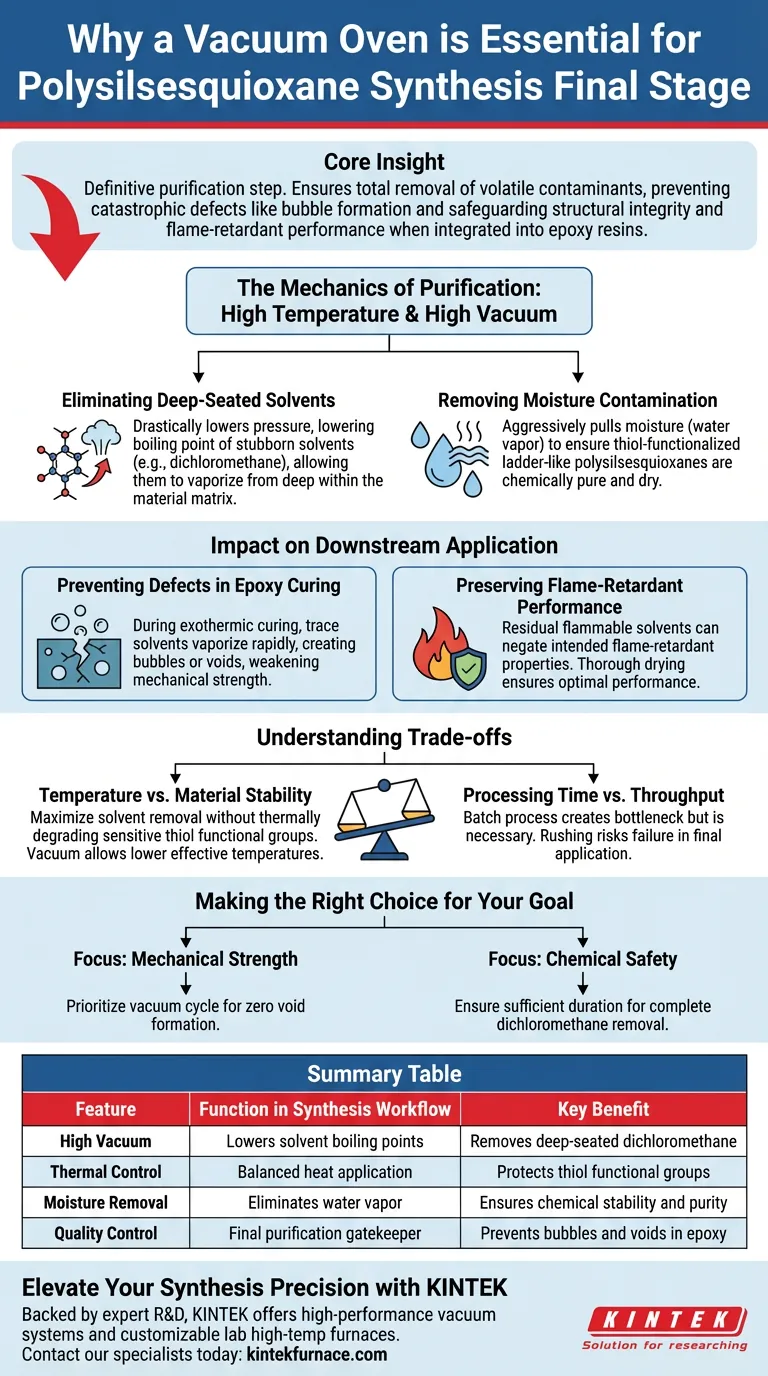

The vacuum oven serves as the definitive purification step in the polysilsesquioxane synthesis workflow, ensuring the total removal of volatile contaminants. It utilizes a combination of high temperature and high vacuum to extract trace amounts of residual solvents, specifically dichloromethane, and moisture from deep within the product's structure.

Core Insight: This step is not merely about drying; it is a critical quality control measure. By ensuring the material is completely solvent-free, the vacuum treatment prevents catastrophic defects—such as bubble formation—when the product is later integrated into epoxy resins, safeguarding both structural integrity and flame-retardant performance.

The Mechanics of Purification

Eliminating Deep-Seated Solvents

Standard drying methods are often insufficient for removing solvents trapped within complex molecular structures. The vacuum oven addresses this by drastically lowering the environmental pressure.

This pressure reduction lowers the boiling point of stubborn residual solvents like dichloromethane. This allows them to vaporize and escape from the material matrix at temperatures that might otherwise be ineffective under atmospheric pressure.

