In short, the electrical resistivity of silicon carbide (SiC) decreases significantly as its temperature increases, especially from room temperature up to about 900°C. This relationship is non-linear and is the key property that allows SiC heating elements to heat up rapidly and then maintain a stable temperature without complex external controls.

Unlike a simple metal wire that increases its resistance when hot, silicon carbide behaves like a semiconductor. Its resistance drops as it heats up, allowing it to draw more power for rapid heating, and then stabilizes at high temperatures to prevent overheating and maintain a consistent output.

The Physics Behind SiC's Resistivity Change

To understand why silicon carbide behaves this way, you must first recognize that it is not a metal, but a semiconductor. This distinction is the root of its unique electrical properties.

SiC as a Semiconductor

Metals conduct electricity easily because they have a sea of free electrons ready to move. Semiconductors, like SiC, have their electrons more tightly bound. At room temperature, very few electrons are free to move, making the material a poor conductor with high resistivity.

The Role of Thermal Energy

As SiC is heated, the thermal energy excites the material's atomic lattice. This energy is sufficient to break electrons free from their bonds, creating mobile charge carriers (electrons and holes).

The Result: A Negative Temperature Coefficient

More free charge carriers means the material can conduct electricity more easily. Therefore, as the temperature of silicon carbide goes up, its electrical resistivity goes down. This is known as a negative temperature coefficient (NTC) of resistivity, the direct opposite of most metals.

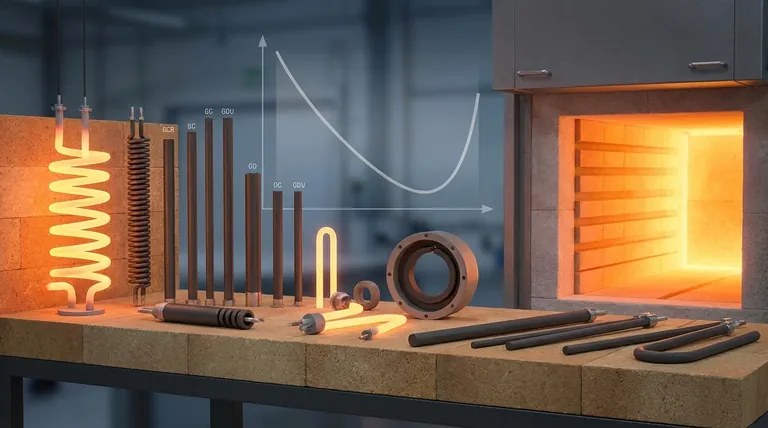

Visualizing the Resistivity-Temperature Curve

The term "non-linear" from the references describes a specific and very useful curve. For most SiC heating elements, the resistivity follows a characteristic "U" shape when plotted against temperature.

The Characteristic "U-Shaped" Curve

At room temperature, the resistivity of SiC is very high. As it heats up, the resistivity drops sharply and dramatically, reaching its lowest point somewhere between 800°C and 1000°C. Beyond this point, as the temperature climbs even higher (e.g., to 1500°C), other scattering effects begin to dominate, and the resistivity starts to slowly increase again.

How This Enables "Self-Regulation"

This curve is the key to SiC's utility as a heating element.

- Rapid Heat-Up: The high initial resistance drops quickly, causing the element to draw progressively more current and power (P = V²/R), leading to very fast heating.

- Stable Operation: As the element reaches its target operating temperature (e.g., 1200°C), it is on the flatter part of the curve. At this point, small changes in temperature do not cause large changes in resistance, leading to a stable power draw and a "self-regulating" thermal equilibrium.

Understanding the Practical Trade-offs

While powerful, this behavior comes with practical considerations that must be managed in any design.

High Inrush Current

The rapid drop in resistance means the element can draw a very high current during its initial heat-up phase. Power supplies and controllers must be designed to handle this peak load without failing.

Material Aging

Over hundreds or thousands of hours of operation at high temperatures, silicon carbide slowly oxidizes. This oxidation increases the element's overall resistance. To maintain the same power output and temperature, the applied voltage must be gradually increased over the element's lifespan.

Matching and Batch Variation

Minor differences in manufacturing can lead to slight variations in the resistivity curve between individual SiC elements. For applications requiring multiple elements in series, it is critical to use matched sets from the same batch to ensure they heat evenly and age at a similar rate.

Making the Right Choice for Your Application

Understanding this temperature-resistivity relationship is critical for successful implementation.

- If your primary focus is designing a furnace: You must use a power controller (typically an SCR) that can manage the high inrush current and can be programmed to gradually increase voltage over the element's life to compensate for aging.

- If your primary focus is process control: Your system should account for the rapid initial heating phase and rely on the element's inherent stability at its target operating temperature for consistent performance.

- If your primary focus is material selection: Choose SiC when you need fast, reliable heating to high temperatures (above 1000°C) and can accommodate the necessary power control strategy.

By leveraging silicon carbide's unique semiconductor properties, you can design highly efficient and durable high-temperature systems.

Summary Table:

| Temperature Range | Resistivity Behavior | Key Effect |

|---|---|---|

| Room to ~900°C | Decreases sharply (NTC) | Rapid heat-up due to increased current draw |

| ~800°C to 1000°C | Reaches minimum | Stable operation with self-regulation |

| Above 1000°C | Increases slowly | Maintains performance with minor changes |

Unlock the full potential of silicon carbide heating elements with KINTEK! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental needs. Contact us today to discuss how our tailored solutions can enhance your lab's efficiency and reliability!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What are the operational characteristics of SiC heating elements? Maximize High-Temp Performance and Efficiency

- What is the operating temperature of SiC? Unlock Reliable Performance Up to 1600°C

- What parameters does the IEC standard specify for heating elements? Ensure Safety and Performance

- What is the difference between SiC and MoSi2? Choose the Right High-Temp Heating Element

- What is silicon carbide used for in heating applications? Discover Its High-Temperature Durability