The primary advantage of a Vacuum Reactor is its ability to significantly increase both the yield and quality of bio-oil compared to atmospheric systems. By operating under negative pressure, these reactors alter the physical environment of the pyrolysis process, facilitating the rapid removal of volatile products from high heat. This prevents the degradation of valuable compounds, leading to a superior liquid end-product.

The core operational principle is the lowering of vapor pressure. By allowing volatile substances to escape the heat zone rapidly, a Vacuum Reactor minimizes secondary cracking reactions, directly resulting in higher liquid yields and a higher-quality bio-oil.

The Mechanism of Action

Utilizing Negative Pressure

Vacuum reactors differ from atmospheric systems by employing a mechanical pump to generate negative pressure.

This reduction in pressure significantly lowers the vapor pressure of the pyrolysis products inside the reactor.

Accelerating Volatile Escape

The lowered vapor pressure creates a physical environment where volatile substances can vaporize and move more freely.

This allows these substances to escape the high-temperature zone rapidly, rather than lingering in the heat as they might in an atmospheric reactor.

Prevention of Chemical Degradation

Minimizing Secondary Cracking

The most critical technical benefit of this rapid escape is the reduction of secondary cracking.

Secondary cracking occurs when vapors remain exposed to high heat for too long, breaking down further into non-condensable gases or char.

By evacuating vapors quickly, the Vacuum Reactor preserves the integrity of the primary pyrolysis products.

Tangible Production Benefits

Increased Liquid Yield

Because fewer vapors degrade into unwanted gases, a larger percentage of the biomass is recovered as liquid.

The suppression of secondary cracking directly translates to a higher volume of bio-oil production.

Enhanced Bio-oil Quality

The speed of the process preserves the chemical structure of the oil.

Because the volatile fractions are removed before they can degrade, the resulting bio-oil exhibits enhanced overall quality compared to oil produced in atmospheric conditions.

Understanding the Operational Context

Reliance on Mechanical Systems

It is important to note that these advantages are dependent on active mechanical intervention.

The system relies entirely on the mechanical pump to generate the necessary negative pressure.

The benefits of yield and quality are strictly tied to the pump's ability to maintain this specific physical environment throughout the process.

Making the Right Choice for Your Goal

When deciding between a Vacuum Reactor and an atmospheric alternative, focus on your specific production targets.

- If your primary focus is Maximizing Output: The Vacuum Reactor is the optimal choice because it prevents potential liquid product from being lost as gas through secondary cracking.

- If your primary focus is Product Quality: The rapid removal of volatiles ensures a cleaner chemical profile, making the Vacuum Reactor superior for high-grade applications.

By controlling pressure, you effectively control the chemical destiny of your bio-oil.

