In environments where extreme heat and reliability are non-negotiable, Molybdenum Disilicide (MoSi2) heating elements are the definitive choice. These elements are primarily selected for industrial applications requiring sustained, high temperatures—often between 1600°C and 1900°C—where furnace downtime is exceptionally costly. Key sectors include the manufacturing of glass, ceramics, and semiconductors; metallurgy and steel-making; and the production of high-strength materials for the aerospace and automotive industries.

The decision to use Molybdenum Disilicide (MoSi2) elements is driven by a need for exceptional thermal performance and long-term reliability at temperatures where most other materials would fail. Their unique ability to form a protective silica layer makes them ideal for processes where furnace uptime and consistent quality are paramount.

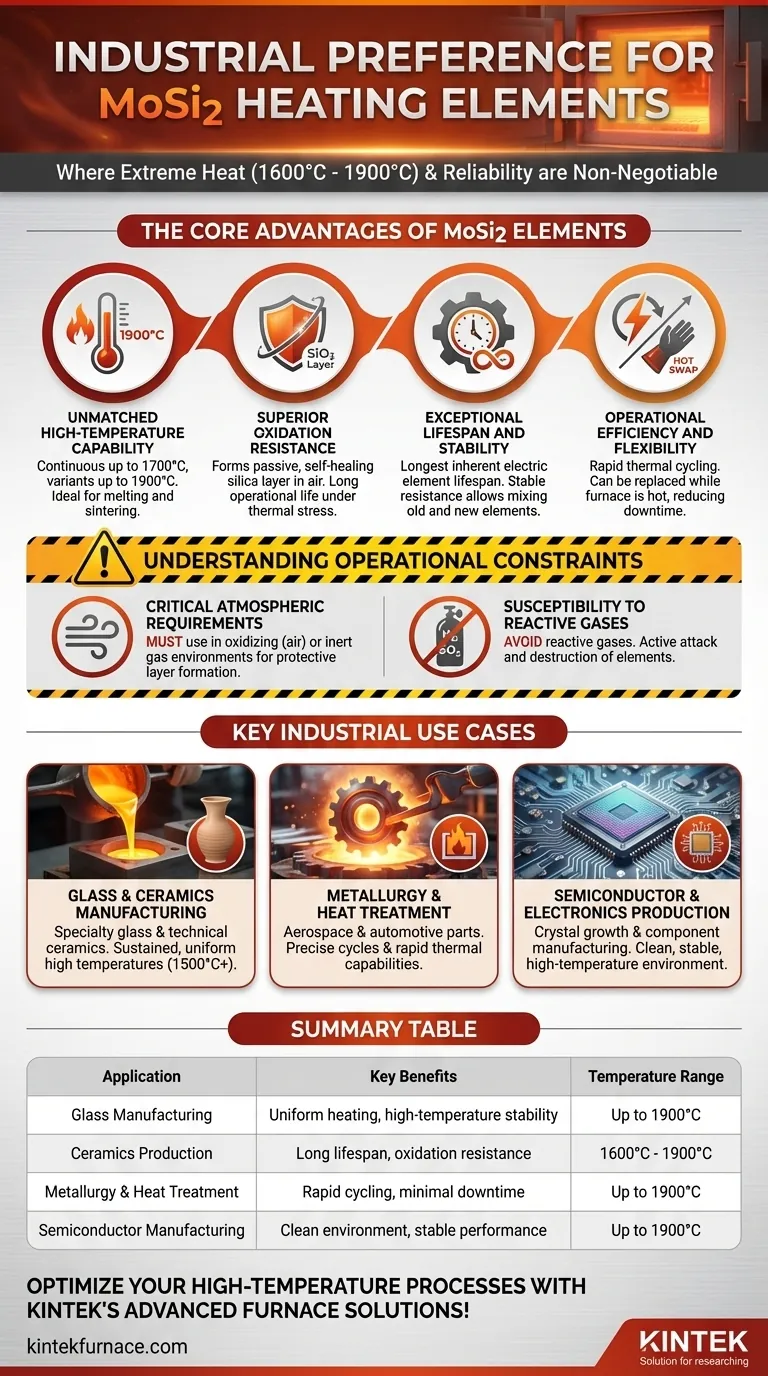

The Core Advantages of MoSi2 Elements

To understand why MoSi2 elements are preferred, it is essential to look beyond the applications and analyze their fundamental material properties. Their dominance in high-temperature settings is not accidental but a direct result of their unique characteristics.

