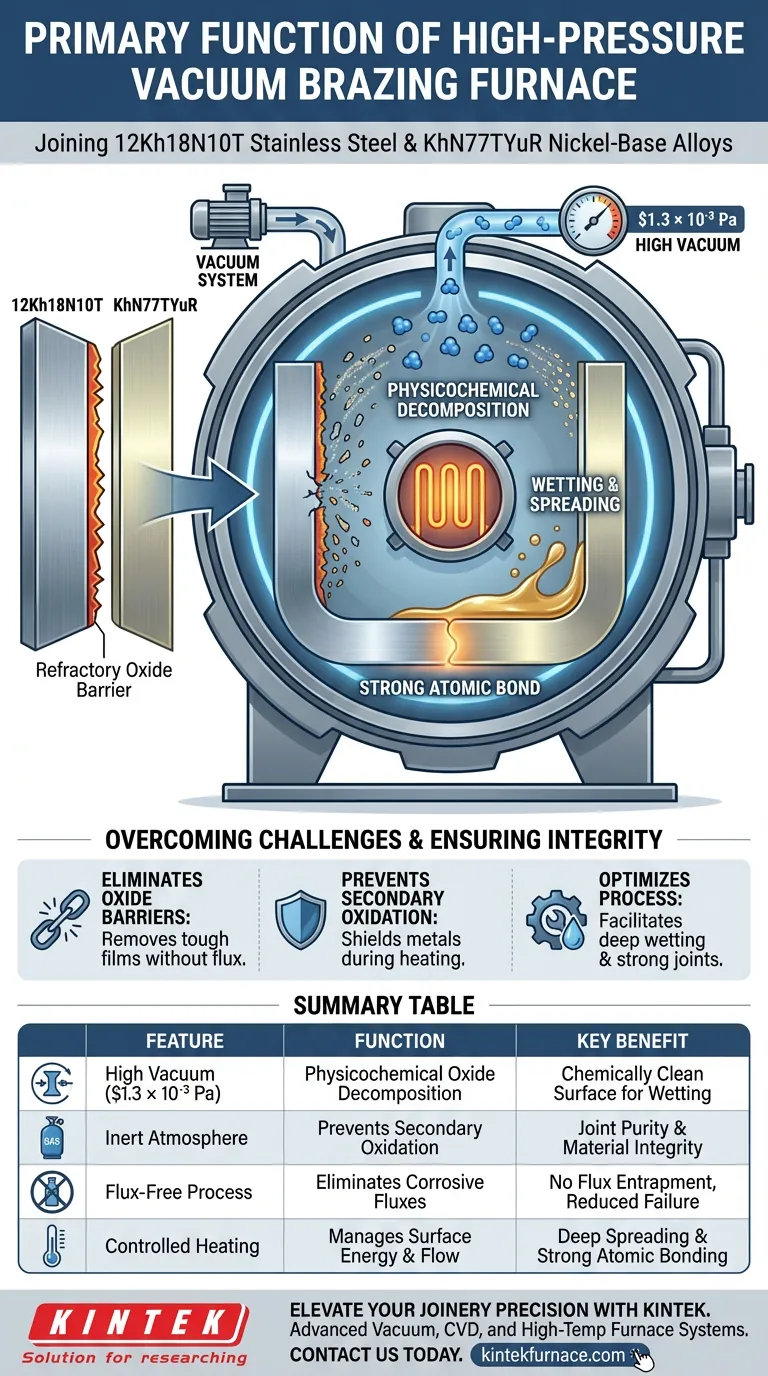

The primary function of a high-pressure vacuum brazing furnace is to create a controlled environment that actively removes refractory oxide films from metal surfaces while preventing new oxidation. By maintaining a high vacuum level, typically around $1.3 \times 10^{-3}$ Pa, the furnace facilitates the physicochemical decomposition of these surface oxides at elevated temperatures. This process is essential for joining dissimilar metals like 12Kh18N10T stainless steel and KhN77TYuR nickel-base alloys, as it ensures the chemically clean surface necessary for the filler metal to wet the joint and form a reliable atomic bond.

Joining complex alloys requires more than just heat; it requires a pristine surface environment. The vacuum furnace effectively acts as a cleaning agent, stripping away oxide barriers to ensure complete wetting and preventing the contamination that leads to weak interface bonds.

