A vacuum annealing furnace purifies carbon nanofibers (CNF) by subjecting them to a high-temperature heat treatment that physically desorbs impurities and corrects structural defects. Operating at 800°C for three hours under vacuum, this process refines the material after its initial washing phase, ensuring the final product is chemically pure and structurally sound.

The vacuum environment is the defining factor in this process; it allows for the high temperatures necessary to remove impurities and refine the carbon structure while strictly preventing the oxidation that would destroy the material in an open-air environment.

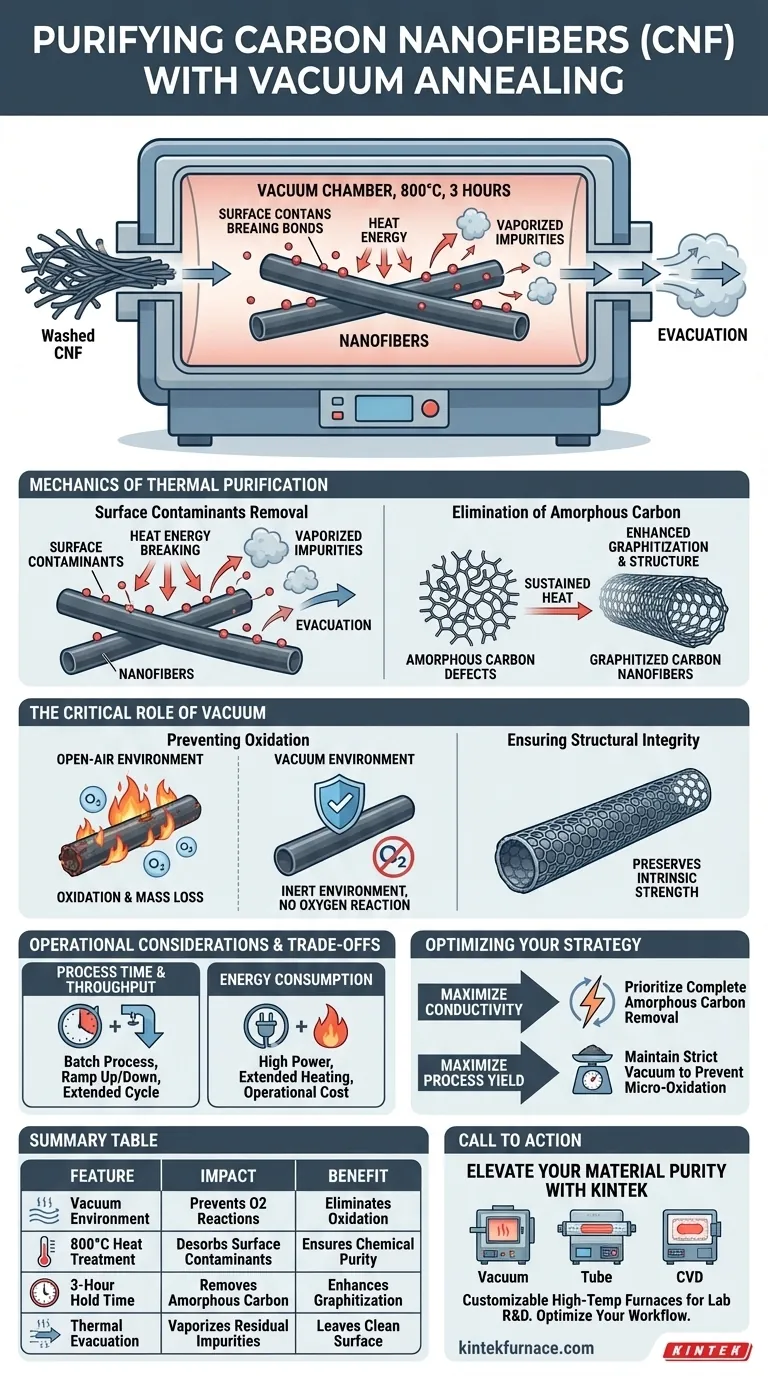

The Mechanics of Thermal Purification

Removal of Surface Contaminants

Even after initial washing, carbon nanofibers often retain physically adsorbed impurities. The vacuum annealing furnace addresses this by applying sustained thermal energy.

