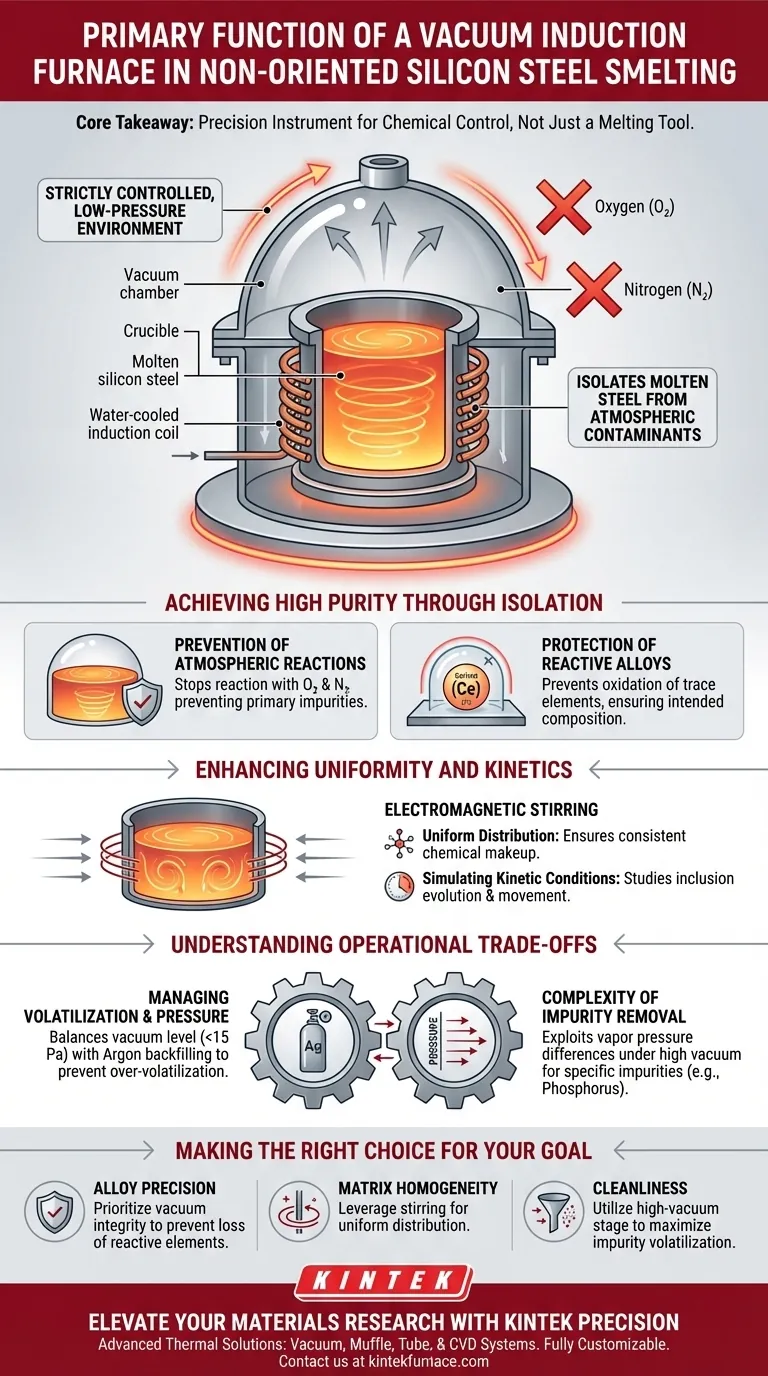

The primary function of a vacuum induction furnace in this context is to provide a strictly controlled, low-pressure environment that isolates molten steel from atmospheric contaminants. By utilizing induction heating within a vacuum, the furnace prevents the reaction of the melt with oxygen and nitrogen, ensuring a high-purity matrix and preventing the loss of reactive alloy components.

Core Takeaway: The vacuum induction furnace is not merely a melting tool; it is a precision instrument for chemical control. Its main value lies in eliminating atmospheric interference to protect trace elements (like rare earth cerium) and ensure the structural integrity of the non-oriented silicon steel matrix.

Achieving High Purity Through Isolation

Prevention of Atmospheric Reactions

The fundamental challenge in smelting non-oriented silicon steel is the material's susceptibility to contamination.

The vacuum induction furnace addresses this by creating a controlled low-pressure environment. This effectively stops the molten steel from reacting with atmospheric oxygen and nitrogen, which are the primary sources of impurities in standard smelting processes.

Protection of Reactive Alloy Components

Precise control over chemical composition is critical for experimental steel grades.

