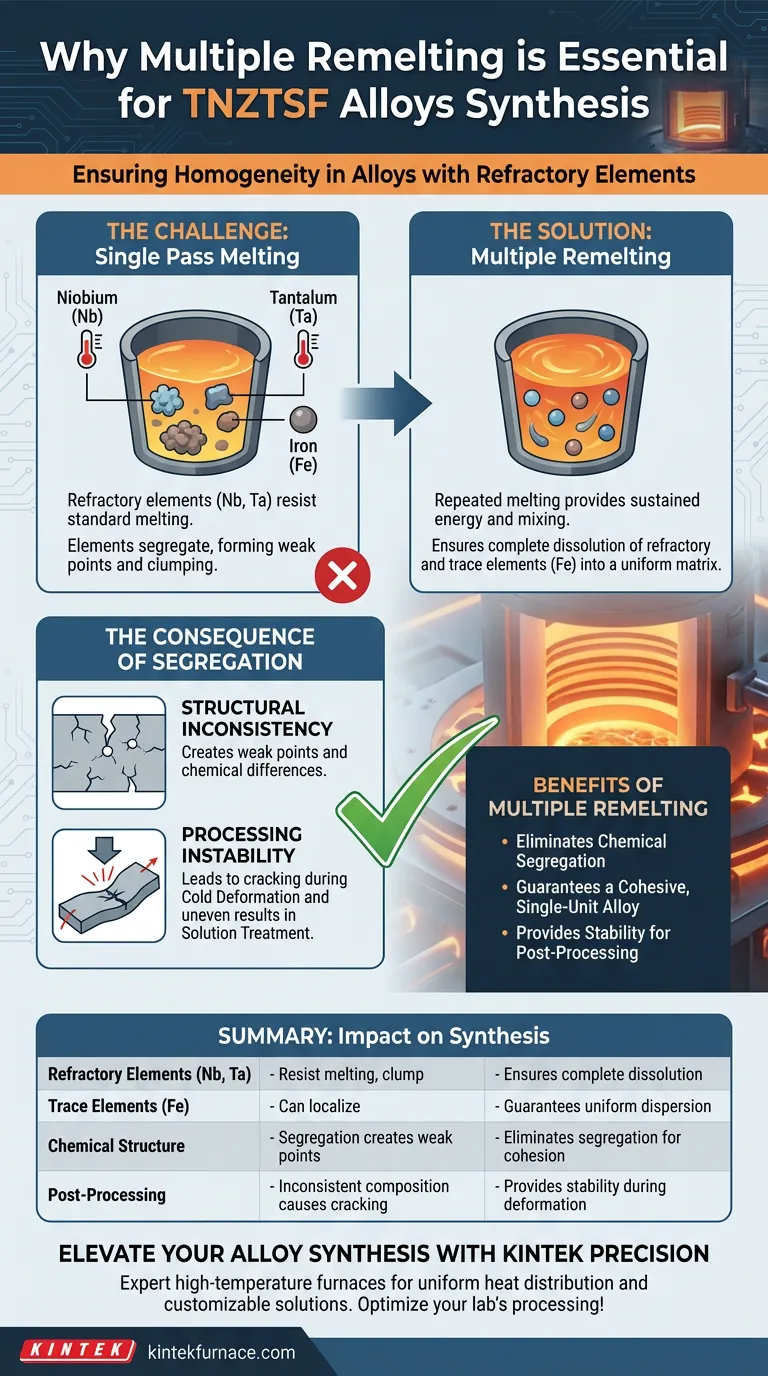

Multiple remelting cycles are essential to achieve the necessary chemical homogeneity within TNZTSF alloys. Because these alloys contain refractory elements with high melting points, specifically Niobium (Nb) and Tantalum (Ta), a single melting pass is insufficient to distribute them evenly. Repeated melting ensures these heavy components, along with trace elements like Iron (Fe), are thoroughly mixed to eliminate chemical segregation.

Refractory elements resist standard melting; without multiple cycles, they clump together and compromise the alloy's integrity. Remelting is the primary mechanism for ensuring a uniform chemical structure that remains stable during later processing.

The Challenge of Refractory Elements

Overcoming High Melting Points

Niobium (Nb) and Tantalum (Ta) are refractory metals known for their exceptional resistance to heat.

Because they have significantly higher melting points than other alloy constituents, they do not dissolve easily.

