In short, induction gold melting furnaces are exceptionally scalable. They are engineered to serve operations of nearly any size, from a small artisan jewelry shop melting a few grams at a time to a large-scale industrial refinery processing many kilograms in a single batch. This inherent flexibility is one of the primary reasons for their widespread adoption.

The core decision is not whether induction technology can scale to your needs, but rather how to select the right capacity. Choosing the correct size involves a critical trade-off between melt volume, upfront investment, and your facility's power infrastructure.

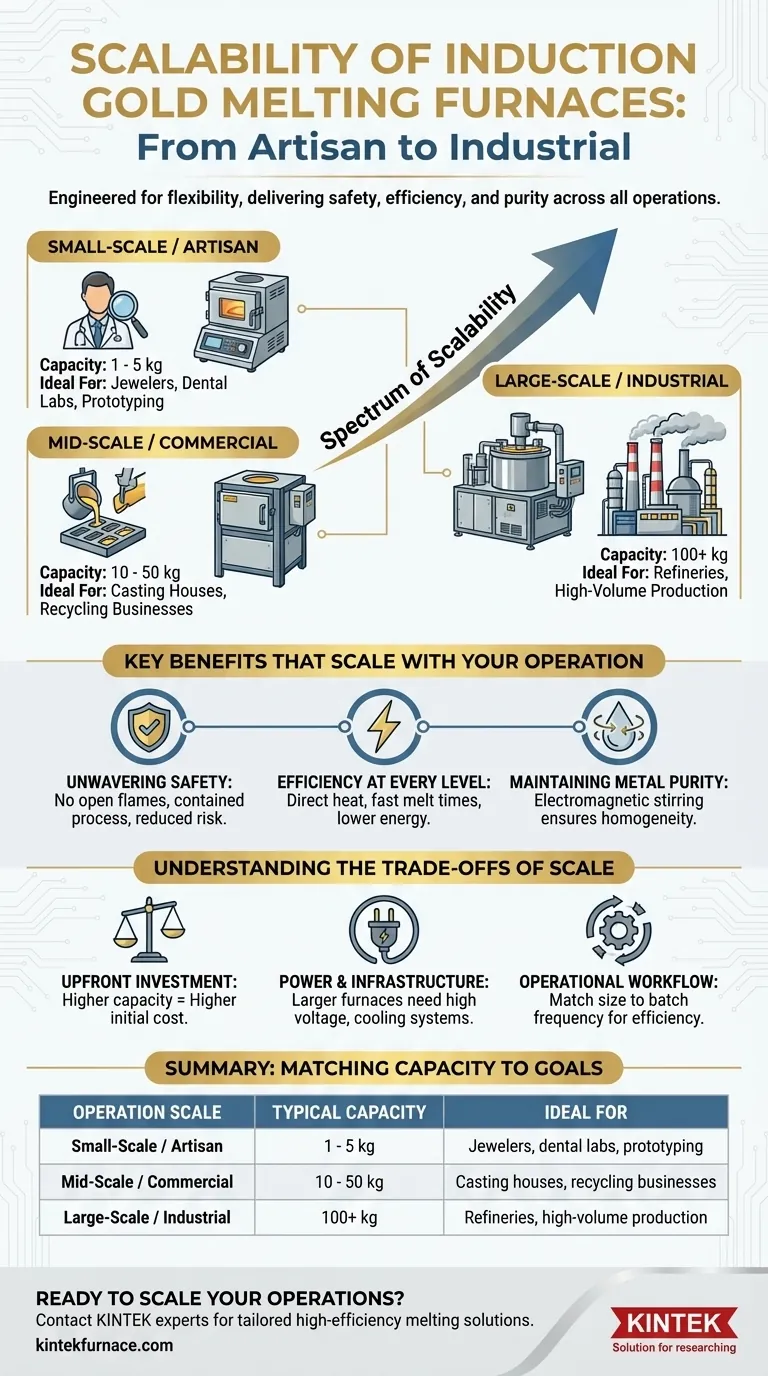

The Spectrum of Scalability

Induction melting technology's scalability stems from its fundamental design. The heating principle remains the same regardless of size, allowing manufacturers to produce units with a vast range of capacities.

From Benchtop to Industrial Floor

Small, benchtop induction furnaces are designed for capacities as low as 1-2 kilograms. These units are perfect for jewelers, dental labs, or small-scale prototyping where precision and quick, small batches are required.

On the other end of the spectrum, large industrial induction furnaces can hold hundreds of kilograms of gold. These are built for refineries and large-scale recycling operations where throughput is the primary driver.

