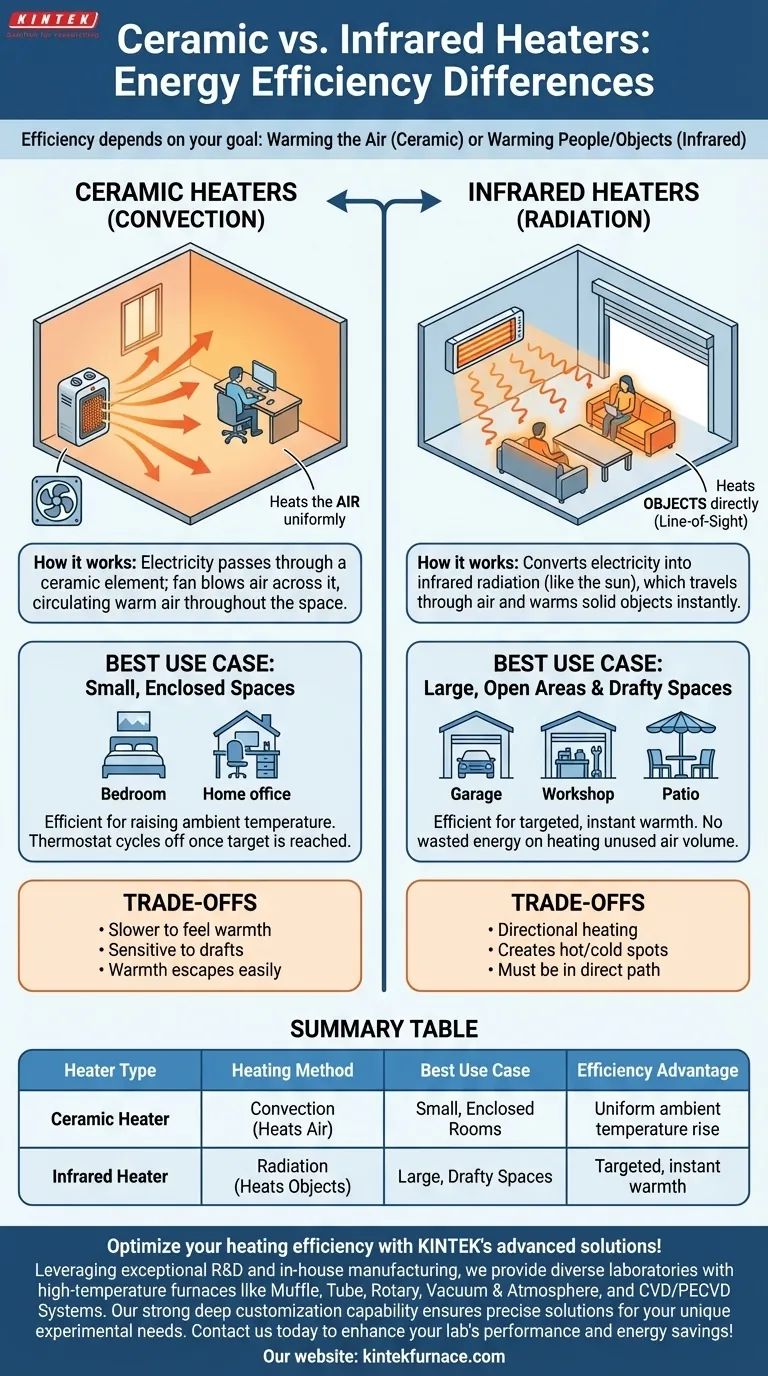

In terms of pure energy efficiency, neither ceramic nor infrared heaters are universally superior. A ceramic heater is more efficient for raising the ambient temperature of a small, enclosed room. An infrared heater is more efficient for delivering targeted warmth to people and objects, especially in a larger or drafty space. The most efficient choice depends entirely on how you intend to use the heat.

The efficiency debate between ceramic and infrared heaters is not about which one uses less electricity per hour, but about how they deliver heat. Your goal determines the winner: do you need to warm the air in a space or the people in that space?

The Fundamental Difference: Heating Air vs. Heating Objects

To understand efficiency, you must first understand the two different physical principles at work. Each technology is designed to solve a different kind of "cold" problem.

