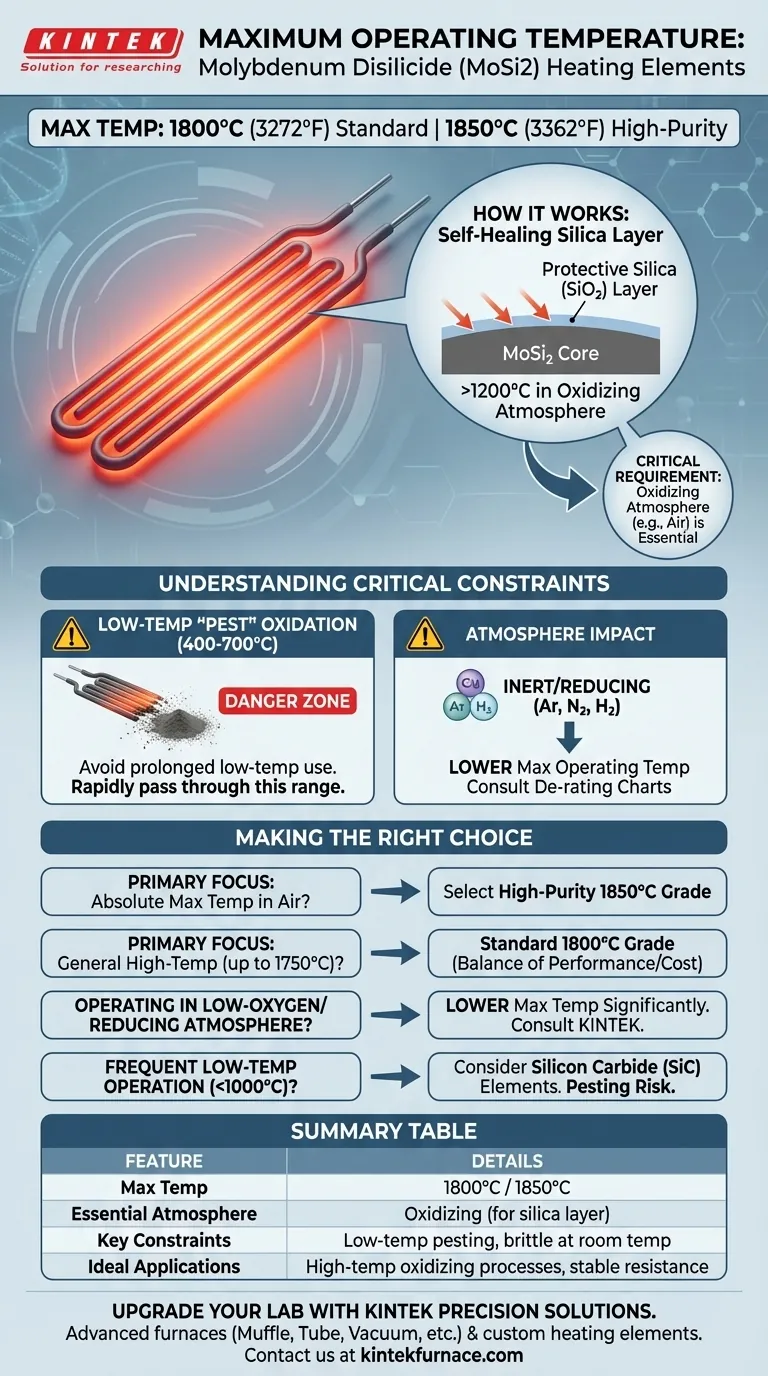

The maximum operating temperature for Molybdenum Disilicide (MoSi2) heating elements is typically 1800°C (3272°F). Certain high-purity grades can extend this limit to an element temperature of 1850°C (3362°F), placing them among the highest-rated metallic electric heating elements available for industrial and laboratory use.

While MoSi2 elements boast an exceptional maximum temperature, their performance is not absolute. This capability is fundamentally dependent on operating in an oxidizing atmosphere, and understanding this dependency is critical to preventing premature failure.

How MoSi2 Achieves Extreme Temperatures

The ability of MoSi2 to function reliably at such high heat is not due to the raw melting point of its components, but rather a remarkable self-healing property that develops during operation.

