temp furnaces tailored to your unique specifications. Our advanced heating technologies ensure you meet environmental standards without sacrificing process control.

Ready to upgrade your lab or industrial furnace? Contact our engineering team today to discuss how our precision-engineered systems can enhance your operational efficiency.

Visual Guide

References

- Chien-Cheng Lin, Chien-Hsiung Tsai. Simulation of Staged Combustion Function in Double P-Type Radiant Tubes. DOI: 10.3390/engproc2025092094

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What are the primary functions of a tantalum (Ta) tube in the synthesis of KBaBi? Essential Corrosion Resistance

- What is the process by which a heating element converts electrical energy into heat? Discover Joule Heating Essentials

- What are the advantages of ceramic heating elements over metal ones? Superior Durability, Efficiency & Safety

- Why is a high-precision thermocouple probe used during the temperature calibration of fiber optic sensors? Guide

- How does the resistivity of silicon carbide change with temperature? Discover SiC's Self-Regulating Heating Properties

- What parameters does the IEC standard specify for heating elements? Ensure Safety and Performance

- What is the temperature range where MoSi2 heating elements should not be used for long periods? Avoid 400-700°C to Prevent Failure

- In which industrial applications are MoSi2 heating elements typically preferred? Ideal for High-Temp Glass, Ceramics, and Metallurgy