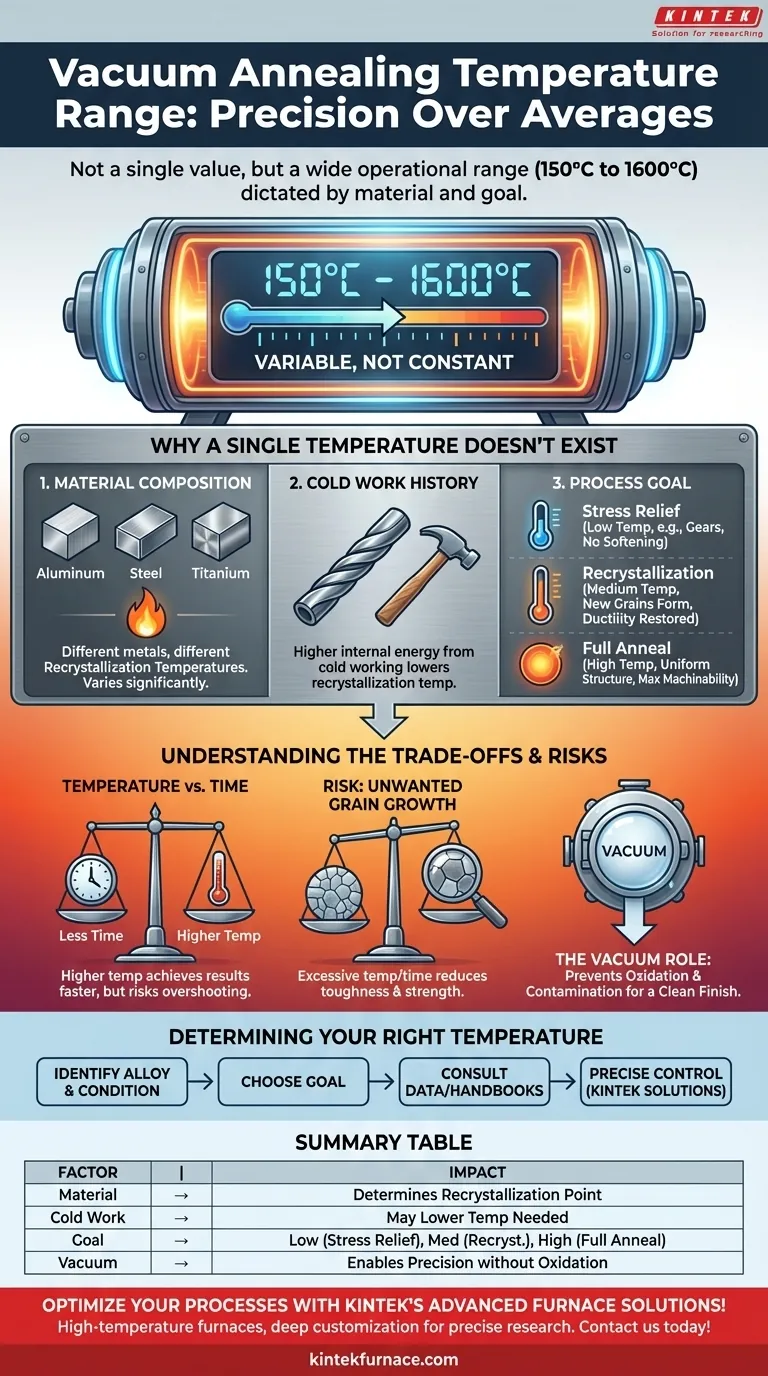

The typical temperature for vacuum annealing is not a single value but a wide operational range, dictated entirely by the specific material and the desired outcome. While vacuum furnaces can operate anywhere from 150°C to 1600°C (300°F to 2900°F), the actual process temperature for a given job is chosen with precision to achieve a specific metallurgical change.

The core principle to understand is that annealing temperature is a variable, not a constant. It must be carefully selected based on the material's composition, its history of cold work, and the specific goal of the treatment, whether it's simply relieving stress or fundamentally altering the grain structure.

