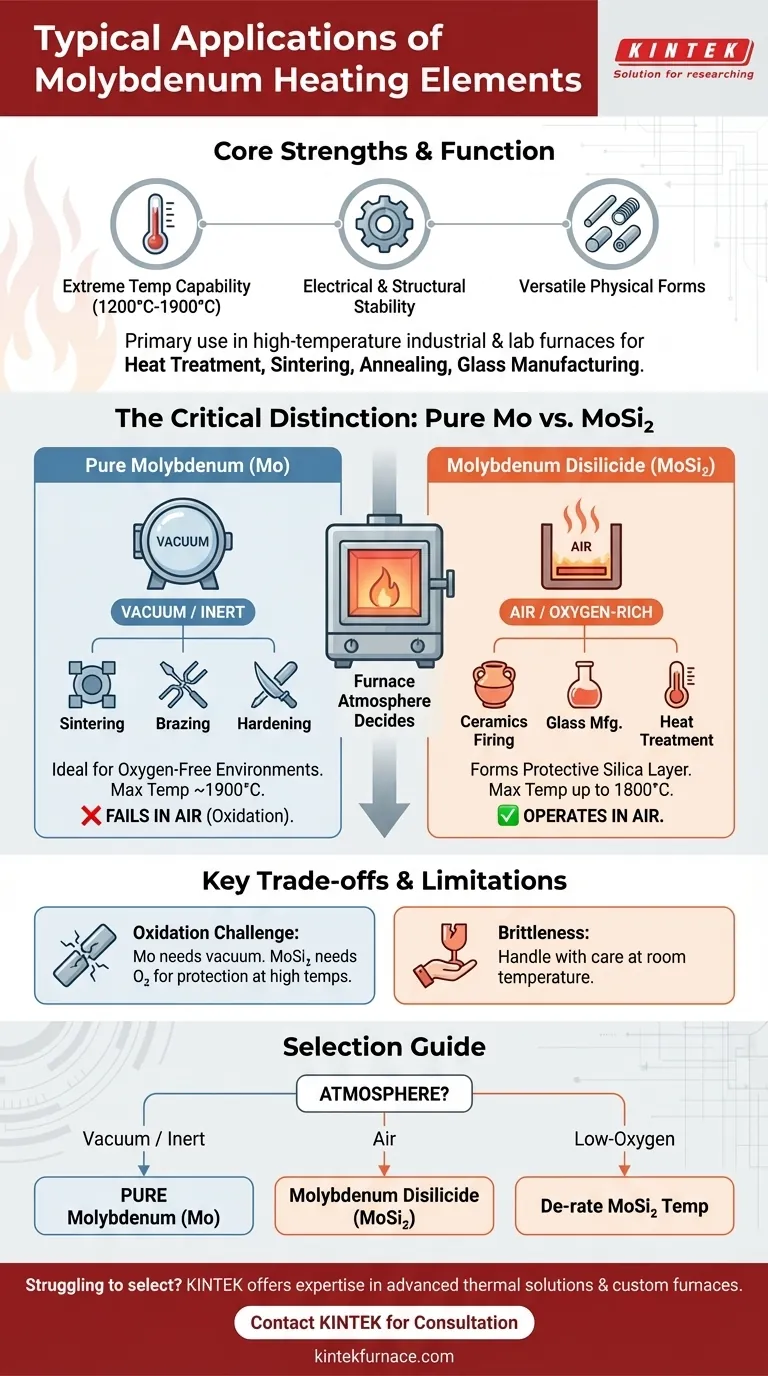

In short, molybdenum heating elements are primarily used in high-temperature industrial and laboratory furnaces for processes like heat treatment, sintering, annealing, and glass manufacturing. They are chosen for their ability to operate reliably at temperatures where common heating alloys like nickel-chromium would fail, typically in the range of 1200°C to 1900°C.

The core decision to use a molybdenum heating element is driven by the need for extreme heat stability. However, the choice between pure molybdenum (Mo) and molybdenum disilicide (MoSi₂) is dictated entirely by the furnace's operating atmosphere, specifically the presence of oxygen.

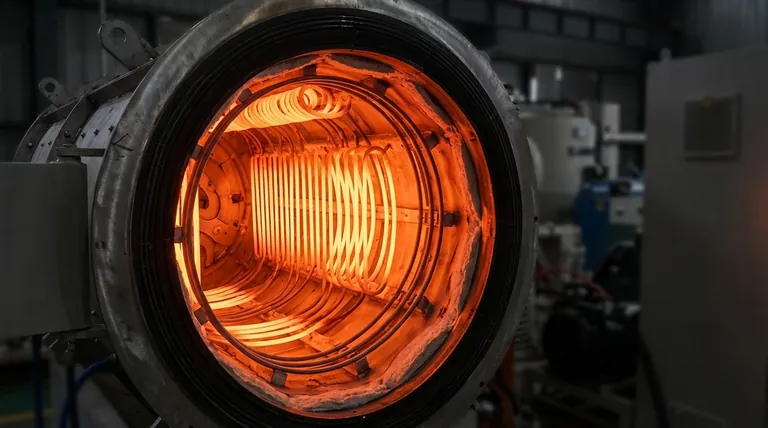

The Core Strengths of Molybdenum Heaters

Molybdenum's properties make it a foundational material for high-temperature industrial processes. Understanding these strengths clarifies why it is selected over other materials.

