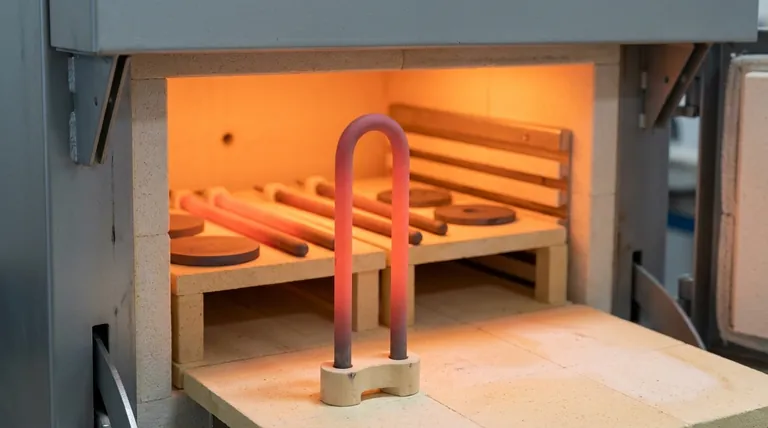

The defining features of MoSi2 heating elements are their exceptional high-temperature performance, a unique self-healing capability in oxygen, and high electrical efficiency. These elements are a specialized cermet composite designed for demanding applications where they can reach surface temperatures of up to 1900°C, far exceeding many alternatives.

Molybdenum Disilicide (MoSi2) elements thrive in extreme heat due to a protective silica layer that forms and "heals" itself during operation. This grants them unparalleled longevity in high-temperature oxidizing environments, but this advantage comes with a critical trade-off: significant brittleness at lower temperatures.

The Core Advantage: High-Temperature Oxidation Resistance

The primary reason to choose MoSi2 elements is their remarkable stability in air at very high temperatures. This is not just a material property but an active, dynamic process.

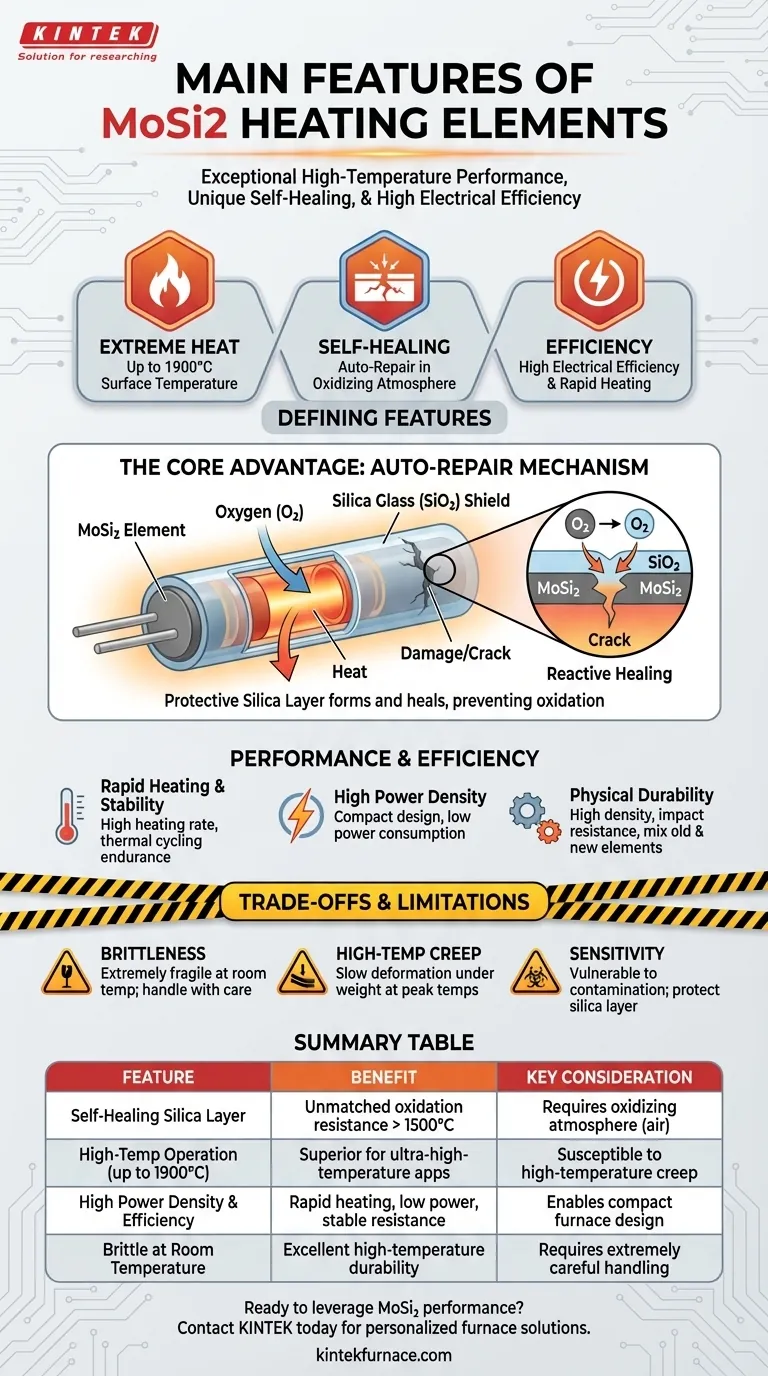

How the "Auto-Repair" Mechanism Works

When a MoSi2 element is heated in an oxygen-rich atmosphere, a thin, non-porous layer of silica glass (SiO2) forms on its surface. This passive layer acts as a protective shield, preventing further oxidation of the underlying element.

