At their core, SC Type Silicon Carbide (SiC) heating elements are handled and packaged with extreme care, similar to sensitive ceramic or glass instruments. Because they are inherently hard and brittle, all packaging is designed to prevent mechanical shock, vibration, and bending stress during shipping and storage. Handling procedures must continue this focus, treating them as fragile components to avoid micro-fractures that can lead to premature failure.

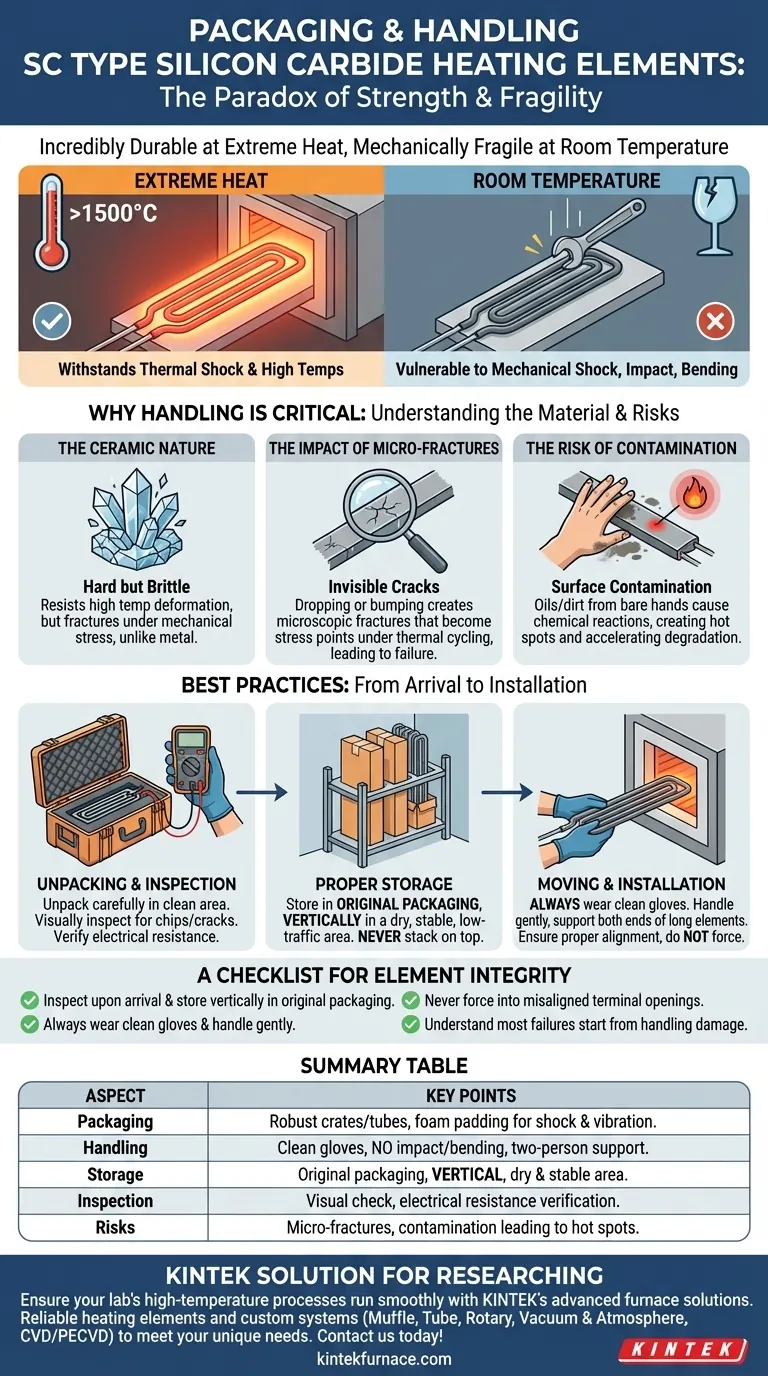

The central principle for handling SiC elements is recognizing their paradox: they are incredibly durable at extreme temperatures but mechanically fragile at room temperature. Proper handling is not about protecting them from heat, but from physical impact, bending, and contamination.

Understanding the Material: Why Handling is Critical

The exceptional high-temperature performance of SC Type SiC elements is a direct result of their material composition and design. Understanding these characteristics reveals why specific handling protocols are not just recommended, but essential for their operational life.

The Ceramic Nature: Hard but Brittle

Silicon carbide is a ceramic material. Like many advanced ceramics, it is extremely hard and resistant to deformation at high temperatures. However, this hardness comes with brittleness.

