The use of a vacuum drying oven is essential for securing the structural and chemical integrity of electrocatalytic electrode sheets. It serves a dual purpose: it lowers the boiling point of solvents like isopropanol and water to facilitate deep evaporation at safe temperatures, and it creates an anaerobic environment to effectively prevent the oxidation of the catalytic material.

By decoupling temperature from evaporation rates, vacuum drying allows for the complete removal of solvents from deep within the electrode pores without thermally degrading the catalyst. This ensures a dense, uniform coating and unobstructed pathways for charge conduction.

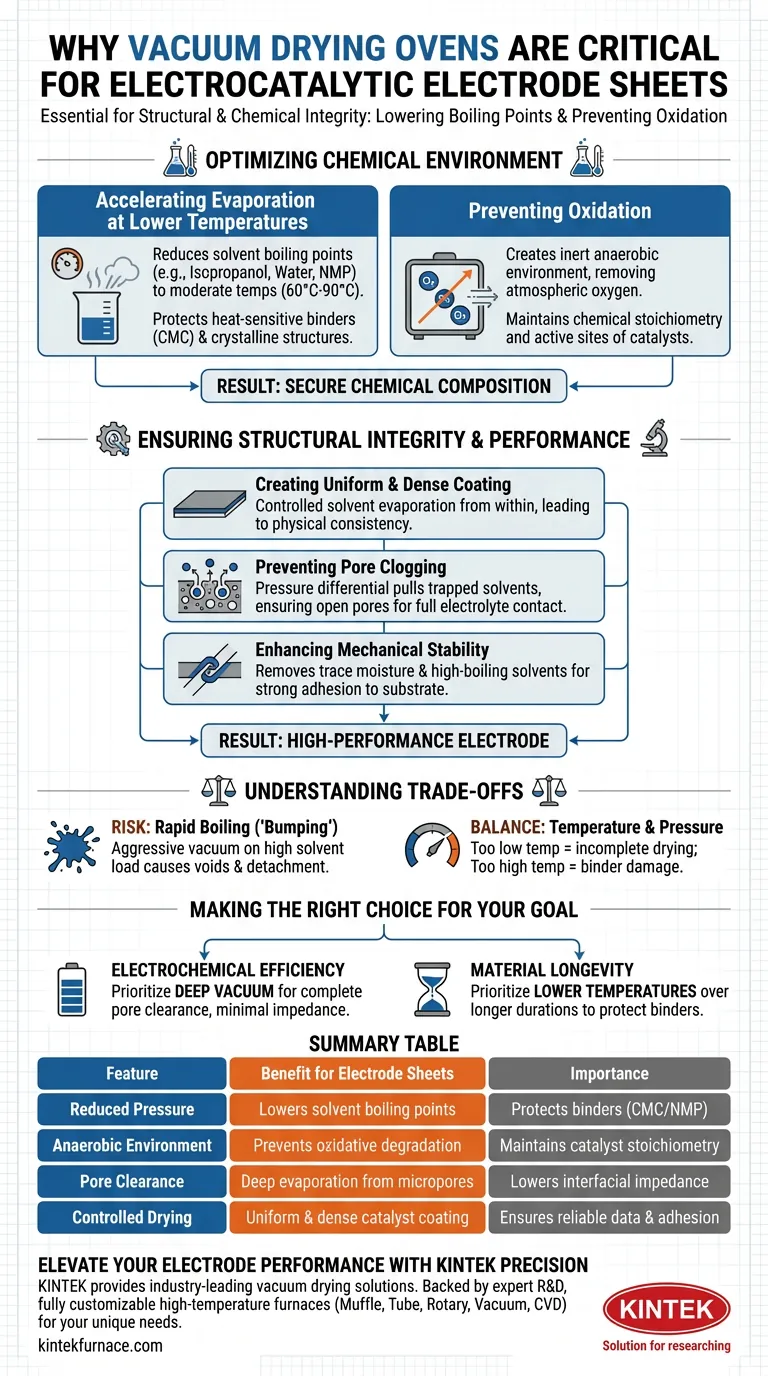

Optimizing the Chemical Environment

Accelerating Evaporation at Lower Temperatures

The primary function of the vacuum oven is to significantly reduce the boiling point of solvents.

By lowering the pressure, solvents such as isopropanol, water, and NMP can evaporate rapidly at moderate temperatures (e.g., 60 °C to 90 °C) rather than requiring high heat.

This protects heat-sensitive components, such as binders (like CMC) or delicate crystalline structures, from thermal degradation while ensuring the slurry dries completely.

Preventing Oxidation

Standard thermal drying exposes the catalyst to atmospheric oxygen, which can alter the chemical composition of the active material.

The vacuum environment effectively removes air from the chamber, creating an inert atmosphere that prevents oxidative degradation during the drying process.

This is critical for maintaining the specific stoichiometry of the catalyst, ensuring that the active sites created during synthesis remain chemically active for electrochemical testing.

Ensuring Structural Integrity and Performance

Creating a Uniform and Dense Coating

Vacuum drying promotes a more controlled consolidation of the catalyst layer onto the substrate (such as graphite foil).

As solvents evaporate evenly from within the material matrix, the catalyst layer forms a uniform and dense coating.

This physical consistency is vital for ensuring reliable experimental data, as variations in coating density can lead to erratic current density readings.