At 800°C, the bond between the fiber surface and these residual contaminants is broken. The impurities are effectively vaporized and evacuated from the chamber, leaving the carbon surface clean.

Elimination of Amorphous Carbon

A critical function of this treatment is the removal of amorphous carbon, a common defect where carbon atoms lack a crystalline structure. Amorphous carbon creates weak points and reduces the overall quality of the filler.

The three-hour heat treatment provides the energy required to eliminate these disordered carbon defects. This results in a higher degree of graphitization, ensuring the nanofibers possess the optimal tubular structure required for high-performance applications.

The Critical Role of the Vacuum Environment

Preventing Oxidation

Carbon materials are highly susceptible to oxidation when exposed to high temperatures in the presence of oxygen. Without a protective environment, heating CNFs to 800°C would cause them to react with oxygen and burn away.

The vacuum furnace eliminates oxygen from the processing chamber. This creates an inert environment where the material can be heated significantly without degrading or losing mass due to oxidation.

Ensuring Structural Integrity

By preventing chemical reactions with the atmosphere, the vacuum preserves the intrinsic strength of the fiber. This ensures that the purification process enhances the material's properties rather than compromising its structural integrity.

Operational Considerations and Trade-offs

Process Time and Throughput

While effective, vacuum annealing is a batch process that requires significant time. The standard cycle involves not just the three-hour hold time at 800°C, but also the time required to pump down the vacuum and ramp the temperature up and down.

Energy Consumption

Maintaing high temperatures for extended periods is energy-intensive. Operators must balance the need for high purity (which dictates the 800°C/3-hour parameter) against the operational costs of running high-power furnaces.

Optimizing Your Purification Strategy

To achieve the best results with carbon nanofiber purification, align your process parameters with your specific material requirements.

- If your primary focus is maximizing electrical conductivity: Prioritize the complete removal of amorphous carbon to ensure a high degree of graphitization.

- If your primary focus is process yield: Ensure your vacuum levels are strictly maintained to prevent even micro-oxidation, which can reduce the total mass of the final product.

Vacuum annealing is not merely a cleaning step; it is a structural refinement process essential for producing high-grade carbon nanofibers.

Summary Table:

| Feature | Purification Impact | Benefit |

|---|---|---|

| Vacuum Environment | Prevents chemical reactions with O2 | Eliminates oxidation and mass loss |

| 800°C Heat Treatment | Desorbs surface contaminants | Ensures chemical purity of the fiber |

| 3-Hour Hold Time | Removes amorphous carbon defects | Enhances graphitization and strength |

| Thermal Evacuation | Vaporizes residual impurities | Leaves a clean, high-performance surface |

Elevate Your Material Purity with KINTEK

Don't let impurities compromise your carbon nanofiber performance. KINTEK provides industry-leading thermal solutions backed by expert R&D and precision manufacturing. Whether you need specialized Vacuum, Tube, or CVD systems, our lab high-temp furnaces are fully customizable to meet your exact processing parameters.

Ready to optimize your purification workflow? Contact us today to discuss your unique needs and discover how our advanced furnace technology can enhance your lab's efficiency and product quality.

Visual Guide

References

- Teguh Endah Saraswati, Wijang Wisnu Raharjo. Enhanced Performance of Epoxy Resin-Polyimide Hybrid Composites with Aminated Carbon Nanofibers Filler. DOI: 10.26554/sti.2025.10.1.152-164

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- How does a precision vacuum system influence the sulfidation process of MoS2? Master Semiconductor Quality

- How does the multi-chamber continuous vacuum furnace improve industrial processes? Boost Efficiency and Quality

- Can you describe a process example using a vacuum hardening furnace? Achieve Clean, Precise Metal Hardening

- How does a high vacuum drying system facilitate the drying of MgAlhfip? Ensure Purity for Magnesium Electrolytes

- What factors must be controlled during furnace brazing to ensure a reliable joint? Master the 5 Key Variables for Strong Bonds

- What is the role of inert gases in vacuum furnace operations? Protecting Metal Purity After Purification

- How are vacuum furnaces used in the aerospace industry? Enhance Safety and Performance in Aviation

- What is the typical temperature range for vacuum annealing? Tailor Temperatures for Your Material's Needs