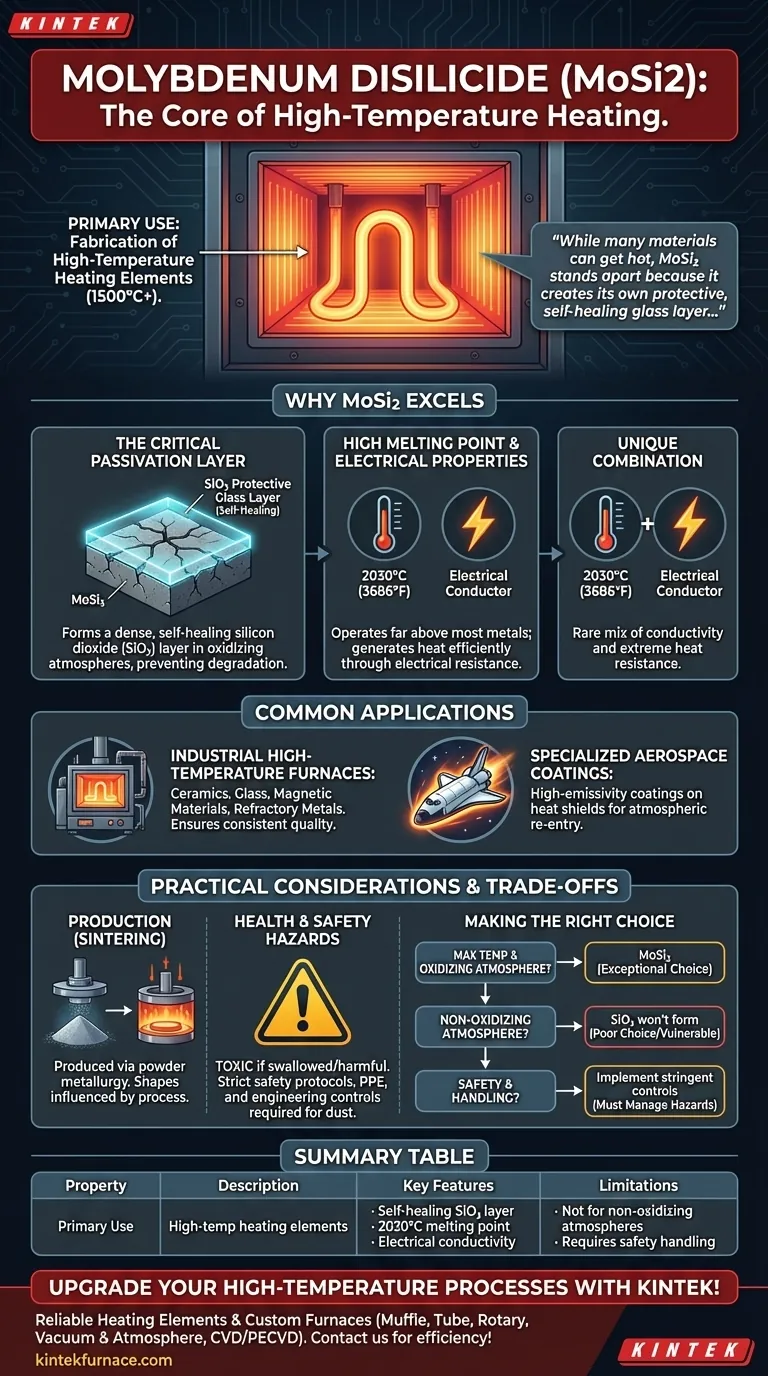

The primary use of molybdenum disilicide (MoSi2) is the fabrication of high-temperature heating elements. This advanced ceramic material is essential for industrial furnaces and other applications that require reliable, sustained heat in extreme environments, often exceeding 1500°C. Its utility stems from a unique combination of electrical conductivity, a very high melting point, and remarkable resistance to oxidation.

While many materials can get hot, molybdenum disilicide stands apart because it creates its own protective, self-healing glass layer at high temperatures. This unique characteristic is the key to its exceptional longevity and reliability in the most demanding industrial heating applications.

Why MoSi2 Excels in High-Temperature Environments

Molybdenum disilicide is not simply a material that resists heat; its properties work in concert to create a robust and durable heating system. Understanding its behavior at a molecular level reveals why it is a superior choice for extreme temperatures.

