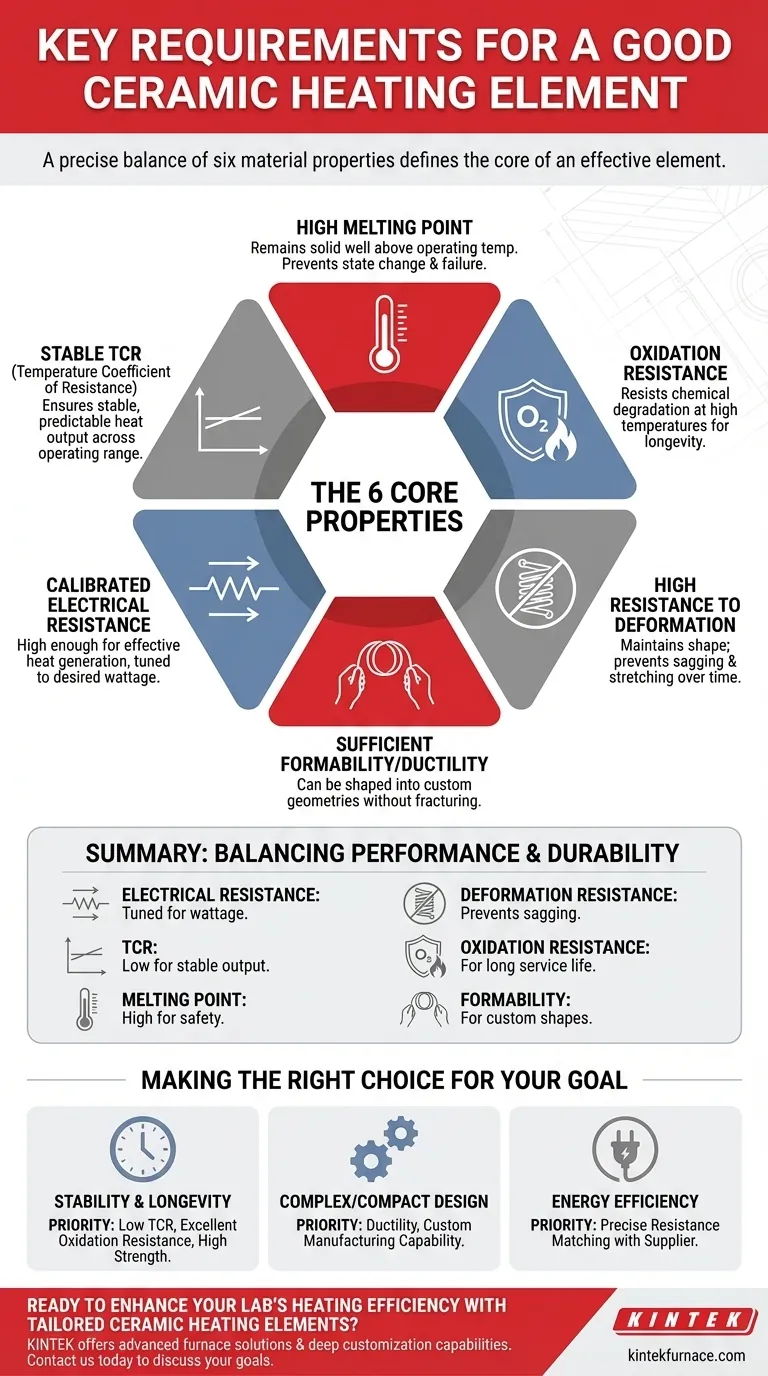

At its core, a good ceramic heating element is defined by a precise balance of six material properties. These are high (but not insulating) electrical resistance, a high melting point, strong resistance to oxidation and high-temperature deformation, a stable temperature coefficient of resistance, and sufficient ductility to be formed into its final shape.

A truly effective ceramic heating element is more than just a material that gets hot. It is a precisely engineered component designed to convert electrical energy into stable, predictable heat while resisting the extreme physical and chemical stresses of its operating environment.

Core Electrical Properties for Efficient Heating

The primary function of a heating element is to convert electricity into heat through a process known as Joule heating. This requires specific electrical characteristics.

