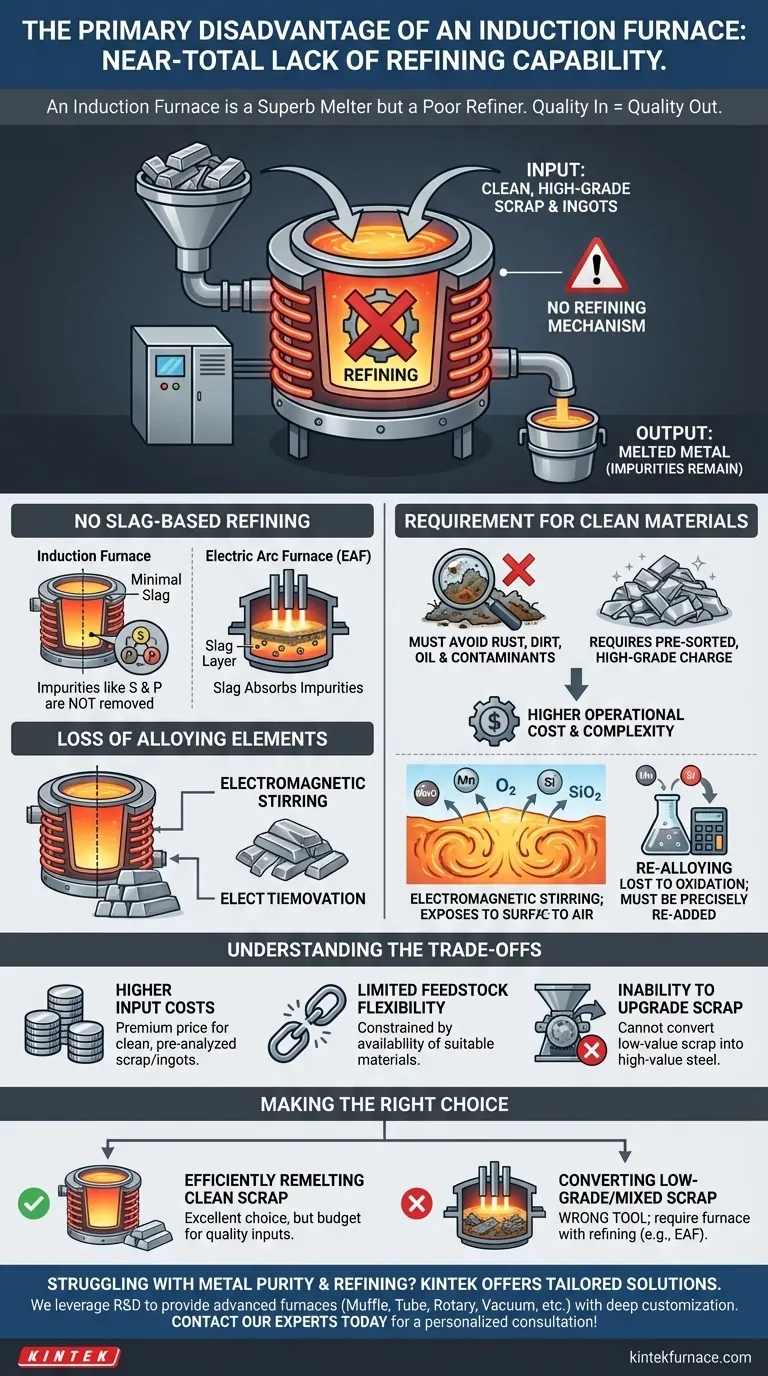

The primary disadvantage of an induction furnace is its near-total lack of refining capability. Unlike other furnace types, it cannot remove impurities from the input metal. This means the charge materials must be exceptionally clean and of a known chemical composition, and any elements lost to oxidation during the melt must be re-added.

An induction furnace is a superb melter but a poor refiner. Its core limitation is that the quality of the metal you produce is almost entirely dictated by the quality of the metal you put in, a classic "garbage in, garbage out" scenario.

The Challenge of Input-Dependent Quality

An induction furnace operates by using powerful magnetic fields to induce an electric current within the metal itself, causing it to heat and melt rapidly. While this process is incredibly efficient, it lacks the mechanisms necessary for metallurgical refining.