The Protective Silica (SiO2) Layer

When heated above approximately 1200°C in the presence of oxygen, the surface of the MoSi2 element forms a thin, non-porous layer of quartz glass (silica, or SiO2).

This silica layer acts as a protective barrier, preventing further oxidation of the underlying element material. It is "self-healing," meaning any cracks or spalling that occurs at high temperatures is quickly repaired as new silica forms.

Why an Oxidizing Atmosphere is Essential

The formation and maintenance of this protective silica layer require an oxygen-rich environment. This is the single most important factor for achieving maximum temperature and lifespan.

Without sufficient oxygen, the silica layer cannot form or be repaired. This leads to accelerated degradation of the element, especially in reducing atmospheres like hydrogen or cracked ammonia.

No Operational Aging

A key benefit of this stable, self-regulating silica layer is that MoSi2 elements do not "age" in the traditional sense. Unlike many other element types, their electrical resistance remains stable over long periods, meaning furnace power output does not degrade with use.

Understanding Critical Operating Constraints

Achieving the advertised 1800°C is only possible if you respect the material's specific chemical and physical properties. Ignoring these constraints is the most common cause of element failure.

Low-Temperature "Pest" Oxidation

While exceptional at high temperatures, MoSi2 elements are uniquely vulnerable at low temperatures, specifically between 400°C and 700°C (750°F - 1300°F).

In this range, a destructive form of oxidation known as "pesting" can occur, where the material rapidly disintegrates into a powder. For this reason, furnaces using MoSi2 should be designed to pass through this temperature zone as quickly as possible. The practical operating range begins around 1200°C.

The Impact of Furnace Atmosphere

Operating in a low-oxygen, inert (like Argon or Nitrogen), or reducing atmosphere requires a significant reduction in the maximum operating temperature.

The lack of oxygen prevents the protective silica layer from forming. This forces you to operate at a lower temperature to slow the rate of element degradation. Always consult manufacturer data for de-rating factors based on your specific furnace atmosphere.

Brittleness at Room Temperature

MoSi2 elements are ceramic-like and very brittle at room temperature. They must be handled with extreme care during installation and maintenance to prevent fracture. They only gain ductility when heated to high temperatures.

Making the Right Choice for Your Goal

Your application's specific requirements—especially its atmosphere—are more important than an element's maximum theoretical temperature.

- If your primary focus is reaching the absolute maximum temperature in air: Select a high-purity 1850°C grade and ensure your furnace insulation and process can withstand this heat.

- If your primary focus is general high-temperature processing (up to 1750°C): A standard 1800°C grade provides an excellent balance of extreme performance and cost-effectiveness.

- If you are operating in a low-oxygen or reducing atmosphere: You must lower the maximum operating temperature significantly and should consider MoSi2 only after consulting manufacturer de-rating charts for your specific environment.

- If your process requires frequent or prolonged operation below 1000°C: Be aware of pesting risks and consider Silicon Carbide (SiC) elements, which are better suited for lower-temperature applications.

Ultimately, choosing the correct heating element requires matching the material's properties to the full reality of your operational environment.

Summary Table:

| Feature | Details |

|---|---|

| Max Operating Temperature | 1800°C (3272°F) standard, 1850°C (3362°F) for high-purity grades |

| Essential Atmosphere | Oxidizing (e.g., air) for protective silica layer formation |

| Key Constraints | Avoid low-temperature pesting (400-700°C), brittle at room temperature |

| Ideal Applications | High-temperature processes in oxidizing environments, stable resistance over time |

Upgrade your lab with precision high-temperature solutions from KINTEK! Leveraging exceptional R&D and in-house manufacturing, we provide advanced furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems. Our deep customization capabilities ensure they meet your unique experimental needs, including optimal heating element selection for maximum efficiency and longevity. Contact us today to discuss how our expertise can enhance your research and industrial processes!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- What tasks does a high-temperature vacuum sintering furnace perform for PEM magnets? Achieve Peak Density

- How does the ultra-low oxygen environment of vacuum sintering affect titanium composites? Unlock Advanced Phase Control

- What is the purpose of setting a mid-temperature dwell stage? Eliminate Defects in Vacuum Sintering

- What are the benefits of using a high-temperature vacuum furnace for the annealing of ZnSeO3 nanocrystals?