The Core Technology is Consistent

The scalability works because the underlying method—using an electromagnetic field to generate heat directly within the gold—is efficient at any size. The core components (a power supply and a coil-wrapped crucible) are simply engineered to be larger and more powerful to handle increased volume.

Key Benefits That Scale with Your Operation

Certain advantages of induction melting are present regardless of the furnace's size, making it a reliable choice for any business.

Unwavering Safety Profile

Induction furnaces operate without an open flame or external heating elements. The process is contained within a sealed crucible, which significantly reduces the risk of burns, fires, and exposure to toxic fumes compared to traditional torch or gas furnace methods. This high level of safety is a constant benefit for a one-person shop or a hundred-person refinery.

Efficiency at Every Level

Induction heating is incredibly direct and fast. Because the heat is generated within the metal itself, energy transfer is highly efficient, leading to faster melt times and lower energy consumption per kilogram compared to other methods. This efficiency holds true for both small and large batches.

Maintaining Metal Purity

The electromagnetic stirring action inherent in the induction process creates a homogeneous, evenly mixed molten bath. This helps burn off impurities and prevents segregation of alloys, ensuring a high-quality, consistent final product, which is critical for operations of any size.

Understanding the Trade-offs of Scale

While the technology is scalable, choosing a furnace size requires careful consideration of the associated trade-offs.

Upfront Investment vs. Capacity

The most direct trade-off is cost. Larger furnaces with higher melt capacities and more powerful systems command a significantly higher initial investment. Over-specifying a furnace for your needs leads to unnecessary capital expenditure.

Power and Infrastructure Demands

A small, 1-2 kg furnace might run on a standard single-phase power supply. In contrast, a large industrial furnace requires a high-voltage, three-phase power connection and often a dedicated water-cooling system. Your facility's existing infrastructure may be a limiting factor when scaling up.

Operational Workflow

A smaller furnace is ideal for frequent, on-demand melting of various alloys. A larger furnace is more efficient for continuous, single-alloy production runs. Choosing the wrong size can create bottlenecks or inefficiencies in your daily workflow.

Making the Right Choice for Your Goal

Selecting the right furnace is about aligning the equipment's capacity with your specific business objectives.

- If your primary focus is custom jewelry or small-batch artistry: A small benchtop unit (1-5 kg) offers the flexibility and low startup cost you need for on-demand melting.

- If your primary focus is a mid-sized casting house or recycling business: A medium-capacity floor model (10-50 kg) provides a balance of throughput and versatility for handling varied batch sizes.

- If your primary focus is large-scale refining or industrial production: A high-capacity furnace (100+ kg) is necessary to achieve the economy of scale and high throughput required for profitability.

Ultimately, choosing an induction furnace is a strategic investment in the safety, efficiency, and quality of your melting operations.

Summary Table:

| Operation Scale | Typical Furnace Capacity | Ideal For |

|---|---|---|

| Small-Scale / Artisan | 1 - 5 kg | Jewelers, dental labs, prototyping |

| Mid-Scale / Commercial | 10 - 50 kg | Casting houses, recycling businesses |

| Large-Scale / Industrial | 100+ kg | Refineries, high-volume production |

Ready to Scale Your Gold Melting Operations with Precision?

Whether you're a jeweler perfecting a custom piece or an industrial refiner optimizing high-volume throughput, KINTEK's advanced induction furnace solutions are engineered to scale with you. Leveraging our exceptional R&D and in-house manufacturing, we provide a diverse range of high-temperature furnaces—including custom configurations—to precisely meet your unique capacity, safety, and purity requirements.

Contact our experts today to discuss how we can tailor a high-efficiency melting solution for your specific goals.

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What is the output of an induction furnace? Achieve High-Purity, Uniform Molten Metal

- Why is the compact design of channel induction furnaces advantageous? Unlock Space & Energy Savings

- What are the three main components of a vacuum induction melting furnace? Key Systems for Pure Metal Production

- What is the role of shell mold heating in a vacuum induction furnace? Optimize Casting Flow & Integrity

- What are the key features and benefits of a Vacuum Induction Melting Furnace? Achieve High-Purity Metal Production

- What is the role of a laboratory-scale VIM furnace for carbide-free bainitic steel? High-Purity Ingot Development

- What is the primary role of a VIM furnace in T91 steel production? Ensure Ultra-Pure Heat-Resistant Alloys

- What are the primary industrial applications of induction furnaces? Unlock Efficient Metal Processing Solutions