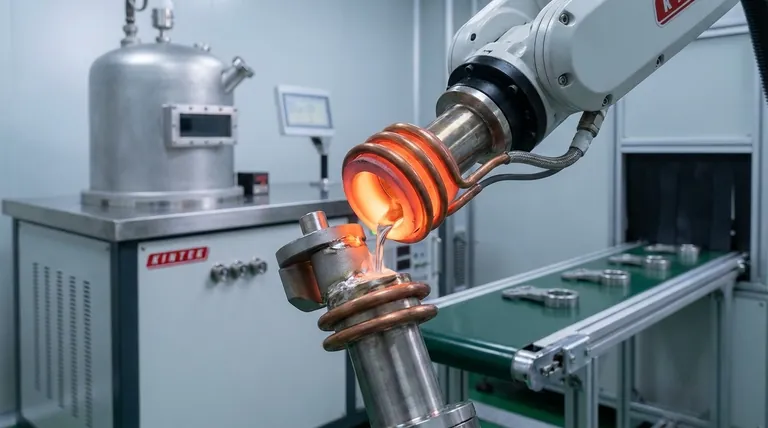

At its core, induction brazing is a joining process that uses a non-contact heating method to join two or more metal components. An alternating electromagnetic field precisely heats the parts, melting a filler metal (the braze alloy) which flows between them and solidifies to create a strong, permanent bond. Its primary advantages are exceptional speed, precision, and repeatability, making it a cornerstone of modern industrial manufacturing.

While many processes can join metal, induction brazing's unique value is its ability to deliver clean, highly-controlled heat almost instantaneously. This transforms brazing from a manual craft into a reliable, automated industrial process ideal for high-volume production lines.

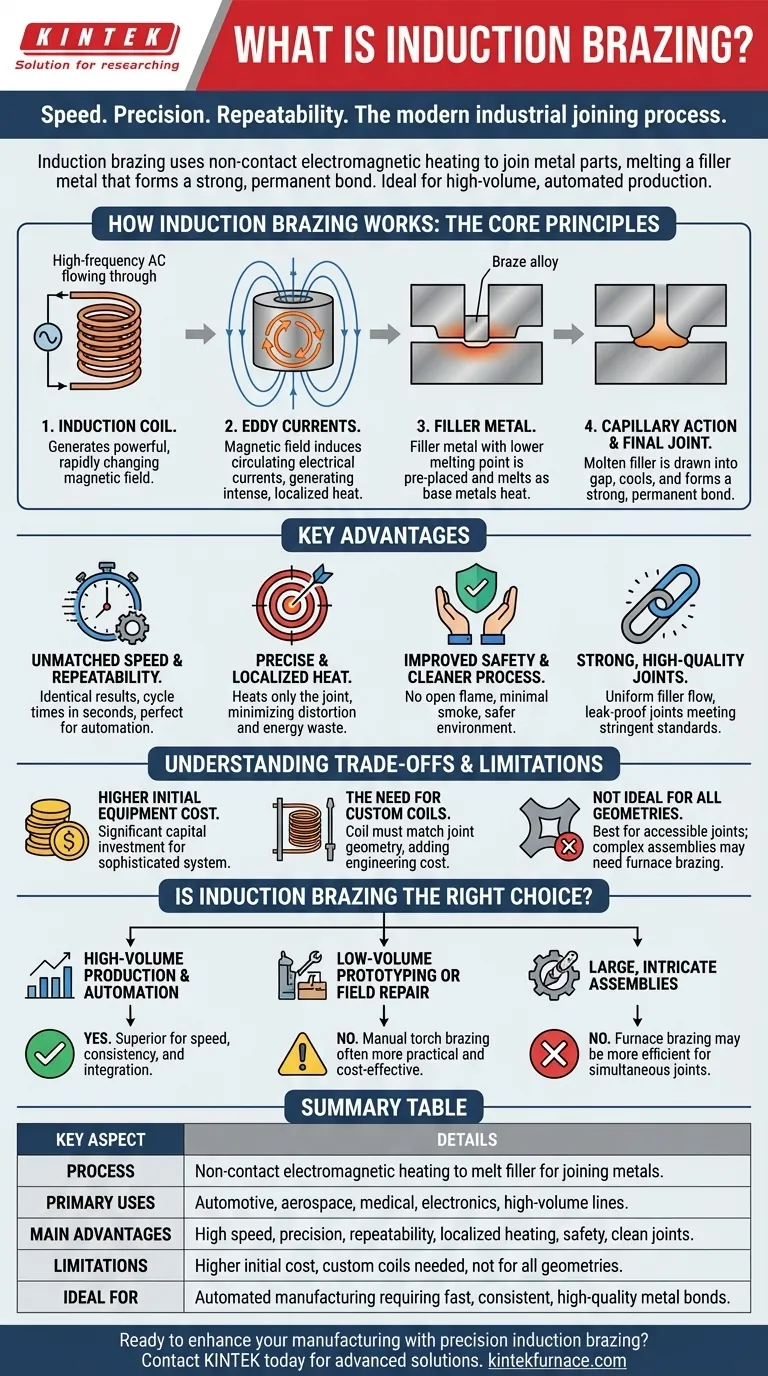

How Induction Brazing Works: The Core Principles

Understanding induction brazing requires looking beyond the final joint and focusing on the physics that make it so efficient. The process is a sequence of controlled electromagnetic and thermal events.

