A Vacuum Drying Oven is the superior choice for Transition Metal Phosphates (TMPs) because it fundamentally changes the physics of evaporation to protect the material's delicate structure. Unlike standard ovens that rely on high heat, a vacuum oven lowers the boiling point of solvents like water or ethanol, allowing them to vaporize rapidly at low temperatures. This prevents the collapse of fine pores and ensures the material retains the high surface area necessary for optimal performance.

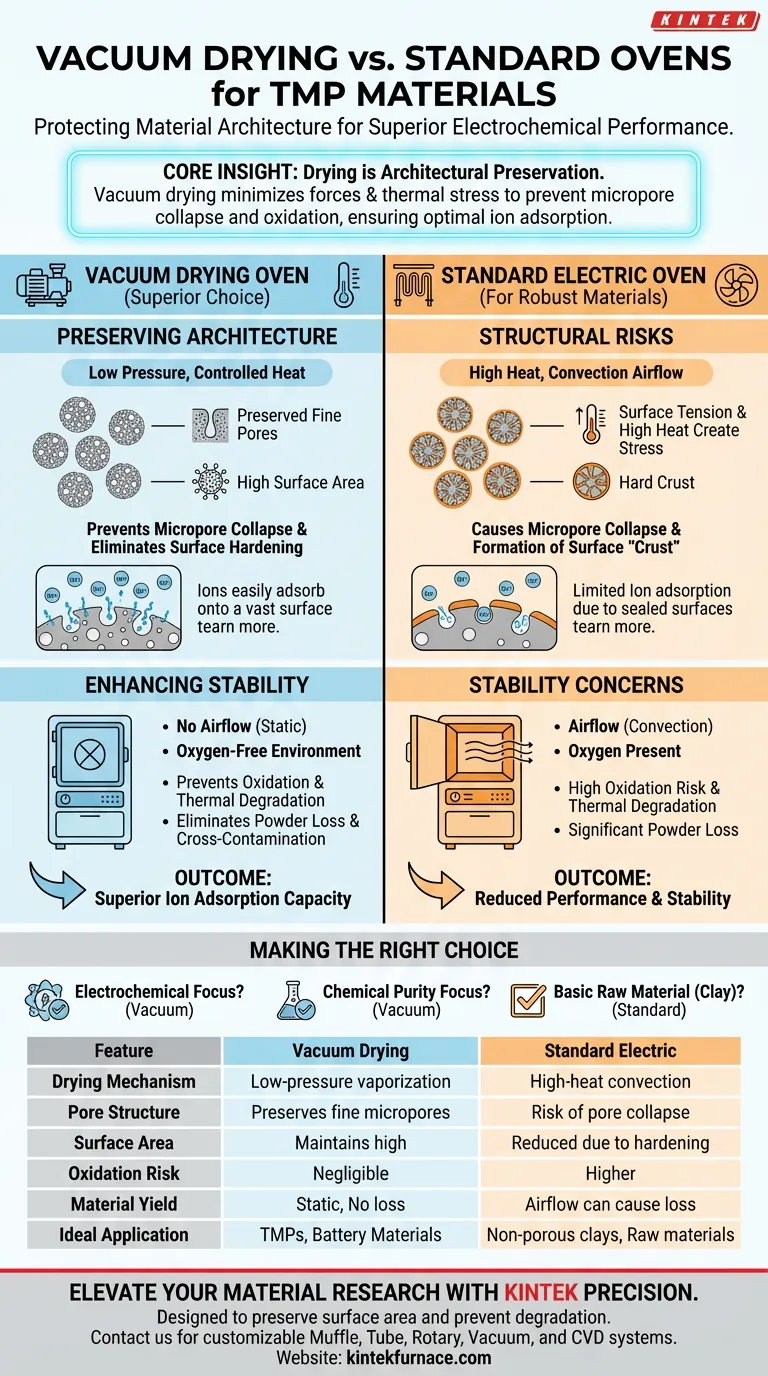

Core Insight For porous materials like TMPs, the drying process is not just about removing liquid; it is about architectural preservation. Vacuum drying minimizes surface tension forces and thermal stress, preventing micropore collapse and oxidation to ensure the final product exhibits superior ion adsorption capacity.

Preserving Material Architecture

Preventing Micropore Collapse

The most critical advantage of a vacuum drying oven is its ability to preserve the fine pore structure of TMPs. Standard atmospheric drying relies on heat, which can create high surface tension within the pores as the solvent evaporates.

This tension frequently causes micropore collapse, effectively sealing off the internal surface area of the material. By lowering the pressure, the vacuum oven facilitates evaporation with significantly reduced physical stress on the material's framework.