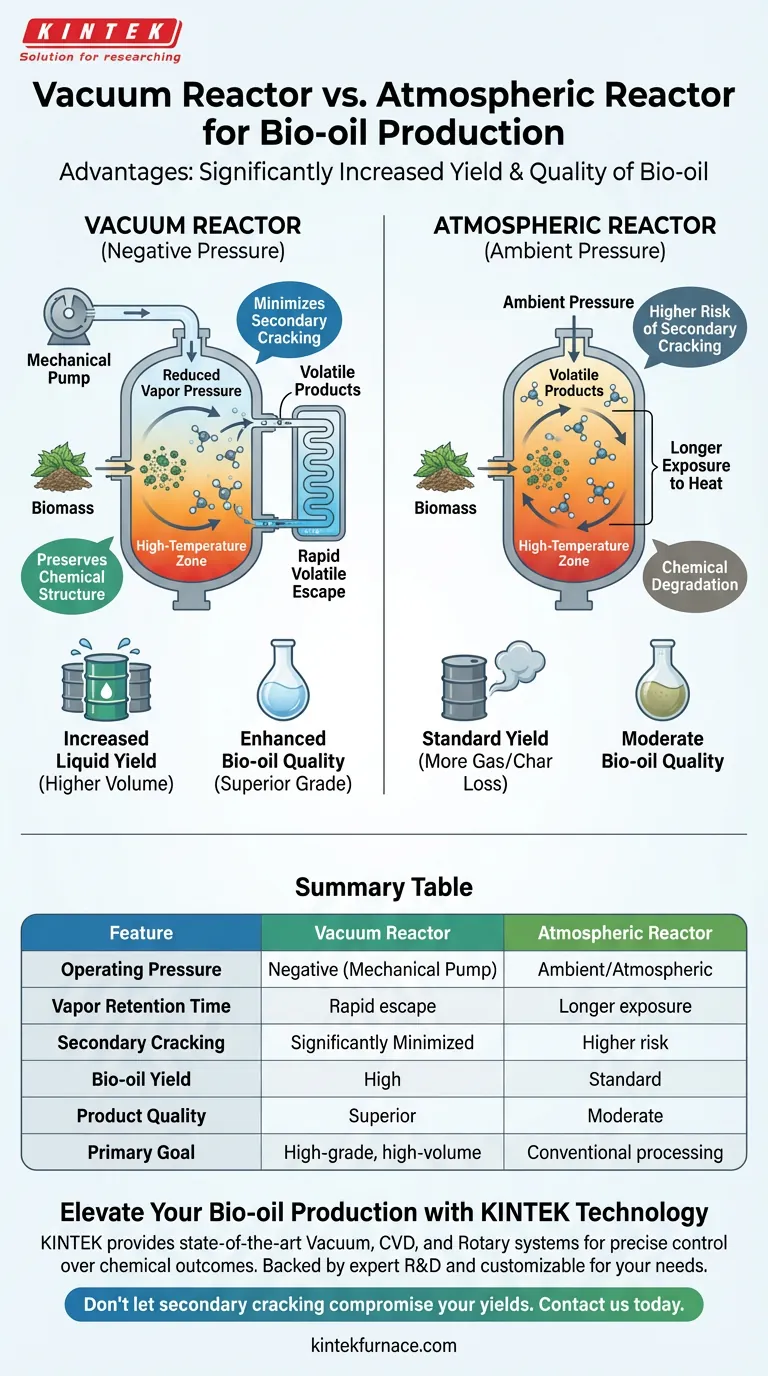

Summary Table:

| Feature | Vacuum Reactor | Atmospheric Reactor |

|---|---|---|

| Operating Pressure | Negative (Mechanical Pump) | Ambient/Atmospheric |

| Vapor Retention Time | Rapid escape from heat zone | Longer exposure to heat |

| Secondary Cracking | Significantly Minimized | Higher risk of degradation |

| Bio-oil Yield | High (Less gas/char loss) | Standard |

| Product Quality | Superior (Preserved chemical structure) | Moderate |

| Primary Goal | High-grade, high-volume production | Conventional processing |

Elevate Your Bio-oil Production with KINTEK Technology

Ready to transform your pyrolysis results? KINTEK provides state-of-the-art Vacuum, CVD, and Rotary systems designed to give you precise control over your chemical outcomes. Backed by expert R&D and manufacturing, our high-temperature lab furnaces are fully customizable to meet your unique research or production needs.

Don't let secondary cracking compromise your yields. Contact us today to find the perfect reactor for your lab and experience the KINTEK advantage in material science.

Visual Guide

References

- Ana B. Cuevas, M.P. Dorado. An Overview of Pyrolysis as Waste Treatment to Produce Eco-Energy. DOI: 10.3390/en17122852

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Sintering and Brazing Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What is the primary function of a high-pressure vacuum brazing furnace? Achieve Stronger Alloy Bonds

- What are the key requirements for a vacuum tempering furnace's cooling system? Ensure Precise Control for Superior Metallurgical Results

- How do continuous vacuum furnaces contribute to metal annealing and hardening? Achieve Superior Metallurgical Purity

- Why is a high-precision vacuum heat treatment furnace necessary for GCr15 specimens? Ensure Reliable Data Accuracy

- What materials can be processed using a vacuum sintering furnace? Unlock High-Purity Processing for Reactive Materials

- What are the applications of high-temperature vacuum sintering furnaces? Essential for Aerospace, Electronics, and Medical Materials

- What is the purpose of setting a mid-temperature dwell stage? Eliminate Defects in Vacuum Sintering

- How does a vacuum sintering furnace work? Unlock High-Purity Material Processing