Removing Moisture Contamination

In addition to synthesis solvents, the product must be purged of moisture. Water vapor can interfere with downstream chemical reactions and compromise material stability.

The high-vacuum environment aggressively pulls moisture from the product, ensuring the thiol-functionalized ladder-like polysilsesquioxanes are chemically pure and dry before further processing.

Impact on Downstream Application

Preventing Defects in Epoxy Curing

One of the primary uses for this synthesized material is as an additive for epoxy resins. The curing process for epoxy is often exothermic (generating heat).

If trace solvents or moisture remain in the polysilsesquioxane, the heat of curing will cause them to vaporize rapidly. This gas expansion creates bubbles or voids within the cured resin, significantly weakening its mechanical strength and structural integrity.

Preserving Flame-Retardant Performance

The presence of residual organic solvents can actively work against the material's intended function. Solvents are often flammable and volatile.

Leaving these contaminants in the matrix can negate the flame-retardant properties of the polysilsesquioxane. Thorough vacuum drying ensures that the final additive performs exactly as designed without the interference of combustible residues.

Understanding the Trade-offs

Temperature vs. Material Stability

While the primary reference notes the use of "high temperature," this must be balanced carefully. The goal is to maximize solvent removal without thermally degrading the thiol functional groups.

Excessive heat can lead to the breakdown of these sensitive organic groups. The vacuum allows you to achieve drying efficiency at a lower effective temperature than would be required at standard atmospheric pressure, essentially protecting the chemical structure while cleaning it.

Processing Time vs. Throughput

Vacuum drying is a batch process that can create a bottleneck in production speed compared to continuous drying methods. However, this trade-off is necessary. Skipping or rushing this stage to save time introduces a high risk of failure during the final application phase.

Making the Right Choice for Your Goal

When optimizing your synthesis workflow, consider your end-use requirements:

- If your primary focus is Mechanical Strength: Prioritize the vacuum cycle to ensure zero void formation in the epoxy matrix, as bubbles are stress concentrators that lead to failure.

- If your primary focus is Chemical Safety: Ensure the drying duration is sufficient to remove dichloromethane completely to maintain optimal flame-retardant ratings.

The vacuum oven is the gatekeeper of quality, transforming a synthesized raw material into a reliable, high-performance additive.

Summary Table:

| Feature | Function in Synthesis Workflow | Key Benefit |

|---|---|---|

| High Vacuum | Lowers solvent boiling points | Removes deep-seated dichloromethane |

| Thermal Control | Balanced heat application | Protects thiol functional groups |

| Moisture Removal | Eliminates water vapor | Ensures chemical stability and purity |

| Quality Control | Final purification gatekeeper | Prevents bubbles and voids in epoxy |

Elevate Your Synthesis Precision with KINTEK

Don't let residual solvents compromise your material integrity. Backed by expert R&D and manufacturing, KINTEK offers high-performance vacuum systems and customizable lab high-temp furnaces—including Muffle, Tube, Rotary, and CVD systems—engineered for your unique synthesis needs.

Whether you are aiming for perfect mechanical strength or superior flame-retardant performance, our specialized equipment ensures your polysilsesquioxanes are pure, stable, and ready for high-end applications.

Ready to optimize your workflow? Contact our laboratory specialists today to find the perfect vacuum oven solution for your research.

Visual Guide

References

- Younghun Kim, Gyojic Shin. Influence of Thiol-Functionalized Polysilsesquioxane/Phosphorus Flame-Retardant Blends on the Flammability and Thermal, Mechanical, and Volatile Organic Compound (VOC) Emission Properties of Epoxy Resins. DOI: 10.3390/polym16060842

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

- 1200℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What are the advantages of using a Vacuum Reactor for bio-oil? Maximize Yield and Quality Through Pressure Control

- What maintenance advantages do multiple-chamber vacuum furnaces offer? Boost Uptime and Extend Lifespan

- What are the benefits of using drop-bottom quench furnaces? Achieve Superior Metallurgical Precision and Rapid Quenching

- How is brazing classified based on heating methods? Choose the Right Method for Your Application

- Why is a high-vacuum brazing furnace required for Kovar and stainless steel? Achieve Superior Oxide-Free Joints

- What are the benefits of using a vacuum drying oven for sensitive ceramic materials? Unlock Unmatched Material Purity

- What is the function of a vertical vacuum furnace in the purification of Rubidium Chloride? Achieve High Purity Yields

- Why is a vacuum arc-melting furnace preferred for Co-Ti-V quaternary superalloys? Ensure Purity & High-Temp Precision