Unmatched High-Temperature Capability

MoSi2 elements can operate continuously at temperatures up to 1700°C, with some specialized variants reaching as high as 1900°C. This is significantly higher than most metallic or silicon carbide heating elements.

This capability makes them indispensable for melting glass, sintering advanced ceramics, and performing heat treatments on high-strength metal alloys.

Superior Oxidation Resistance

At high temperatures, MoSi2 reacts with oxygen in the air to form a thin, non-porous layer of silica (SiO2) on its surface.

This passive, self-healing layer protects the underlying material from further oxidation and degradation, ensuring a remarkably long operational life even under extreme thermal stress.

Exceptional Lifespan and Stability

Due to their robust oxidation resistance, MoSi2 elements have the longest inherent lifespan of all common electric heating elements.

Their electrical resistance remains stable over time, which allows new elements to be connected in series with older ones without causing imbalances. This simplifies maintenance and reduces replacement costs.

Operational Efficiency and Flexibility

MoSi2 elements can handle rapid thermal cycling without risk of damage, allowing for faster furnace heat-up and cool-down times.

Crucially, they can be replaced while a furnace is still hot, which dramatically reduces costly downtime in continuous production environments.

Understanding the Operational Constraints

While powerful, MoSi2 elements are not a universal solution. Their performance is dependent on specific operating conditions, and failure to meet these requirements will lead to rapid failure.

Critical Atmospheric Requirements

MoSi2 elements are designed to be used in oxidizing (air) or inert gas environments. The presence of oxygen is necessary to form and maintain the protective silica layer.

Using them in a reducing atmosphere at high temperatures will prevent this layer from forming, leaving the element vulnerable.

Susceptibility to Reactive Gases

Certain gases will actively attack and destroy MoSi2 elements. These include hydrogen (H2), chlorine (Cl2), and sulfur dioxide (SO2).

If your industrial process involves these or other reactive gases, you must select an alternative heating element, as MoSi2 will not be viable.

Key Industrial Use Cases

The properties of MoSi2 directly align with the demands of several key industries.

Glass and Ceramics Manufacturing

The production of specialty glass and the sintering of technical ceramics require sustained, uniform temperatures often exceeding 1500°C. MoSi2 provides the necessary heat and stability for these demanding processes.

Metallurgy and Heat Treatment

Manufacturing high-strength parts for the aerospace and automotive sectors involves precise heat treatment cycles. MoSi2's ability to reach high temperatures and cycle quickly makes it ideal for creating materials with specific metallurgical properties.

Semiconductor and Electronics Production

Processes like crystal growth and the manufacturing of certain electronic components demand a clean, stable, high-temperature environment. MoSi2 elements provide this without introducing contaminants often associated with other heating methods.

Making the Right Choice for Your Process

Your decision should be guided by the specific technical requirements of your furnace and process.

- If your primary focus is reaching extreme process temperatures (1600°C+): MoSi2 is the default choice due to its superior thermal range and stability.

- If your primary focus is minimizing furnace downtime and maintenance: The long lifespan, stable resistance, and hot-swappable nature of MoSi2 elements make them highly cost-effective over time.

- If your process involves a reactive gas atmosphere (e.g., hydrogen): You must avoid MoSi2 elements and seek alternatives, as they will be chemically attacked and fail.

By understanding both its unparalleled strengths and its specific limitations, you can confidently determine if MoSi2 is the optimal solution for your high-temperature application.

Summary Table:

| Application | Key Benefits | Temperature Range |

|---|---|---|

| Glass Manufacturing | Uniform heating, high-temperature stability | Up to 1900°C |

| Ceramics Production | Long lifespan, oxidation resistance | 1600°C - 1900°C |

| Metallurgy & Heat Treatment | Rapid cycling, minimal downtime | Up to 1900°C |

| Semiconductor Manufacturing | Clean environment, stable performance | Up to 1900°C |

Optimize your high-temperature processes with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable MoSi2 heating elements and custom high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems. Our deep customization capabilities ensure precise alignment with your unique experimental needs, enhancing efficiency and reducing downtime. Contact us today to discuss how we can elevate your industrial applications!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What is the maximum temperature silicon carbide heating elements can withstand? Key Factors for Longevity and Performance

- What makes silicon carbide heating elements resistant to chemical corrosion? Discover the Protective Oxide Layer

- Why are silicon carbide heating elements essential in high-temperature industries? Unlock Reliable, Extreme Heat Solutions

- What are the properties and capabilities of Silicon Carbide (SiC) as a heating element? Unlock Extreme Heat and Durability

- Why are SIC heating elements resistant to chemical corrosion? Discover the Self-Protecting Mechanism