Why a Single "Typical" Temperature Doesn't Exist

Simply heating a material is not enough; the temperature must be tailored to the objective. Several critical factors determine the correct temperature, making a one-size-fits-all answer impractical and misleading.

The Role of Material Composition

Different metals and alloys have vastly different properties. A temperature that fully anneals aluminum would have little effect on steel.

Each material has a unique recrystallization temperature—the point at which new, strain-free grains begin to form. This temperature is a primary benchmark for any annealing process.

The Influence of Cold Work

Cold working (such as rolling, drawing, or forging at room temperature) introduces stress and defects into a material's crystal structure.

A heavily cold-worked material has more stored internal energy. This can lower the temperature required to initiate recrystallization and restore its ductility.

The Goal of the Annealing Process

The term "annealing" covers several distinct heat treatments, each with a different temperature profile and purpose.

- Stress Relief: This is done at the lowest temperatures, well below the recrystallization point. Its only goal is to reduce internal stresses from machining or welding without softening the material.

- Recrystallization: This is performed at or just above the recrystallization temperature to eliminate the effects of cold work, making the material softer and more ductile.

- Full Anneal: This requires higher temperatures to create a very uniform and soft grain structure, often for maximum machinability. The cooling rate from this temperature is also critical.

Understanding the Trade-offs

Selecting the right temperature involves balancing desired outcomes against potential risks. The vacuum environment itself plays a key role in ensuring a successful outcome.

Temperature vs. Time

Heat treatment follows a temperature-time relationship. A higher temperature can often achieve the desired result in less time.

However, this acceleration comes with a significant risk. Exceeding the optimal temperature can lead to undesirable effects that cannot be easily reversed.

The Risk of Unwanted Grain Growth

The most common pitfall of using excessive temperature or time is grain growth.

Once recrystallization is complete, grains will continue to grow if the material is held at temperature. Large, coarse grains can significantly reduce a material's toughness and strength.

The Importance of the Vacuum

The primary purpose of using a vacuum is to prevent oxidation and surface contamination. At elevated temperatures, even trace amounts of oxygen can create a destructive oxide layer on the material's surface.

A vacuum environment ensures the finished part is bright, clean, and free from the surface defects that would occur if heated in air.

Determining the Right Temperature for Your Application

To move from theory to practice, you must align the temperature with your specific objective. Always begin by identifying the exact alloy and its condition.

- If your primary focus is stress relieving after machining: You will operate at the lower end of the material's annealing range, well below its critical recrystallization temperature.

- If your primary focus is restoring ductility after heavy cold working: You need to target the material's specific recrystallization temperature, which is found in metallurgical handbooks or material datasheets.

- If your primary focus is achieving maximum softness and machinability: You will likely need a full anneal, which requires higher temperatures and precisely controlled cooling rates as specified for that alloy.

- If you are uncertain about the material's history or properties: Always consult material datasheets or start with established metallurgical guidelines for that specific alloy to avoid costly errors.

Ultimately, precise temperature control is what transforms annealing from a simple heating process into a powerful tool for material engineering.

Summary Table:

| Factor | Impact on Temperature |

|---|---|

| Material Composition | Determines recrystallization temperature; varies by alloy (e.g., aluminum vs. steel). |

| Cold Work Level | Higher cold work may lower recrystallization temperature needed. |

| Process Goal | Stress relief (low temp), recrystallization (medium), full anneal (high temp). |

| Vacuum Environment | Prevents oxidation, allows precise control without contamination. |

Optimize your vacuum annealing processes with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental requirements, enhancing efficiency and material outcomes. Contact us today to discuss how we can support your specific applications!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- What is a vacuum furnace used for? Achieve Purity and Precision in High-Temp Processing

- What is the heat treatment in a vacuum furnace? Achieve Superior Metallurgical Properties

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today

- What is the process of vacuum heat treatment? Achieve Superior Metallurgical Properties

- Why use a vacuum furnace? Achieve Unparalleled Material Purity and Process Control