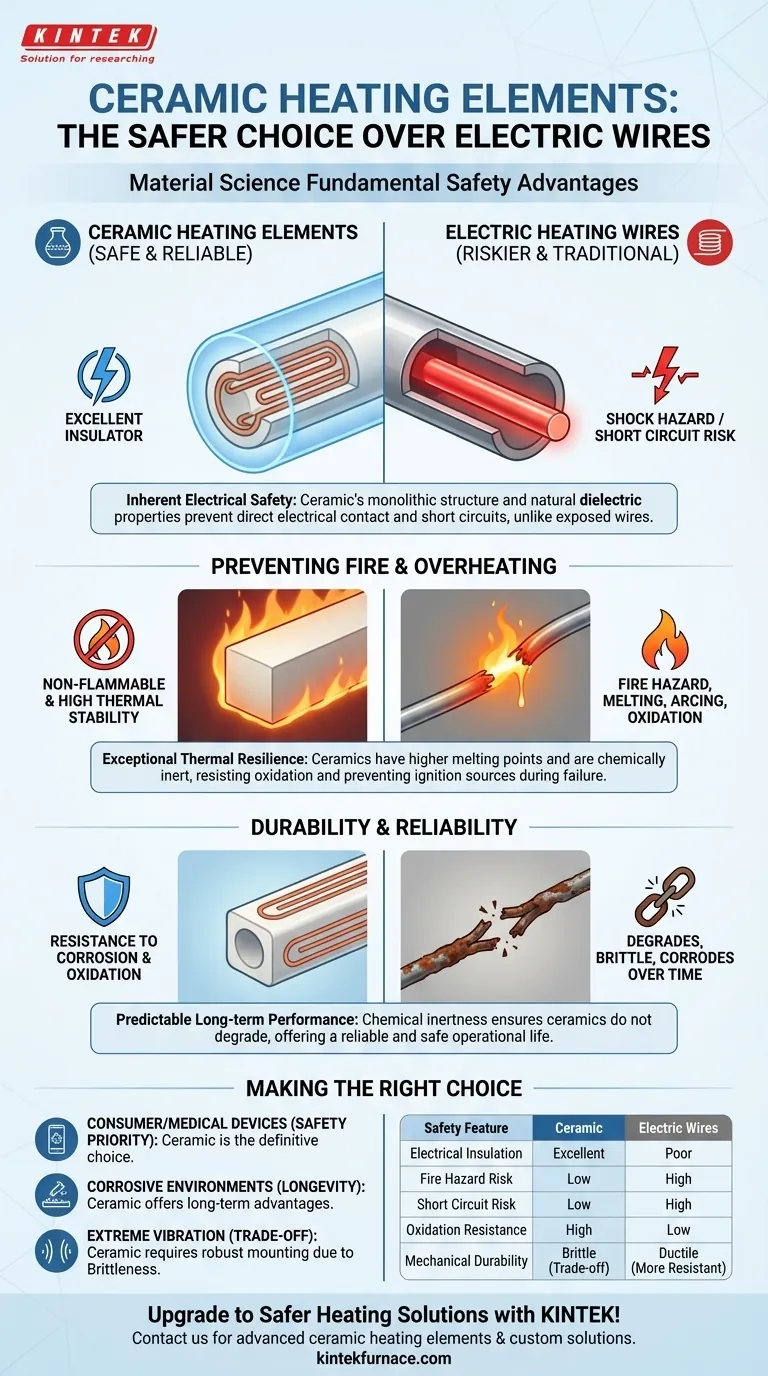

From a material science standpoint, the safety advantages of ceramic heating elements are not added features, but fundamental properties of the material itself. Unlike traditional electric heating wires, ceramics are excellent electrical insulators, which drastically reduces the risk of electric shock and short circuits. Their inherent non-flammable nature and high-temperature stability also provide superior protection against fire hazards.

The core safety advantage of ceramic heaters stems directly from their material composition. They physically isolate the electrical current from the environment while being far more resistant to the high-temperature degradation and oxidation that cause traditional metal elements to fail dangerously.

The Principle of Inherent Electrical Safety

The most significant safety distinction lies in how each element type manages electricity. This is not a design choice but a fundamental difference in physics.

Superior Electrical Insulation

Traditional heating elements often use a bare metallic wire (like Nichrome) that is electrically live. Any breakdown in secondary insulation creates a direct path for current, posing a significant shock hazard.

Ceramic heaters, by contrast, are made from a material that is a natural electrical insulator (a dielectric). The heating element is safely encased within this non-conductive body, meaning the outer surface is not electrically active.

Mitigating Short Circuit Risk

In a metallic wire element, physical damage, corrosion, or vibration can cause the wire to break or shift, creating a short circuit against its own housing or other components. This is a primary cause of electrical fires.

The monolithic structure of a ceramic heater means the internal heating traces are protected. Even if the ceramic body sustains minor cracks, the risk of a dangerous short circuit is significantly lower than with an exposed or thinly sheathed wire.