Overcoming the Surface Oxide Barrier

The Challenge of Refractory Oxides

Alloys such as 12Kh18N10T and KhN77TYuR naturally form tough, refractory oxide films on their surfaces.

These films act as a barrier, preventing the brazing filler metal from making direct contact with the base metal substrate. Without removing them, a strong metallurgical bond is impossible.

Physicochemical Decomposition

The vacuum furnace solves this by maintaining a pressure low enough (high vacuum) to facilitate physicochemical decomposition.

At high temperatures and low pressures ($1.3 \times 10^{-3}$ Pa), the chemical stability of the oxide film is compromised. The oxides essentially break down or dissociate, leaving behind a clean, active metal surface.

Elimination of Flux

Because the vacuum environment removes oxides thermally and chemically, there is no need for corrosive chemical fluxes.

This results in a cleaner process that eliminates the risk of flux entrapment inside the joint, which is a common failure point in conventional brazing.

Ensuring Joint Integrity During Heating

Preventing Secondary Oxidation

Heating metals to brazing temperatures in the presence of even trace amounts of oxygen causes rapid "secondary" oxidation.

The vacuum environment removes oxygen from the heating chamber, shielding the substrates and the filler metal from reacting with the atmosphere. This protection is critical throughout the entire heating cycle to maintain the purity of the materials.

Facilitating Wetting and Spreading

Once the oxide film is decomposed and secondary oxidation is blocked, the surface energy of the base metal increases.

This allows the molten filler metal to flow freely, wetting the surface completely and spreading evenly into the joint gap. This deep spreading is what creates the necessary atomic bond at the interface of the dissimilar metals.

Operational Constraints and Considerations

Dependency on Vacuum Level

The success of this process is entirely dependent on maintaining the specific vacuum level (e.g., $1.3 \times 10^{-3}$ Pa).

If the pressure rises even slightly above this threshold, the physicochemical decomposition of the oxides may not occur. This results in poor wetting and a weak joint, rendering the process ineffective.

Degassing Effects

While beneficial, the vacuum also induces a degassing effect, pulling volatile impurities out of the metal.

This generally improves hardness and quality, but it requires precise control to ensure that essential alloying elements are not vaporized along with the impurities.

Making the Right Choice for Your Project

To ensure high-quality joints between stainless steel and nickel-base alloys, apply these principles:

- If your primary focus is Bond Strength: Ensure your furnace can maintain the specific vacuum level ($1.3 \times 10^{-3}$ Pa) required to decompose the refractory oxides specific to your alloy combination.

- If your primary focus is Material Purity: Prioritize a system with rigorous leak detection to prevent secondary oxidation and eliminate the need for chemical fluxes.

By controlling the vacuum environment, you transform the furnace from a simple heater into a precision surface-preparation tool, guaranteeing the structural integrity of your assembly.

Summary Table:

| Feature | Function in Brazing Process | Key Benefit |

|---|---|---|

| High Vacuum ($1.3 \times 10^{-3}$ Pa) | Facilitates physicochemical decomposition of oxides | Creates a chemically clean surface for wetting |

| Inert Atmosphere | Prevents secondary oxidation during heating | Ensures joint purity and material integrity |

| Flux-Free Process | Eliminates the need for corrosive chemical fluxes | Removes risk of flux entrapment and joint failure |

| Controlled Heating | Manages surface energy and filler flow | Enables deep spreading and strong atomic bonding |

Elevate Your Joinery Precision with KINTEK

Don’t let refractory oxides compromise your critical assemblies. Backed by expert R&D and manufacturing, KINTEK offers advanced Vacuum, CVD, and High-Temp Furnace systems specifically designed for the rigorous demands of joining dissimilar metals like stainless steel and nickel-base alloys. Our customizable solutions provide the precise pressure control and thermal stability needed for flawless brazing results.

Ready to optimize your brazing process? Contact us today to discuss your unique needs!

Visual Guide

References

- S.V. Maksymova, P.V. Kovalchuk. Brazing stainless steel with high chromium nickel alloy. DOI: 10.21203/rs.3.rs-7259392/v1

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering and Brazing Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What is a vacuum furnace used for? Achieve Purity and Precision in High-Temp Processing

- How does vacuum heat treatment improve mechanical properties of metals? Enhance Strength and Durability

- What is the heat treatment in a vacuum furnace? Achieve Superior Metallurgical Properties

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today

- What is the process of vacuum heat treatment? Achieve Superior Metallurgical Properties