The Role of the Induction Coil

The heart of the system is a custom-shaped copper coil. When a high-frequency alternating current (AC) is passed through this coil, it generates a powerful and rapidly changing magnetic field in the space around it.

Generating Heat with Eddy Currents

When a conductive metal part is placed within this magnetic field (without touching the coil), the field induces circulating electrical currents within the metal. These are known as eddy currents. The metal's natural resistance to the flow of these currents generates intense, localized heat directly within the part itself.

The Function of the Filler Metal

A filler metal, or braze alloy, with a melting point lower than the base metals being joined, is pre-placed at the joint. As the base metals heat up via induction, they conduct that heat to the filler, causing it to melt and become liquid.

Capillary Action and the Final Joint

Once molten, the filler metal is drawn into the tight gap between the components through a phenomenon called capillary action. After the heating cycle ends—often in just a few seconds—the filler cools and solidifies, forming a strong, permanent metallurgical bond between the parts.

Key Advantages in Industrial Settings

The principles of induction heating give this process distinct advantages that make it the preferred choice for specific, demanding applications.

Unmatched Speed and Repeatability

Because the process is controlled by precise electrical parameters (power, frequency, and time), the results are identical from the first part to the ten-thousandth. This eliminates the variability of manual heating and allows for cycle times measured in seconds, perfect for automated assembly lines.

Precise and Localized Heat

Induction heating is incredibly focused. Only the area of the joint is heated to brazing temperature, leaving the rest of the component unaffected. This minimizes part distortion, protects nearby heat-sensitive materials, and reduces energy waste compared to heating an entire part in a furnace.

Improved Safety and a Cleaner Process

With no open flame, induction brazing is significantly safer than torch brazing. The process produces minimal smoke or fumes, creating a cleaner work environment. This often eliminates the need for extensive post-braze cleaning, further streamlining production.

Strong, High-Quality Joints

The uniform and rapid heating ensures the filler metal flows evenly throughout the joint, minimizing the risk of voids or defects. This results in consistently strong, leak-proof joints that meet stringent quality standards in industries like automotive and aerospace.

Understanding the Trade-offs and Limitations

No process is perfect for every situation. Being a trusted advisor means recognizing the limitations of a technology.

Higher Initial Equipment Cost

An induction heating system represents a more significant capital investment than a simple torch setup. The power supply, water-cooling system, and controls are sophisticated pieces of equipment.

The Need for Custom Coils

The induction coil must be designed and shaped to match the specific geometry of the joint. This "tooling" requirement adds an engineering step and cost, making the process less economical for one-off jobs or very low-volume production runs.

Not Ideal for All Geometries

While versatile, induction is best suited for joints with well-defined, accessible geometries. Brazing many joints simultaneously on a large, complex assembly can be more efficiently handled by furnace brazing, which heats the entire part in a single cycle.

Is Induction Brazing the Right Choice for Your Application?

Selecting the correct joining method is a strategic decision that impacts cost, quality, and throughput. Your goal should dictate your choice.

- If your primary focus is high-volume production and automation: Induction brazing is the superior choice due to its unmatched speed, consistency, and ease of integration into an assembly line.

- If your primary focus is low-volume prototyping or field repair: The simplicity and low entry cost of manual torch brazing will almost always be more practical and cost-effective.

- If your primary focus is joining large, intricate assemblies with many joints: Furnace brazing often provides a more efficient solution by heating the entire part in a controlled atmosphere, ensuring all joints are made at once.

Ultimately, choosing induction brazing is a decision to prioritize precision, speed, and repeatability within a structured manufacturing environment.

Summary Table:

| Key Aspect | Details |

|---|---|

| Process | Non-contact heating using electromagnetic fields to melt filler metal for joining metals |

| Primary Uses | Automotive, aerospace, medical devices, electronics, and high-volume production lines |

| Main Advantages | High speed, precision, repeatability, localized heating, safety, and clean joints |

| Limitations | Higher initial cost, need for custom coils, not ideal for all geometries or low volumes |

| Ideal For | Automated manufacturing requiring fast, consistent, and high-quality metal bonds |

Ready to enhance your manufacturing with precision induction brazing? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we can precisely meet your unique experimental and production needs. Contact us today via our contact form to discuss how our tailored solutions can boost your efficiency and quality in high-volume industrial applications!

Visual Guide

Related Products

- HFCVD Machine System Equipment for Drawing Die Nano Diamond Coating

- Molybdenum Vacuum Heat Treat Furnace

- MPCVD Machine System Reactor Bell-jar Resonator for Lab and Diamond Growth

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Ultra Vacuum Electrode Feedthrough Connector Flange Power Lead for High Precision Applications

People Also Ask

- What are the advantages of using a vacuum induction melting furnace? Achieve Unmatched Purity and Control

- What makes induction vacuum melting possible? Unlock Ultra-Pure Metal Production

- How do the crucible material and configuration differ in the inductive heating evaporation process? A Guide to Direct vs. Indirect Heating

- How does IGBT enhance efficiency and energy savings in induction melting? Achieve Superior Control and Lower Costs

- Why are electromagnetic stirring and repeated melting cycles necessary? Achieving Homogeneity in (AlTiV)100−xCrx Alloys

- What are the technical advantages of using an induction furnace for lithium battery recycling over resistance heating?

- What principle does an induction heater circuit operate on? Discover Efficient, Contactless Heating

- What is the primary role of a vacuum pump in induction brazing? Achieve Pure, Contamination-Free Research Results