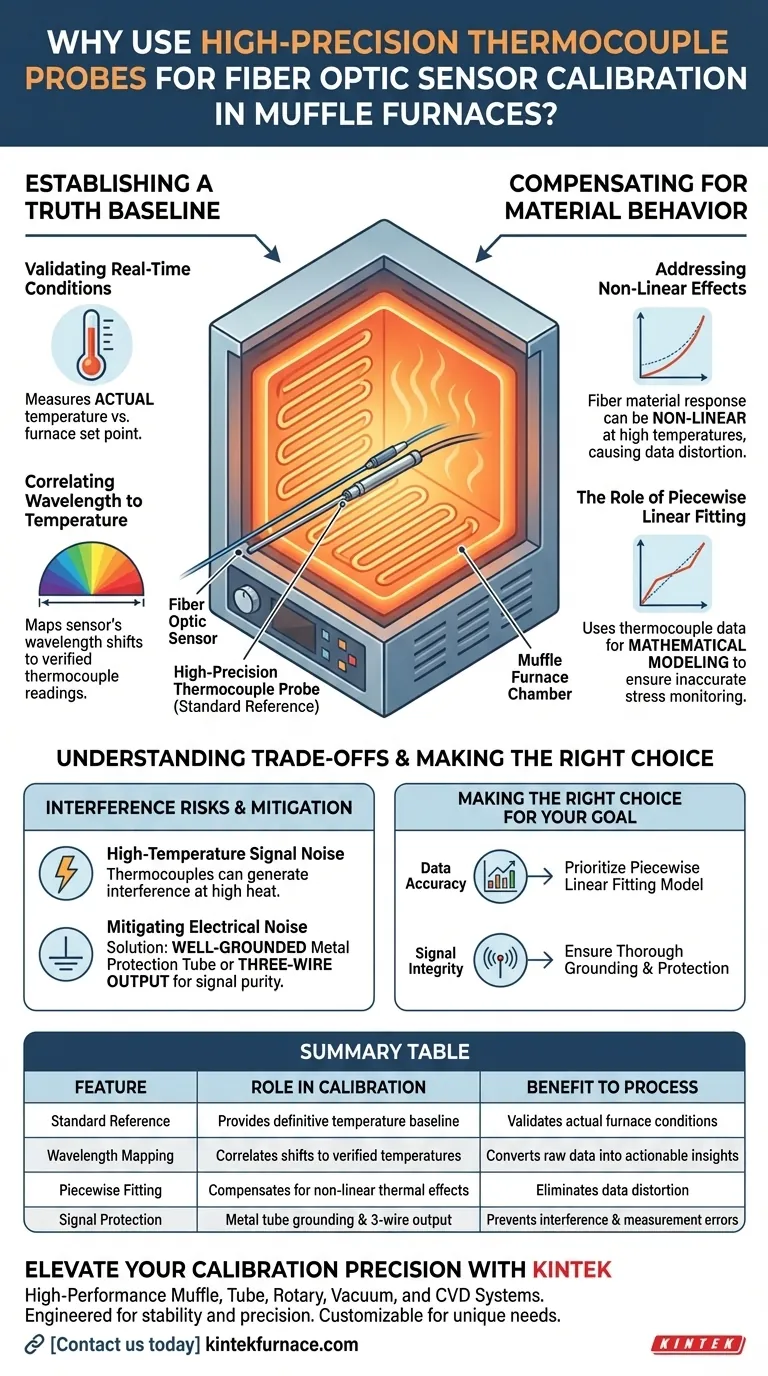

A high-precision thermocouple probe serves as the definitive standard temperature reference during the calibration process. It is placed in close proximity to the fiber optic sensor to validate the actual internal temperature of the muffle furnace in real-time, providing a baseline of truth against which the optical sensor's performance is measured.

By comparing the thermocouple’s stable readings with the fiber optic sensor's wavelength shifts, researchers can generate a piecewise linear fitting. This mathematical model compensates for non-linear thermal effects within the fiber material, ensuring that future stress monitoring data is not distorted by high-temperature anomalies.

Establishing a Truth Baseline

Validating Real-Time Conditions

The environment inside a muffle furnace can fluctuate. To ensure the fiber optic sensor is calibrated correctly, you cannot rely solely on the furnace's set point.