Extreme Temperature Capability

Molybdenum is a refractory metal with an exceptionally high melting point of 2623°C (4753°F). This allows pure molybdenum elements to achieve peak operating temperatures around 1900°C in controlled environments.

Molybdenum disilicide (MoSi₂) variants can operate reliably in air at temperatures up to 1800°C (3272°F), far exceeding the limits of standard metallic heating elements.

Electrical and Structural Stability

Molybdenum and its compounds maintain excellent structural stability and stable electrical resistance under extreme heat. This ensures consistent, predictable heating performance over long operational lifetimes.

Unlike some materials, MoSi₂ elements do not age when operated at high power, meaning their resistance does not change significantly over time, simplifying power control.

Versatile Physical Forms

These heating elements are manufactured in various configurations to fit different furnace designs. They are commonly available as wires, rods, strips, and custom-formed tubes, providing flexibility for equipment designers.

The Critical Distinction: Pure Mo vs. MoSi₂

The most important factor in selecting a molybdenum heater is understanding the difference between its pure form and its disilicide compound. This choice is non-negotiable and depends on the furnace atmosphere.

Pure Molybdenum (Mo): For Vacuum or Inert Atmospheres

Pure molybdenum elements are the standard for high-temperature vacuum furnaces. Their high melting point and strength are ideal for processes like hardening, brazing, and sintering metals where an oxygen-free environment is required.

The primary limitation of pure molybdenum is its severe susceptibility to oxidation at high temperatures, which makes it unsuitable for use in air.

Molybdenum Disilicide (MoSi₂): For High Heat in Open Air

Molybdenum disilicide (MoSi₂) elements are engineered specifically for high-temperature operation in the presence of oxygen. They form a protective silica (SiO₂) layer on their surface that prevents further oxidation.

This unique property makes them the preferred choice for a wide range of industrial applications, including ceramics firing, glass manufacturing, and heat treatment in electric furnaces that operate in air.

Understanding the Trade-offs and Limitations

While powerful, molybdenum heating elements have specific constraints that must be respected for successful and safe operation.

The Oxidation Challenge

As noted, pure molybdenum oxidizes rapidly and catastrophically in air at high temperatures. It absolutely must be used in a vacuum or a protective, inert gas atmosphere.

For MoSi₂ elements, their maximum operating temperature must be lowered in low-oxygen atmospheres. The protective silica layer cannot form properly without sufficient oxygen, leading to element degradation.

Brittleness and Handling

Molybdenum can be brittle at room temperature, requiring careful handling during installation and maintenance to prevent cracking or breakage.

Making the Right Choice for Your Application

Your furnace's operating environment is the single most important factor when selecting a molybdenum heating element.

- If your primary focus is high-temperature processing in a vacuum or inert gas: Pure molybdenum (Mo) elements are the industry standard for their stability and heat capability.

- If your primary focus is high-temperature processing in an air atmosphere: Molybdenum disilicide (MoSi₂) elements are the correct choice due to their superior oxidation resistance.

- If you are working in a specialized, low-oxygen atmosphere: You must consult manufacturer specifications to de-rate the maximum operating temperature of MoSi₂ elements accordingly.

Choosing the correct molybdenum variant for your specific atmosphere is the key to achieving reliable, long-lasting high-temperature performance.

Summary Table:

| Application | Recommended Element Type | Key Atmosphere Requirement |

|---|---|---|

| Vacuum Furnaces (Brazing, Sintering) | Pure Molybdenum (Mo) | Vacuum or Inert Gas |

| High-Temp Processing in Air (Ceramics, Glass) | Molybdenum Disilicide (MoSi₂) | Oxygen-Rich (Air) |

| Heat Treatment & Annealing | Depends on Furnace Type | Dictates Mo vs. MoSi₂ Choice |

Struggling to select the right heating element for your high-temperature furnace?

KINTEK's expertise in advanced thermal solutions is your key to success. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with robust high-temperature furnace systems. Our product line, including Muffle, Tube, and Vacuum & Atmosphere Furnaces, is complemented by strong deep customization capabilities to precisely meet your unique experimental requirements—whether you need the vacuum stability of pure Molybdenum or the oxidative resilience of MoSi₂.

Let our engineers help you achieve reliable, long-lasting performance. Contact KINTEL today for a personalized consultation!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- How does the ultra-low oxygen environment of vacuum sintering affect titanium composites? Unlock Advanced Phase Control

- Why is a high-vacuum environment necessary for sintering Cu/Ti3SiC2/C/MWCNTs composites? Achieve Material Purity

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- What is the purpose of setting a mid-temperature dwell stage? Eliminate Defects in Vacuum Sintering

- What tasks does a high-temperature vacuum sintering furnace perform for PEM magnets? Achieve Peak Density