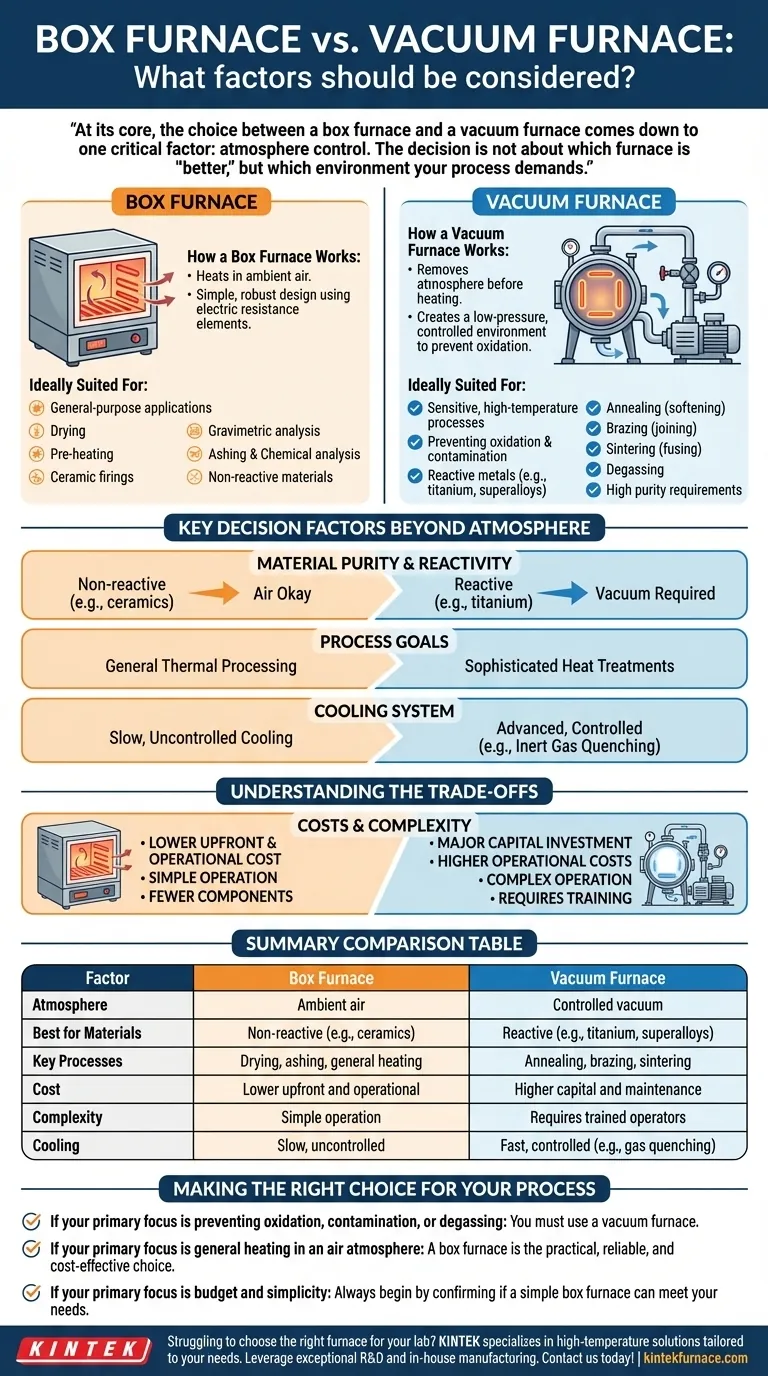

At its core, the choice between a box furnace and a vacuum furnace comes down to one critical factor: atmosphere control. A box furnace heats materials in ambient air, making it suitable for general-purpose applications. A vacuum furnace first removes the atmosphere, creating a controlled environment that is essential for preventing oxidation and contamination in sensitive, high-temperature processes.

The decision is not about which furnace is "better," but which environment your process demands. If your material cannot tolerate exposure to air at high temperatures, a vacuum furnace is required. For all other heating tasks, a simpler and more cost-effective box furnace is the appropriate choice.

The Fundamental Difference: Atmosphere

The primary distinction between these two technologies is the environment in which the material is heated. Understanding this is the first step in making the correct decision.

How a Box Furnace Works

A box furnace, often called a muffle furnace, is a straightforward heating chamber. It uses electric resistance heating elements to heat the internal space through radiation and convection.

The material inside is exposed to the ambient air within the furnace. This design is simple, robust, and easy to operate, making it ideal for processes where an air atmosphere is acceptable or even required.

How a Vacuum Furnace Works

A vacuum furnace is a more complex system. Before heating begins, a vacuum system removes the air and other gases from the sealed chamber. Heating is then performed in this low-pressure, controlled environment.