The Critical Passivation Layer

The most important property of MoSi2 is its ability to form a thin, protective layer of silicon dioxide (SiO₂) on its surface when heated in an oxidizing atmosphere. This layer is essentially a form of glass.

This passivation layer is dense and self-healing. If a crack or defect forms, the exposed MoSi2 reacts with oxygen in the air to immediately reform the protective glass coating, preventing the underlying material from degrading.

This behavior gives MoSi2 heating elements exceptional resistance to high-temperature oxidation and corrosion, leading to a significantly longer service life compared to many metallic alternatives.

High Melting Point and Electrical Properties

To function as a heating element, a material needs two fundamental properties: it must allow electricity to flow through it (resistance heating), and it must not melt at its operating temperature.

MoSi2 has a very high melting point of 2030°C (3686°F), allowing it to operate at temperatures where most metals would fail.

Simultaneously, it is an electrical conductor, allowing it to generate heat efficiently through electrical resistance. This combination is relatively rare among ceramic materials, which are often electrical insulators.

Common Applications in Industry

The unique properties of MoSi2 make it indispensable in several high-value industrial processes that require stable and precise high temperatures.

Industrial High-Temperature Furnaces

MoSi2 heating elements are the standard for electric furnaces used in the production and processing of ceramics, glass, magnetic materials, and refractory metals.

Their ability to maintain temperature stability and resist the harsh chemical environments inside these furnaces ensures consistent product quality and reduces costly downtime.

Specialized Aerospace Coatings

Beyond heating elements, MoSi2 is also used in specialized high-emissivity coatings. These are applied to heat shields for applications like atmospheric re-entry vehicles.

In this role, the material's ability to efficiently radiate thermal energy away from a surface is just as important as its ability to withstand extreme heat.

Understanding the Practical Considerations and Trade-offs

While powerful, MoSi2 is a specialized material with specific handling requirements and limitations that are critical to understand for safe and effective implementation.

Production and Fabrication

MoSi2 components are typically produced via sintering, a powder metallurgy process that fuses particles together under high temperature and pressure.

This process influences the available shapes and sizes of heating elements. More complex geometries can be produced through methods like plasma spraying, but this can introduce different material phases and properties.

Health and Safety Hazards

Molybdenum disilicide is not a benign substance. It is classified as toxic if swallowed and harmful if inhaled or in contact with skin.

Handling MoSi2 powder or performing any machining that creates dust requires strict safety protocols. This includes the use of respiratory protection, gloves, and protective clothing, along with thorough washing after handling.

Making the Right Choice for Your Application

Selecting MoSi2 is a decision based on performance requirements, operating environment, and safety considerations.

- If your primary focus is maximum operating temperature and long service life: MoSi2 is an exceptional choice for electric furnaces and heaters that must operate reliably above 1500°C in an oxidizing atmosphere.

- If your primary focus is operating in a non-oxidizing atmosphere: The protective SiO₂ layer will not form, making MoSi2 vulnerable to degradation and a poor choice for vacuum or reducing environments.

- If your primary focus is safety and handling: You must be prepared to implement stringent engineering controls and provide personal protective equipment to manage the health hazards associated with MoSi2 dust.

By understanding its unique self-healing properties and practical limitations, you can effectively leverage molybdenum disilicide for the most demanding high-temperature applications.

Summary Table:

| Property | Description |

|---|---|

| Primary Use | High-temperature heating elements for industrial furnaces |

| Key Features | Self-healing SiO₂ layer, high melting point (2030°C), electrical conductivity |

| Common Applications | Ceramics, glass production, aerospace coatings |

| Limitations | Not suitable for non-oxidizing atmospheres; requires safety handling for dust |

Upgrade your high-temperature processes with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable heating elements and custom high-temperature furnaces, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capability ensures precise fit for your unique experimental needs. Contact us today to discuss how we can enhance your efficiency and performance!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What tasks does a high-temperature vacuum sintering furnace perform for PEM magnets? Achieve Peak Density

- What is the purpose of setting a mid-temperature dwell stage? Eliminate Defects in Vacuum Sintering

- What is the role of vacuum pumps in a vacuum heat treatment furnace? Unlock Superior Metallurgy with Controlled Environments

- Why is a vacuum environment essential for sintering Titanium? Ensure High Purity and Eliminate Brittleness

- What are the benefits of using a high-temperature vacuum furnace for the annealing of ZnSeO3 nanocrystals?