Multiple remelting provides the sustained energy and mixing required to fully integrate these stubborn elements into the alloy matrix.

Distributing Trace Elements

The synthesis process must also account for trace elements such as Iron (Fe).

While less resistant than refractory metals, these elements still risk becoming localized within the material.

Remelting ensures these trace components are dispersed uniformly rather than concentrating in specific pockets.

The Consequence of Segregation

Preventing Structural Inconsistency

Chemical segregation occurs when elements separate or clump rather than forming a solid solution.

In TNZTSF alloys, segregation creates weak points where the chemical composition differs from the rest of the material.

Eliminating this segregation through remelting is the only way to guarantee the alloy acts as a single, cohesive unit.

Ensuring Processing Stability

The benefits of homogeneity extend beyond the initial synthesis.

A uniform chemical structure is a prerequisite for stable performance during subsequent manufacturing steps.

Specifically, it ensures the material behaves predictably during cold deformation and solution treatment phases.

Understanding the Risks

Impact on Cold Deformation

If chemical segregation is present, the alloy will not deform continuously under stress.

Inconsistent areas caused by undissolved Niobium or Tantalum can lead to stress concentrations.

This often results in unexpected failure or cracking during the cold deformation process.

Issues with Solution Treatment

Solution treatment relies on a uniform starting microstructure to be effective.

If the elements are not evenly distributed, the heat treatment will produce uneven results across the alloy.

This lack of uniformity compromises the final mechanical properties of the material.

Ensuring Material Integrity

To achieve a high-performance TNZTSF alloy, the initial synthesis must prioritize total chemical integration.

- If your primary focus is structural durability: Prioritize multiple remelting cycles to eliminate weak points caused by the segregation of Niobium and Tantalum.

- If your primary focus is manufacturing efficiency: Ensure the alloy is fully homogenized to prevent material failure during cold deformation and heat treatment.

A rigorous approach to initial melting creates the foundation for a reliable, defect-free material.

Summary Table:

| Factor | Impact on TNZTSF Synthesis | Benefit of Multiple Remelting |

|---|---|---|

| Refractory Elements | Nb and Ta resist melting and tend to clump | Ensures complete dissolution into the alloy matrix |

| Trace Elements | Iron (Fe) can localize in specific pockets | Guarantees uniform dispersion throughout the material |

| Chemical Structure | Segregation creates structural weak points | Eliminates segregation for a cohesive, single-unit alloy |

| Post-Processing | Inconsistent composition causes cracking | Provides stability during cold deformation and heat treatment |

Elevate Your Alloy Synthesis with KINTEK Precision

Don't let chemical segregation compromise your material integrity. Achieving the perfect homogeneity in TNZTSF alloys requires the right high-temperature environment. Backed by expert R&D and world-class manufacturing, KINTEK offers a comprehensive range of Vacuum, CVD, Muffle, and customizable lab high-temperature furnaces designed to handle the rigorous demands of refractory elements like Niobium and Tantalum.

Our value to you:

- Uniform Heat Distribution: Critical for eliminating weak points in complex alloys.

- Customizable Solutions: Tailored systems to meet your specific melting and synthesis requirements.

- Expert Engineering: High-performance equipment that ensures stability during subsequent cold deformation.

Contact KINTEK today to optimize your lab's high-temperature processing!

Visual Guide

References

- Vasile Dănuț Cojocaru, Bogdan Mihai Gălbinaşu. The Effect of Solution Treatment Duration on the Microstructural and Mechanical Properties of a Cold-Deformed-by-Rolling Ti-Nb-Zr-Ta-Sn-Fe Alloy. DOI: 10.3390/ma17040864

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- What are the advantages of vacuum induction melting and casting (VIM&C) over VIM? Achieve Superior Metallurgical Quality and Efficiency

- Which types of metals benefit most from vacuum or protective atmosphere melting? Essential for Reactive Metals and Alloys

- Why is a vacuum environment important in a VIM furnace? Unlock Purity and Performance in Metal Melting

- What is induction brazing and where is it used? Unlock Fast, Precise Metal Joining for Industry

- How scalable are induction gold melting furnaces for different operations? From Jewelry to Industrial Refining

- What is the disadvantage of an induction furnace? Its Core Limitation in Metal Refining

- What is the primary function of a vacuum induction furnace in silicon steel smelting? Achieve Unmatched Purity

- What are the safety measures for a Vacuum Induction Melting Furnace? Essential Protocols for Hazard Prevention