This prevents oxidation, protects the material's surface finish, and can even pull trapped gases out of the material itself (degassing). It is essential for processes involving reactive metals or requiring high levels of purity.

Key Decision Factors Beyond Atmosphere

Once you understand the atmospheric difference, you can evaluate your process against several other key factors to finalize your choice.

Material Purity and Reactivity

This is the most important application driver. Metals like titanium or specific superalloys will react aggressively with oxygen and nitrogen at high temperatures, becoming brittle and unusable. These reactive materials mandate the use of a vacuum furnace.

For ceramics, less reactive metals, or processes like ashing and chemical analysis, a box furnace is perfectly suitable.

Required Temperature Range

Both furnace types can achieve very high temperatures. The critical question is not just "how hot?" but "how hot in what atmosphere?" Ensure the furnace you select can reach your target temperature while providing the necessary environmental control.

Process Goals: Annealing, Brazing, Sintering vs. General Heating

A vacuum furnace is specifically designed for sophisticated heat treatments. Processes like annealing (softening metal), brazing (joining metals with a filler), and sintering (fusing powders) often require a vacuum to ensure material integrity and joint strength.

A box furnace is the workhorse for general thermal processing, including drying, pre-heating, certain ceramic firings, and gravimetric analysis.

Cooling System Requirements

Vacuum furnaces often incorporate advanced, controlled cooling systems, such as inert gas quenching. This allows for rapid and uniform cooling, which is a critical phase of many heat treatment specifications.

Box furnaces typically cool down slowly along with the furnace chamber once power is cut, which is a less controlled process.

Understanding the Trade-offs

Capability comes at a cost. A vacuum furnace offers superior process control, but this is balanced by significant increases in complexity and expense.

Upfront and Operational Costs

A box furnace is significantly less expensive to purchase, operate, and maintain. Its design is simple, with fewer components that can fail.

A vacuum furnace represents a major capital investment. It also has higher ongoing costs related to the vacuum pump system, seals, and higher energy consumption.

Operational Complexity and Control

Operating a box furnace is often as simple as setting a temperature and a time. They are forgiving and require minimal training.

A vacuum furnace is a complex piece of equipment. Operators must be trained to manage vacuum cycles, monitor for leaks, and understand the interplay between pressure, temperature, and time to ensure process quality and safety.

Production Capacity and Automation

Both furnace types are available in a wide range of sizes, from small laboratory units to large industrial production systems. However, the sophisticated process control inherent in vacuum furnaces lends itself well to full automation, ensuring repeatable, high-quality results for critical components.

Making the Right Choice for Your Process

Base your decision on your non-negotiable process requirements, not on the furnace technology itself.

- If your primary focus is preventing oxidation, contamination, or degassing: You must use a vacuum furnace to protect your material and ensure a successful outcome.

- If your primary focus is general heating in an air atmosphere: A box furnace is the more practical, reliable, and cost-effective choice for tasks like ashing, drying, or pre-heating non-reactive materials.

- If your primary focus is budget and simplicity: Always begin by confirming if a simple box furnace can meet your needs before committing to the expense and complexity of a vacuum system.

By first defining your required processing atmosphere, you can confidently select the furnace that provides the right capability at the right cost.

Summary Table:

| Factor | Box Furnace | Vacuum Furnace |

|---|---|---|

| Atmosphere | Ambient air | Controlled vacuum |

| Best for Materials | Non-reactive (e.g., ceramics) | Reactive (e.g., titanium, superalloys) |

| Key Processes | Drying, ashing, general heating | Annealing, brazing, sintering |

| Cost | Lower upfront and operational | Higher capital and maintenance |

| Complexity | Simple operation | Requires trained operators |

| Cooling | Slow, uncontrolled | Fast, controlled (e.g., gas quenching) |

Struggling to choose the right furnace for your lab? KINTEK specializes in high-temperature solutions tailored to your needs. Leveraging exceptional R&D and in-house manufacturing, we offer advanced furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure precise alignment with your unique experimental requirements, enhancing efficiency and results. Contact us today to discuss how we can support your process with reliable, cost-effective equipment!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- What additional processes can a vacuum heat treatment furnace carry out? Unlock Advanced Material Processing

- What does a vacuum furnace do? Achieve Superior Material Processing in a Pure Environment

- What is the purpose of setting a mid-temperature dwell stage? Eliminate Defects in Vacuum Sintering

- What are the benefits of using a high-temperature vacuum furnace for the annealing of ZnSeO3 nanocrystals?

- How does a vacuum heat treatment furnace prevent contamination? Ensure Purity in High-Temperature Processes