No Slag-Based Refining

In furnaces like an Electric Arc Furnace (EAF), a layer of slag is used to absorb impurities like sulfur and phosphorus from the molten metal. An induction furnace generates very little slag, leaving it with no practical way to remove these unwanted elements.

The chemistry of the charge material is effectively locked in. If you start with high-phosphorus scrap, you will end with high-phosphorus steel.

The Requirement for Clean Materials

Because the furnace cannot clean the metal, the charge must be free of excessive rust, dirt, oil, and non-metallic contaminants. Preparing and sourcing this high-grade scrap adds significant operational cost and complexity compared to processes that can handle lower-quality inputs.

Loss of Alloying Elements

The intense electromagnetic stirring inherent to induction melting, while excellent for homogenization, increases the molten metal's exposure to the atmosphere. This exposure leads to the oxidation and loss of valuable and easily oxidized alloying elements like manganese and silicon.

Operators must compensate for this "melt loss" by precisely calculating and adding back these expensive elements before pouring to meet final specifications.

Understanding the Trade-offs

The lack of refining is not just a technical detail; it creates a cascade of operational and financial trade-offs that must be managed carefully.

Higher Input Material Costs

The fundamental trade-off is performance for purity. To achieve the high efficiency and precise temperature control of an induction furnace, you must be willing to pay a premium for clean, pre-sorted, and analyzed scrap or pure ingots.

Limited Feedstock Flexibility

Your operation is constrained by the availability of suitable charge materials. You cannot simply switch to a cheaper, lower-grade scrap supply if your primary source becomes unavailable or too expensive without compromising the quality of your final product.

Inability to Upgrade Scrap Quality

An induction furnace is best thought of as a remelting tool, not a primary steelmaking vessel. It cannot take low-value, contaminated scrap and upgrade it into high-value, clean steel. Its role is to efficiently remelt material that is already at or near the desired final quality.

Making the Right Choice for Your Goal

Selecting the correct furnace technology depends entirely on your raw materials and your desired output.

- If your primary focus is efficiently remelting clean scrap or pre-alloyed ingots: An induction furnace is an excellent choice, but you must budget for high-quality inputs and compensate for alloy loss during the melt.

- If your primary focus is converting mixed, contaminated, or low-grade scrap into new steel: An induction furnace is the wrong tool; you require a furnace with refining capabilities, such as an Electric Arc Furnace (EAF).

Understanding this core limitation is the key to leveraging the induction furnace for its strengths while avoiding costly operational missteps.

Summary Table:

| Aspect | Key Limitation |

|---|---|

| Refining Capability | Cannot remove impurities like sulfur or phosphorus. |

| Charge Material | Requires exceptionally clean, high-grade scrap or ingots. |

| Element Loss | Alloying elements (e.g., manganese, silicon) are lost to oxidation. |

| Operational Cost | Higher input material costs and need for precise re-alloying. |

| Feedstock Flexibility | Limited to available high-quality materials; cannot upgrade low-grade scrap. |

Struggling with metal purity and refining challenges in your lab or production line? An induction furnace's limitations can be a major hurdle. At KINTEK, we leverage our exceptional R&D and in-house manufacturing to provide advanced furnace solutions tailored to your specific metallurgical needs. Whether you require the precise, clean melting of an induction system or the robust refining capabilities of other furnace types, our diverse product line—including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems—is backed by strong deep customization capabilities. Let us help you select or design the perfect furnace to meet your unique experimental and production goals. Contact our experts today for a personalized consultation!

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- How has vacuum smelting impacted the development of superalloys? Unlock Higher Strength and Purity

- What are some common applications of vacuum induction melting and casting (VIM&C)? Essential for Aerospace, Medical, and Nuclear Industries

- What role does a vacuum induction melting furnace play in Fe-5%Mn-C alloys? Ensure Chemical Integrity and High Purity

- Why is a Vacuum Induction Melting (VIM) furnace essential? Unlock Purity for Aerospace and Semiconductors

- What are the core functions of the High Vacuum Induction Melting (VIM) furnace? Optimize DD5 Superalloy Purification