How Ceramic Heaters Work: Convection

A ceramic heater works by passing electricity through a self-regulating ceramic heating element. A fan then blows air across this hot element and distributes it into the room.

This process is called convection. It is designed to heat the air itself.

The warm air then circulates throughout the space, gradually raising the overall ambient temperature. This creates a uniform and consistent feeling of warmth.

How Infrared Heaters Work: Radiation

An infrared heater converts electricity into infrared radiation, a type of electromagnetic wave. This is the same principle that allows the sun to warm you from millions of miles away.

These waves travel through the air and are absorbed by solid objects—like you, your furniture, and the floor. This process is called radiation.

This method heats objects and people directly, without needing to heat the volume of air in between. The warmth is felt almost instantly.

How This Impacts Real-World Efficiency

The different heating methods lead to vastly different outcomes for energy efficiency depending on the environment.

The Case for Ceramic: Small, Enclosed Spaces

A ceramic heater is the ideal choice for a bedroom, a small home office, or any well-insulated room where you want to raise the overall temperature.

Because they heat the air evenly, they create a comfortable, ambient warmth throughout the entire space.

This method becomes efficient once the target temperature is reached. The heater's thermostat can then cycle off, conserving energy while the warm air maintains the room's comfort.

The Case for Infrared: Large or Open-Concept Areas

An infrared heater is the clear winner for efficiency in garages, workshops, patios, or large living rooms where heating all the air would be slow and wasteful.

It provides instant, targeted warmth to a specific zone, like a person at a desk or a family on a couch.

This is highly efficient because you are not spending any energy or time heating unused air volume. You are heating only what needs to be warm.

Understanding the Trade-offs

Neither technology is perfect. Acknowledging their limitations is key to making an informed decision.

Ceramic Heaters: Slower to Feel, Sensitive to Drafts

The primary drawback of a ceramic heater is the delay. You must wait for it to heat and circulate enough air to make the room feel warm.

Their effectiveness is also significantly reduced by drafts, open doors, or poor insulation, as the warm air they produce can easily escape.

Infrared Heaters: "Line-of-Sight" Heating

Infrared heat is directional. If you are not in the direct path of the heater's rays, you will not feel their warmth. Moving out of its line of sight is like stepping into the shade on a sunny day.

This can create distinct "hot spots" and "cold spots" in a room, rather than the even, ambient temperature provided by a convection heater.

Shared Benefits: Safety and Portability

It is important to note that modern versions of both heater types are designed with safety in mind. Most models include features like automatic tip-over shutoff and overheat protection.

Both are typically portable, produce no toxic emissions, and offer a simple, effective solution for supplemental heat.

Making the Right Choice for Your Space

To select the most energy-efficient heater, align the technology with your specific heating goal.

- If your primary focus is heating a small, enclosed room (like a bedroom or home office): A ceramic heater is more efficient, as it will evenly raise the ambient temperature of the entire space.

- If your primary focus is heating a person or a specific spot in a large, drafty, or open-plan area (like a garage or living room): An infrared heater is more efficient because it delivers targeted warmth directly to you without wasting energy on the surrounding air.

- If your primary focus is instant warmth for a short period: An infrared heater provides an immediate feeling of heat, while a ceramic heater requires time to warm up the room.

Choosing the right heater is not about finding a superior technology, but about correctly diagnosing your heating problem.

Summary Table:

| Heater Type | Heating Method | Best Use Case | Efficiency Advantage |

|---|---|---|---|

| Ceramic Heater | Convection (heats air) | Small, enclosed rooms | Efficient for raising ambient temperature uniformly |

| Infrared Heater | Radiation (heats objects) | Large, drafty spaces | Efficient for targeted, instant warmth without heating air |

Optimize your heating efficiency with KINTEK's advanced solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems. Our strong deep customization capability ensures precise solutions for your unique experimental needs. Contact us today to enhance your lab's performance and energy savings!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- What is the temperature range for silicon carbide heating elements? Unlock High-Temp Performance from 600°C to 1625°C

- What are the advantages of silicon carbide heating elements in dental furnaces? Boost Zirconia Sintering Quality

- What is silicon carbide used for in heating applications? Discover Its High-Temperature Durability

- What is the difference between SiC and MoSi2? Choose the Right High-Temp Heating Element

- What heating elements are used in high-temperature tube furnaces? Discover SiC and MoSi2 for Extreme Heat