You must use a high-precision thermocouple as a standard reference.

Placed near the fiber optic sensor, this probe measures the actual temperature the sensor is experiencing.

Correlating Wavelength to Temperature

Fiber optic sensors respond to heat by exhibiting wavelength shifts.

To interpret these shifts accurately, they must be mapped against a known, verified temperature value provided by the thermocouple.

Compensating for Material Behavior

Addressing Non-Linear Effects

Fiber optic materials do not always respond to temperature changes in a perfectly linear fashion, especially at high temperatures.

Thermal effects can introduce non-linear distortions in the data, which would skew stress monitoring results if left uncorrected.

The Role of Piecewise Linear Fitting

Using the data from the thermocouple, researchers can apply piecewise linear fitting.

This method breaks the temperature response into smaller sections to model the non-linearity accurately.

This mathematical compensation ensures that the fiber optic sensor provides accurate stress monitoring data, effectively filtering out thermal errors.

Understanding the Trade-offs: Interference Risks

High-Temperature Signal Noise

While thermocouples are essential for calibration, they are not immune to environmental challenges.

At higher furnace temperatures, thermocouples connected to controllers can generate interference and measurement errors.

Mitigating Electrical Noise

To maintain the integrity of your calibration standard, the thermocouple's metal protection tube must be well-grounded.

Failure to ground the device properly can result in signal noise that compromises the calibration.

In critical scenarios, utilizing a three-wire output thermocouple is recommended to further reduce interference and ensure the reference data remains pure.

Making the Right Choice for Your Goal

To ensure your calibration process yields reliable stress monitoring data, apply the following principles:

- If your primary focus is data accuracy: Prioritize the creation of a piecewise linear fitting model to mathematically compensate for the fiber's non-linear thermal response.

- If your primary focus is signal integrity: Ensure the thermocouple utilizes a metal protection tube that is thoroughly grounded to prevent high-temperature electrical interference.

By anchoring your optical data to a precise thermal reference, you transform raw wavelength shifts into actionable, verified engineering insights.

Summary Table:

| Feature | Role in Calibration | Benefit to Process |

|---|---|---|

| Standard Reference | Provides a definitive temperature baseline | Validates actual furnace conditions vs. set points |

| Wavelength Mapping | Correlates shifts to verified temperatures | Converts raw optical data into actionable insights |

| Piecewise Fitting | Compensates for non-linear thermal effects | Eliminates data distortion at high temperatures |

| Signal Protection | Metal tube grounding and 3-wire output | Prevents electrical interference and measurement errors |

Elevate Your Calibration Precision with KINTEK

Don't let thermal non-linearity or signal noise compromise your critical research. KINTEK provides high-performance high-temperature solutions—including Muffle, Tube, Rotary, Vacuum, and CVD systems—engineered for stability and precision.

Backed by expert R&D and manufacturing, our lab furnaces are fully customizable to meet your unique calibration and stress monitoring needs. Contact us today to discover how KINTEK's advanced thermal technology can provide the accuracy and reliability your lab demands.

Visual Guide

References

- Kaiyue Qi, Peng Li. Monitoring of Internal Stress in Stainless Steel Materials at High Temperatures Using Optical FPI and LPFG. DOI: 10.58286/30974

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is 'pest oxidation' in MoSi2 elements? Avoid Costly Furnace Contamination

- In what applications are silicon carbide heating rods commonly used? Essential for High-Temp Metallurgy, Ceramics & More

- What are the two types of silicon carbide heating elements described? Compare One-Piece vs. Three-Piece for Your Lab

- What are the safety advantages of ceramic heating elements over electric heating wires? Discover Inherent Electrical and Fire Safety

- What are the typical applications of molybdenum heating elements? Powering High-Temp Furnace Processes

- What are the advantages of quartz tubes in terms of durability and maintenance? Enhance Lab Efficiency with Low-Maintenance Solutions

- What makes ceramic heating elements more energy-efficient than metal alternatives? Superior Insulation & Uniform Heat Distribution

- How do silicon carbide heating elements work? Achieve High-Temp Precision & Efficiency