Preventing Pore Clogging

A major failure point in electrode preparation is the retention of residual solvents within the micropores of the material.

The vacuum exerts a pressure differential that pulls trapped solvent molecules out of these pores, preventing clogging.

Open pores are essential for ensuring full contact between the electrolyte and the active material, thereby reducing interfacial impedance and maximizing efficiency.

Enhancing Mechanical Stability

Deep drying under vacuum ensures a strong physical bond between the active material, the binder, and the current collector.

By removing trace moisture and high-boiling point solvents that might act as plasticizers or barriers, the process enhances the mechanical adhesion of the coating.

This prevents the material from detaching or flaking off during fluid flushing or vigorous electrochemical reactions.

Understanding the Trade-offs

While vacuum drying is superior to ambient drying, it requires careful parameter control to avoid damaging the electrode.

The Risk of Rapid Boiling ("Bumping")

If the vacuum is applied too aggressively while the solvent load is still high, the solvent may boil violently inside the coating.

This can cause the material to "bump" or splatter, creating voids in the coating or causing the catalyst to detach from the substrate entirely.

Balancing Temperature and Pressure

While vacuum allows for lower temperatures, setting the temperature too low may result in incomplete drying, leaving trace moisture that can cause electrolyte decomposition.

Conversely, excessively high temperatures, even under vacuum, can still damage organic binders or cause phase changes in specific composites.

Making the Right Choice for Your Goal

To maximize the performance of your electrocatalytic electrodes, tailor your drying parameters to your specific objectives:

- If your primary focus is Electrochemical Efficiency: Prioritize deep vacuum levels to ensure complete pore clearance, guaranteeing maximum electrolyte contact and minimal impedance.

- If your primary focus is Material Longevity: Prioritize lower temperatures (e.g., 60 °C) over longer durations to protect the binder structure and prevent oxidation of the active sites.

Correctly implemented, vacuum drying transforms a wet slurry into a high-performance electrode ready for rigorous testing.

Summary Table:

| Feature | Benefit for Electrode Sheets | Importance |

|---|---|---|

| Reduced Pressure | Lowers solvent boiling points | Protects heat-sensitive binders (CMC/NMP) |

| Anaerobic Environment | Prevents oxidative degradation | Maintains chemical stoichiometry of catalysts |

| Pore Clearance | Deep evaporation from micropores | Lowers interfacial impedance for better efficiency |

| Controlled Drying | Uniform & dense catalyst coating | Ensures reliable current density & mechanical adhesion |

Elevate Your Electrode Performance with KINTEK Precision

Don't let residual solvents or oxidation compromise your research. KINTEK provides industry-leading vacuum drying solutions specifically designed for sensitive electrochemical materials. Backed by expert R&D and manufacturing, we offer a comprehensive range of lab high-temperature furnaces—including Muffle, Tube, Rotary, Vacuum, and CVD systems—all fully customizable to meet your unique drying and synthesis requirements.

Ensure the structural integrity of your catalysts and achieve consistent experimental results with our precision-engineered equipment. Contact us today to find the perfect drying solution for your lab!

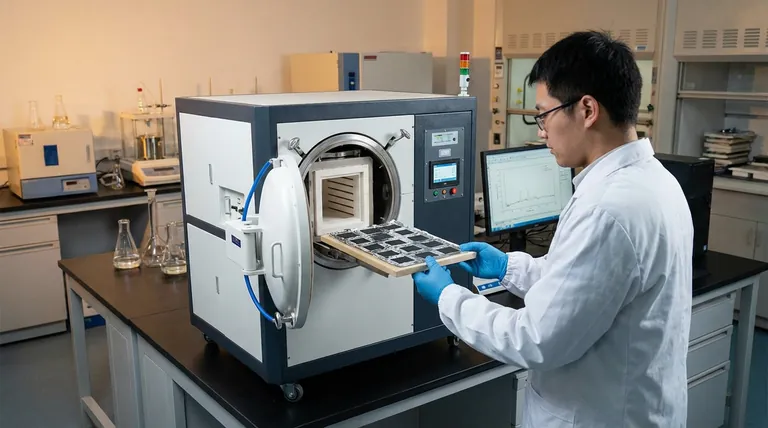

Visual Guide

References

- Ewa Mijowska, Klaudia Maślana. Highly Porous Carbon Flakes Derived from Cellulose and Nickel Phosphide Heterostructure towards Efficient Electrocatalysis of Oxygen Evolution Reaction. DOI: 10.3390/molecules29020352

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering and Brazing Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- What heat treatment processes can a vacuum furnace perform? Achieve Superior Control and Clean Results

- Why is a vacuum preheating furnace used for aluminum foam sandwich panels? Ensure High-Strength Metallic Bonding

- What is the hot zone in a vacuum furnace? Key Components and Performance Insights

- What are the required environmental conditions for operating a vacuum furnace? Ensure Safety and Optimal Performance

- How does a vacuum annealing furnace facilitate the purification of carbon nanofibers (CNF)? Achieve Ultra-High Purity

- What are the key material requirements for crucibles used in the vacuum distillation of aluminum-magnesium alloys? Ensure High-Purity Metal Separation

- What are the safety considerations when using nitrogen and argon in vacuum furnaces? Prevent Asphyxiation Risks in Your Lab

- Why is controlling sulfur levels beneficial for the removal of tin impurities? Optimize Vacuum Steelmaking Efficiency