This furnace setup is specifically designed to protect trace alloy components, such as rare earth cerium. Without the vacuum environment, these sensitive elements would oxidize rapidly, altering the steel's intended composition and degrading its properties.

Enhancing Uniformity and Kinetics

Electromagnetic Stirring

Beyond simple melting, the furnace utilizes the physics of induction to improve the melt's quality.

The electromagnetic induction generates a stirring effect within the molten steel. This promotes the uniform distribution of alloy components, ensuring that the final ingot has a consistent chemical makeup throughout.

Simulating Kinetic Conditions

For experimental purposes, the physical behavior of the melt is just as important as its chemistry.

The stirring effect and controlled atmosphere simulate the necessary kinetic conditions for studying how inclusions (impurities) evolve within the steel. This allows researchers to analyze the formation and movement of non-metallic particles in a stable environment.

Understanding the Operational Trade-offs

Managing Volatilization and Pressure

While the vacuum environment protects the steel, it also introduces specific operational variables that must be managed.

Users must balance the vacuum level (often reducing pressure to below 15 Pa) with the need for inert gas backfilling (typically high-purity Argon). This prevents the over-volatilization of desirable elements while maintaining protection against oxidation.

Complexity of Impurity Removal

The system is highly effective at preventing oxidation, but removing existing impurities requires careful manipulation of pressure gradients.

For example, specific impurities like phosphorus can be removed by exploiting vapor pressure differences under high vacuum, but this requires precise thermal and pressure regulation to avoid losing the silicon base material.

Making the Right Choice for Your Goal

When employing a vacuum induction furnace for experimental smelting, your operational focus should shift based on your specific research objectives:

- If your primary focus is Alloy Precision: Prioritize the vacuum integrity to prevent the oxidation loss of reactive elements like Cerium or Titanium.

- If your primary focus is Matrix Homogeneity: Leverage the electromagnetic stirring capabilities to ensure uniform distribution of elements before casting.

- If your primary focus is Cleanliness: Utilize the high-vacuum stage to maximize the volatilization of gaseous impurities and separate non-metallic inclusions.

Ultimately, the vacuum induction furnace serves as the gatekeeper of material purity, transforming variable raw materials into a scientifically consistent silicon steel matrix.

Summary Table:

| Feature | Function in Silicon Steel Smelting | Primary Benefit |

|---|---|---|

| Vacuum Environment | Isolates melt from O2 and N2 | Prevents contamination and oxidation |

| Induction Heating | Precise thermal control | Protects reactive trace elements (e.g., Cerium) |

| Electromagnetic Stirring | Homogenizes molten steel | Ensures uniform alloy distribution |

| Pressure Regulation | Backfilling with high-purity Argon | Minimizes volatilization of critical elements |

| Kinetic Control | Simulates inclusion movement | Enables advanced study of material cleanliness |

Elevate Your Materials Research with KINTEK Precision

Unlock the full potential of your experimental smelting with KINTEK’s advanced thermal solutions. Backed by expert R&D and world-class manufacturing, KINTEK offers high-performance Vacuum, Muffle, Tube, and CVD systems—all fully customizable to meet the rigorous demands of non-oriented silicon steel production and beyond.

Whether you need to protect sensitive rare earth elements or achieve perfect matrix homogeneity, our furnaces provide the atmospheric control and reliability your lab requires.

Ready to optimize your high-temperature processes? Contact our technical experts today to discuss your unique project needs and discover how KINTEK can enhance your lab's efficiency.

Visual Guide

References

- Lei Zhao, Xiaoyang Fu. Effect of rare-earth Ce on the texture of non-oriented silicon steels. DOI: 10.1515/htmp-2022-0321

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What role does a vacuum induction melting furnace play in Fe-5%Mn-C alloys? Ensure Chemical Integrity and High Purity

- What is the principle of a vacuum induction melting furnace based on? Achieve High-Purity Metal Melting

- What role does sustainability play in the IGBT induction melting furnace market? A Key Driver for Modern Foundries

- What are the operational features of an IGBT induction melting furnace? Achieve Faster, Smarter, and More Efficient Metal Melting

- Why are induction furnaces considered environmentally friendly? Discover Clean, Efficient Heating Solutions

- What is the primary role of a vacuum induction furnace in the initial preparation of Fe–32Ni alloys?

- What causes the melting of the solid scrap in the arc furnace? Unlock Efficient Steel Production

- How does vacuum or protective atmosphere melting improve alloy composition uniformity? Achieve Precise Alloy Chemistry Control