Maintaining Specific Surface Area

The electrochemical performance of TMPs is directly linked to their specific surface area. A higher surface area allows for better interaction between the electrode material and the electrolyte.

Vacuum drying protects the material's mesoporous characteristics. This preservation directly translates to superior ion adsorption capacity during electrochemical testing, a key metric for battery performance.

Eliminating Surface Hardening

In standard convective drying, the outer surface of the material often dries faster than the core. This can form a hard "crust" that traps moisture inside the porous agglomerates.

Vacuum environments prevent this phenomenon known as surface hardening. This ensures the thorough removal of residual moisture from deep within the particle structure, enhancing the quality stability of the precursor powder.

Enhancing Chemical and Physical Stability

Preventing Oxidation and Degradation

TMPs and their additives can be heat-sensitive. The vacuum environment lowers the required processing temperature, protecting active materials and ceramic additives from thermal degradation.

Furthermore, the vacuum chamber effectively excludes oxygen. This prevents surface oxidation of the ultra-fine powders, ensuring the chemical composition remains pure and stable throughout the process.

Reducing Physical Material Loss

Standard electric ovens rely on air convection (fans) to distribute heat. For ultra-fine powders like TMPs, this airflow can disturb the sample and cause powder loss.

Vacuum drying is a static process that eliminates airflow disturbances. This not only maximizes yield but also eliminates the risk of cross-contamination that can occur via air convection in standard ovens.

Understanding the Trade-offs

When Standard Ovens Suffice

It is important to acknowledge that standard constant temperature ovens have a place in material science. For example, when processing robust raw materials like clays (illite or kaolinite), a standard oven at 40°C is effective.

It can remove physically adsorbed water without damaging the structural water of the minerals. However, for advanced engineered materials like TMPs where pore architecture is the priority, the standard oven lacks the precision and environmental control required.

Making the Right Choice for Your Goal

- If your primary focus is electrochemical performance: Choose the Vacuum Drying Oven to maximize specific surface area and prevent micropore collapse.

- If your primary focus is chemical purity: Choose the Vacuum Drying Oven to eliminate oxidation risks and thermal degradation of heat-sensitive additives.

- If your primary focus is basic raw material preparation: A standard oven may suffice for removing surface moisture from non-porous, robust clays where structural preservation is less critical.

By selecting the vacuum drying method, you are not merely drying a sample; you are engineering the physical stability required for high-performance energy storage.

Summary Table:

| Feature | Vacuum Drying Oven | Standard Electric Oven |

|---|---|---|

| Drying Mechanism | Low-pressure vaporization | High-heat convection |

| Pore Structure | Preserves fine micropores | Risk of pore collapse |

| Surface Area | Maintains high surface area | Reduced due to hardening |

| Oxidation Risk | Negligible (Oxygen-free) | Higher due to airflow |

| Material Yield | Static (No powder loss) | Airflow can cause loss |

| Ideal Application | TMPs, Battery Materials | Non-porous clays, Raw materials |

Elevate Your Material Research with KINTEK Precision

Don't compromise the architecture of your transition metal phosphates. KINTEK’s advanced Vacuum Drying Ovens are designed to preserve specific surface area and prevent thermal degradation, ensuring your samples achieve maximum ion adsorption capacity.

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems, all customizable to meet your laboratory's unique high-temperature and atmospheric requirements.

Ready to optimize your drying process? Contact us today to discuss your custom solution!

Visual Guide

References

- Muhammad Ramzan Abdul Karim, Y Haroon. Elucidating Electrochemical Energy Storage Performance of Unary, Binary, and Ternary Transition Metal Phosphates and their Composites with Carbonaceous Materials for Supercapacitor Applications. DOI: 10.33961/jecst.2024.00024

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Sintering and Brazing Furnace

People Also Ask

- What processes can vacuum furnaces perform? Unlock High-Purity Thermal Processing for Superior Materials

- Why are the materials used in vacuum furnace construction critical? Ensure Peak Performance and Purity

- How does vacuum degree affect the sintering atmosphere? Optimize Material Purity and Performance

- How does a vacuum drying oven assist in maintaining the high specific surface area of (Y0.2La0.2Nd0.2Gd0.2Sm0.2)CoO3 nanofibers?

- Why has vacuum heat treatment technology gained widespread use? Achieve Superior Material Control and Performance

- What factors should be considered when choosing between a box furnace and a vacuum furnace? Key Insights for Your Lab

- What was the traditional insulation setup in vacuum furnaces, and how has it changed? Discover the Modern All-Felt System

- What temperature range can most vacuum furnace systems operate within? Discover the Capabilities for Your Process