Calibrated Electrical Resistance

An element's material must have high electrical resistance to generate heat effectively. If resistance is too low, it will act like a simple wire; if it's too high (insulating), no current will flow at all. The ideal material is a resistor, perfectly tuned to generate the desired wattage at a specific voltage.

Stable Temperature Coefficient of Resistance

The temperature coefficient of resistance (TCR) describes how much a material's resistance changes as its temperature changes. For most heating applications, a low TCR is critical. This ensures that the heat output remains stable and predictable across the operating temperature range, preventing unexpected power spikes or drops. The exception is for self-regulating heaters (PTC), which are designed to have a predictably changing resistance.

Essential Physical & Chemical Durability

A heating element operates in a harsh environment. Its physical and chemical stability is just as important as its electrical performance for ensuring a long and reliable service life.

High Melting Point

This is a fundamental requirement. The element must remain in a solid state well above its maximum operating temperature. A high melting point allows for efficient heat generation without the risk of the material changing state, which would cause immediate failure.

Resistance to High-Temperature Deformation

Beyond simply not melting, the material must possess high "creep strength." It must resist sagging, stretching, or deforming when held at high temperatures for long periods. Maintaining its original shape is critical for consistent performance and preventing electrical shorts.

Resistance to Oxidation

High temperatures dramatically accelerate oxidation, a chemical reaction with oxygen that can degrade the heating material and lead to premature failure. Effective elements are either inherently oxidation-resistant or are protected by a stable, non-conductive oxide layer, often based on silicon or aluminum.

Understanding the Trade-offs: From Material to Manufacturer

While the intrinsic properties of the material are paramount, the "goodness" of a heating element in a real-world application also depends on its manufacturing and the supplier providing it.

Formability and Ductility

The raw heating material must be ductile enough to be shaped into coils, ribbons, or custom geometries without fracturing. The most theoretically perfect material is useless if it cannot be manufactured into the required form factor for your device.

The Role of the Supplier

A premier heating element is often a customized component. A good supplier acts as a technical partner, tailoring the element's wattage, physical size, and voltage to your exact needs. Their experience is crucial for improving your system's energy efficiency and ensuring stable performance.

Verifying Quality and Experience

Look for a manufacturer with deep industry experience and transparent material specifications. Positive customer reviews and responsive technical support are strong indicators that you are choosing a reliable partner, not just a part.

Making the Right Choice for Your Goal

Your specific priority will determine which requirements you should emphasize when selecting an element.

- If your primary focus is stability and long service life: Prioritize materials with a low TCR, excellent oxidation resistance, and high strength at elevated temperatures.

- If your primary focus is a complex or compact design: Emphasize the material's ductility and the manufacturer's capability to produce customized shapes and sizes.

- If your primary focus is maximum energy efficiency: Work closely with a supplier to precisely match the element's resistance and design to your system's voltage and performance targets.

Understanding these key requirements empowers you to select an element that delivers not just heat, but reliable and efficient performance for its intended application.

Summary Table:

| Requirement | Key Details |

|---|---|

| Electrical Resistance | High resistance for effective heat generation, tuned to desired wattage |

| Temperature Coefficient of Resistance (TCR) | Low TCR for stable heat output across temperature ranges |

| Melting Point | High melting point to prevent state change and failure |

| Resistance to Deformation | High creep strength to avoid sagging or stretching at high temperatures |

| Oxidation Resistance | Inherent or protected resistance to oxidation for longevity |

| Formability | Sufficient ductility for shaping into coils, ribbons, or custom geometries |

| Supplier Partnership | Customization of wattage, size, and voltage for optimal efficiency |

Ready to enhance your lab's heating efficiency with tailored ceramic heating elements? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure precise alignment with your unique experimental needs, delivering reliable performance and energy savings. Contact us today to discuss how we can support your specific goals!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- What are the properties and applications of silicon carbide (SiC)? Unlock High-Temperature Performance

- What are the advantages of using high purity green silicon carbide powder in heating elements? Boost Efficiency and Lifespan

- Why are silicon carbide heating elements essential in high-temperature industries? Unlock Reliable, Extreme Heat Solutions

- What makes SIC heating elements superior for high-temperature applications? Unlock Efficiency and Durability

- What makes silicon carbide heating elements resistant to chemical corrosion? Discover the Protective Oxide Layer