It does not bend or dent when stressed; it fractures. An impact that would merely scratch a metal component can cause a catastrophic failure in a SiC element.

The Impact of Micro-Fractures

The most significant risk during handling is the creation of microscopic fractures. Dropping a tool on an element, bumping it against a furnace wall, or even setting it down too hard can create tiny, invisible cracks.

These micro-fractures may not cause immediate breakage. However, once the element is installed and subjected to intense thermal cycling, these small imperfections become stress points, leading to a crack that propagates and causes the element to fail.

The Risk of Contamination

Handling elements with bare hands can transfer oils, moisture, and dirt onto the element's surface. At operating temperatures, these contaminants can react with the silicon carbide or its protective glaze.

This chemical reaction can alter the element's electrical resistance in that spot, creating a hot spot that accelerates local degradation and ultimately leads to failure.

Best Practices for Packaging and Handling

Proper handling begins the moment the elements arrive and continues through installation. The manufacturer's packaging is your first guide.

Unpacking and Initial Inspection

Elements are typically shipped in robust crates or tubes with extensive foam padding to isolate them from shock. Unpack them carefully in a clean, open area.

Visually inspect each element for any signs of damage, such as chips or cracks, that may have occurred during transit. Check the electrical resistance with a multimeter and compare it to the value marked on the element; a significant deviation may indicate internal damage.

Proper Storage

If not being installed immediately, store the elements in their original packaging.

Keep them in a dry, stable environment away from high-traffic areas where they could be bumped. It is best practice to store them vertically if possible, or as directed by the manufacturer, to prevent any long-term stress from their own weight. Never stack anything on top of the elements.

Moving and Installation

When moving the elements, always handle them with care, avoiding any impact or bending. For longer elements, use two people, supporting the element at both ends.

Always wear clean gloves to prevent contamination. Ensure the path to the furnace is clear and that terminal holes are properly aligned to avoid forcing the element into place. Never use the element itself to check the alignment of furnace openings.

Understanding the Trade-offs: The Fragility of Precision

The SC Type's single spiral design is excellent for creating a uniform heating field, which is critical in large industrial and laboratory furnaces. However, this precision comes with inherent trade-offs.

High Performance vs. Mechanical Sensitivity

The spiral cut that gives the element its excellent thermal properties also makes it more mechanically sensitive than a simple solid rod. This sophisticated design is less forgiving of physical stress.

Thermal Resistance vs. Mechanical Vulnerability

SiC elements are engineered to withstand extreme thermal shock, meaning they can heat and cool rapidly without damage. This is a common point of confusion.

Their resistance to thermal shock has no bearing on their extreme vulnerability to mechanical shock. A dropped wrench is a far greater threat to a cold element than a rapid temperature ramp-up.

A Checklist for Element Integrity

To ensure the longevity and reliability of your SC Type SiC elements, treat every handling step with deliberate care. Your goal is to get the element from its packaging to its operating temperature without introducing any physical stress or contamination.

- If your primary focus is receiving and storage: Inspect every element upon arrival and store them vertically in their original packaging in a safe, dry location.

- If your primary focus is installation: Always wear clean gloves, handle the elements gently to avoid any impact, and never force them into misaligned terminal openings.

- If your primary focus is operational reliability: Understand that most premature failures originate from microscopic damage sustained during handling long before the element is ever powered on.

Proper handling is the first and most critical step in achieving reliable, high-temperature performance from your heating system.

Summary Table:

| Aspect | Key Points |

|---|---|

| Packaging | Robust crates/tubes with foam padding to prevent shock, vibration, and bending stress |

| Handling | Use clean gloves, avoid impact and bending, support long elements with two people |

| Storage | Keep in original packaging, store vertically in dry, stable areas |

| Inspection | Check for chips/cracks, verify electrical resistance with multimeter |

| Risks | Micro-fractures from impact, contamination from oils/dirt leading to hot spots |

Ensure your lab's high-temperature processes run smoothly with KINTEK's advanced furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable heating elements and custom systems like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capability precisely meets your unique experimental needs, enhancing performance and durability. Contact us today to discuss how we can support your specific requirements!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- Why are silicon carbide heating elements essential in high-temperature industries? Unlock Reliable, Extreme Heat Solutions

- Why is silicon carbide resistant to chemical reactions in industrial furnaces? Unlock Durable High-Temp Solutions

- What are the properties and applications of silicon carbide (SiC)? Unlock High-Temperature Performance

- What are the properties and capabilities of Silicon Carbide (SiC) as a heating element? Unlock Extreme Heat and Durability

- What makes SIC heating elements superior for high-temperature applications? Unlock Efficiency and Durability