Preventing Overheating and Fire Hazards

Beyond electrical risk, the material's response to high heat is a critical safety factor. Ceramics excel under thermal stress where metals begin to fail.

Exceptional Thermal Stability

Ceramic materials have much higher melting points than the alloys used in wire-wound heaters. They are fundamentally non-flammable and will not combust, even in catastrophic failure scenarios.

This high-temperature resilience prevents the element itself from becoming a source of ignition. Metal wires, when they fail, can melt, arc, and eject hot material.

Resistance to Oxidation and Corrosion

At high temperatures, metal wires react with oxygen in the air (oxidation). This process degrades the wire, making it brittle and increasing its electrical resistance, which can lead to hot spots and eventual failure.

Ceramics are chemically inert and highly resistant to oxidation and corrosion. This means they do not degrade over time in the same way, leading to a more predictable, reliable, and safer operational life.

Understanding the Trade-offs

No technology is without its limitations. Acknowledging the trade-offs is critical for proper engineering and application.

Brittleness and Mechanical Shock

The primary disadvantage of ceramics is their brittleness. Unlike ductile metals that can bend, ceramics can fracture or shatter if subjected to significant physical impact or vibration. Proper mounting and housing are essential to mitigate this risk.

Thermal Shock Potential

While highly resistant to sustained heat, some ceramic formulations can be susceptible to thermal shock—cracking caused by extremely rapid temperature changes. Modern ceramic heaters, particularly PTC (Positive Temperature Coefficient) types, are engineered to be highly resilient to this, but it remains a design consideration.

Making the Right Choice for Your Application

Selecting the appropriate heating technology requires aligning its properties with your primary goal.

- If your primary focus is maximum safety in consumer or medical devices: Ceramic is the definitive choice due to its inherent electrical insulation and fire resistance.

- If your primary focus is longevity in a corrosive or high-humidity environment: The chemical inertness of ceramic provides a significant long-term safety and reliability advantage over metals that will corrode.

- If your primary focus is an application with extreme vibration or physical impact risk: You must either engineer a robust mounting solution for a ceramic element or consider a heavily sheathed metallic element as a more durable alternative.

Ultimately, choosing a heating element based on its fundamental material properties is the most effective way to engineer a safe and reliable system.

Summary Table:

| Safety Feature | Ceramic Heating Elements | Electric Heating Wires |

|---|---|---|

| Electrical Insulation | Excellent (natural insulator) | Poor (requires secondary insulation) |

| Fire Hazard Risk | Low (non-flammable, high thermal stability) | High (can melt, arc, or combust) |

| Short Circuit Risk | Low (monolithic structure) | High (prone to damage and shorting) |

| Oxidation Resistance | High (chemically inert) | Low (degrades over time) |

| Mechanical Durability | Brittle (susceptible to impact) | Ductile (more resistant to shock) |

Upgrade to safer heating solutions with KINTEK! Leveraging exceptional R&D and in-house manufacturing, we provide advanced ceramic heating elements and a full product line including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure precise solutions for your unique experimental needs, enhancing safety and reliability in your lab. Contact us today to discuss how we can support your application!

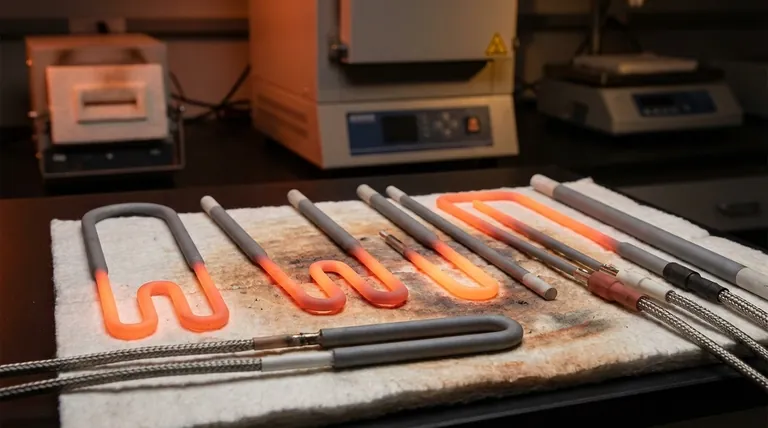

Visual Guide

Related Products

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- What are the advantages of using molybdenum-disilicide heating elements for aluminum alloy processing? (Rapid Heating Guide)

- What is the temperature range for MoSi2 heating elements? Maximize Lifespan in High-Temp Applications

- How can high temperature heating elements be customized for different applications? Tailor Elements for Peak Performance

- What role do MoSi2 heating elements play in 1500 °C experiments? Key to Stability and Precision

- What is the temperature range where MoSi2 heating elements should not be used for long periods? Avoid 400-700°C to Prevent Failure