If this protective layer is damaged, the exposed MoSi2 material will immediately react with oxygen in the furnace to "heal" the breach with new silica glass, ensuring continuous protection.

Implications for Longevity

This self-healing property gives MoSi2 elements a very long operational life, especially when consistently operated at temperatures above 1500°C. In this range, they significantly outlast other common elements like Silicon Carbide (SiC).

Suitability for Oxidizing Atmospheres

The reliance on oxygen to form the protective layer makes these elements perfectly suited for continuous operation in standard air or other oxidizing furnace atmospheres.

Performance and Efficiency Characteristics

Beyond their high-temperature stability, MoSi2 elements offer several operational benefits that contribute to their performance.

Rapid Heating and Thermal Stability

These elements possess excellent electrical conductivity and a stable resistance profile. This allows for a high heating rate and the ability to endure rapid thermal cycling without significant degradation.

High Power Density

The material's properties allow for a high power concentration, meaning more heat can be generated from a smaller element. This contributes to efficient furnace design and low power consumption for the heat produced.

Physical and Operational Durability

MoSi2 elements are manufactured to a high density, contributing to their durability at peak temperatures. Specialized joint molding and welding techniques provide strong impact resistance, and a unique benefit is that old and new elements can be used together in the same circuit.

Understanding the Trade-offs and Limitations

No material is perfect, and the unique properties of MoSi2 introduce critical limitations that must be understood to ensure successful application.

The Brittleness Problem

MoSi2 is a cermet, a ceramic-metallic composite, which makes it extremely brittle and fragile at room temperature. It behaves like glass. Its toughness only improves significantly above its brittle-ductile transition temperature of approximately 1000°C.

This means the elements must be handled with extreme care during installation and are susceptible to mechanical shock when cold.

High-Temperature Creep

While strong, MoSi2 elements are susceptible to high-temperature creep. Over long periods at peak temperatures, the material can slowly deform under its own weight, which must be accounted for in the furnace design and element support structure.

Sensitivity to Contamination

The integrity of the protective silica layer is paramount. The elements are vulnerable to contamination if certain protocols are not followed, such as failing to properly dry colored zirconia before sintering, which can degrade the element's surface and shorten its life.

Making the Right Choice for Your Application

Selecting the correct heating element requires matching its features to your specific operational needs. MoSi2 elements are a premium choice for a specific set of demanding conditions.

- If your primary focus is ultra-high temperatures (>1500°C) in an air atmosphere: MoSi2 is the superior choice due to its self-healing protective layer and exceptional longevity in this range.

- If your primary focus is operational simplicity and replacement: The ability to mix old and new elements in a series circuit can simplify maintenance and reduce downtime.

- If your application involves frequent mechanical shock or handling at low temperatures: The inherent brittleness of MoSi2 requires careful procedures and may make other, more robust elements a better fit.

Ultimately, choosing MoSi2 is a decision to prioritize unparalleled performance in extreme heat, while accepting the need for careful handling and a controlled operating environment.

Summary Table:

| Feature | Benefit | Key Consideration |

|---|---|---|

| Self-Healing Silica Layer | Unmatched oxidation resistance & longevity above 1500°C | Requires an oxidizing atmosphere (e.g., air) to function |

| High-Temp Operation (up to 1900°C) | Superior performance for ultra-high-temperature applications | Susceptible to high-temperature creep; support is critical |

| High Power Density & Efficiency | Rapid heating, low power consumption, stable resistance | Enables compact and efficient furnace design |

| Brittle at Room Temperature | Excellent high-temperature durability | Requires extremely careful handling during installation |

Ready to leverage the extreme performance of MoSi2 heating elements in your lab?

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD furnace systems, all customizable for your unique high-temperature needs. Our team can help you determine if MoSi2 is the right choice for your application and ensure optimal furnace integration.

Contact KINTEL today to discuss your project and get a personalized solution!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- What makes SIC heating elements superior for high-temperature applications? Unlock Efficiency and Durability

- Why are SiC heating elements considered environmentally friendly? Discover Their Eco-Efficiency & Lifespan Insights

- Why is silicon carbide resistant to chemical reactions in industrial furnaces? Unlock Durable High-Temp Solutions

- Why are SIC heating elements resistant to chemical corrosion? Discover the Self-Protecting Mechanism

- Why are silicon carbide heating elements essential in high-temperature industries? Unlock Reliable, Extreme Heat Solutions