In the aerospace industry, vacuum furnaces are the essential technology used to heat-treat high-performance materials like titanium and nickel-based superalloys. These processes create the mission-critical components for aircraft engines, landing gear, and airframes, ensuring they possess the extreme strength, heat resistance, and structural integrity required for flight.

The core challenge in aerospace manufacturing is not just shaping metal, but perfecting its internal structure. Vacuum furnaces provide the only environment pure enough to eliminate atmospheric contamination, allowing engineers to precisely control a material's properties to meet non-negotiable safety and performance standards.

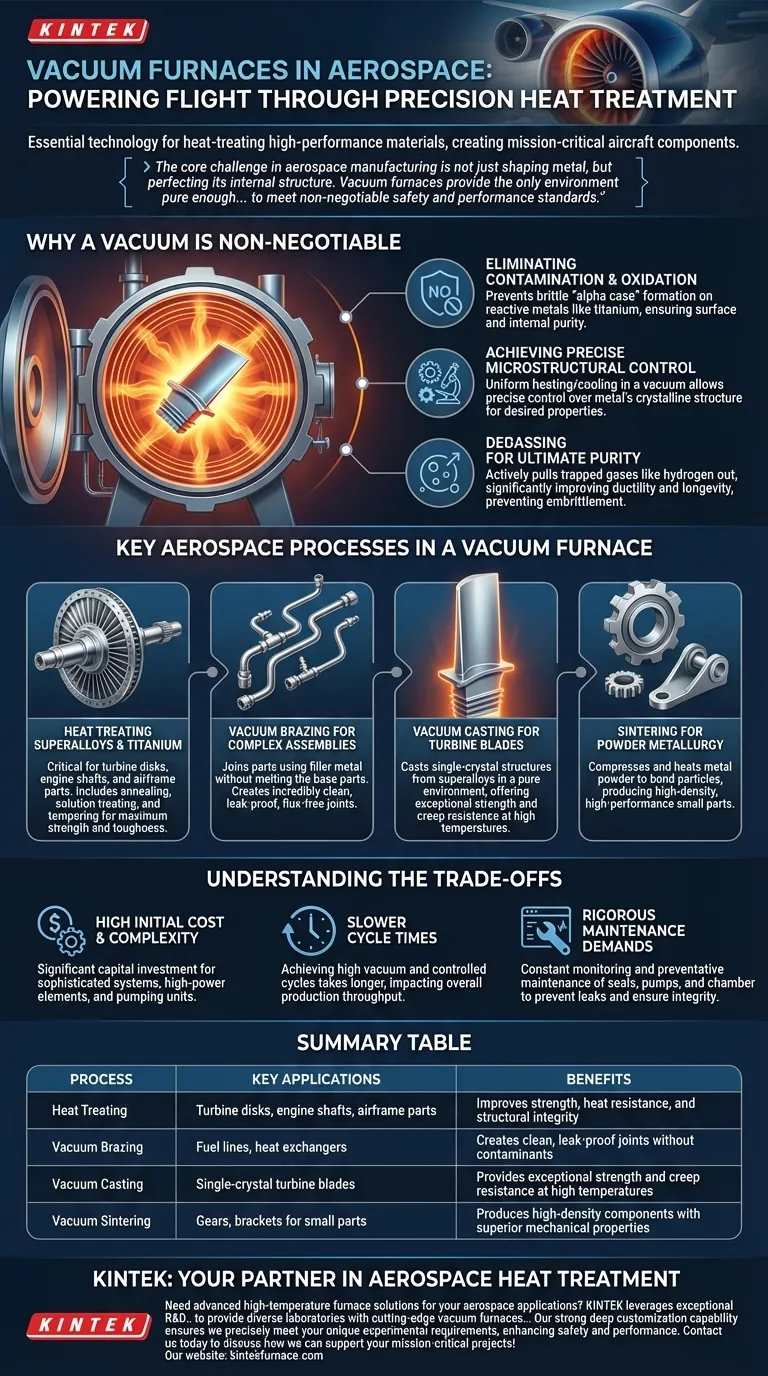

Why a Vacuum is Non-Negotiable

The primary purpose of a vacuum furnace is not the heat, but the absence of air. By removing gases like oxygen and nitrogen, engineers gain absolute control over the material's chemistry during heat treatment.

Eliminating Contamination and Oxidation

When heated in the open air, reactive metals like titanium form a brittle, oxidized outer layer known as "alpha case." This layer compromises the component's strength and fatigue life.

A vacuum environment prevents oxidation and other unwanted chemical reactions, ensuring the material's surface and internal structure remain pure and perform exactly as designed.

Achieving Precise Microstructural Control

Heat treatment processes like annealing and hardening work by altering the crystalline structure (microstructure) of the metal.

The uniform heating and cooling cycles achievable only in a vacuum allow for exceptionally precise control over this structure. This is how a single alloy can be made either soft and malleable for shaping or incredibly hard and strong for its final application.

Degassing for Ultimate Purity

Metals can contain dissolved gases like hydrogen, which can lead to a dangerous form of cracking called hydrogen embrittlement.

The vacuum actively pulls these trapped gases out of the metal during the heating cycle, a process known as degassing. This significantly improves the material's ductility and longevity.

Key Aerospace Processes in a Vacuum Furnace

Different components and materials require specific vacuum furnace processes to achieve their final, perfected state.

Heat Treating Superalloys and Titanium

This is the most common application. Critical components like turbine disks, engine shafts, and structural airframe parts are made from nickel-based superalloys and titanium alloys.

Processes include annealing to relieve stress after forging, solution treating and aging to impart maximum strength, and tempering to add toughness.

Vacuum Brazing for Complex Assemblies

Brazing uses a filler metal to join two parts without melting the parts themselves. In a vacuum, this process is incredibly clean and strong.

Vacuum brazing is used to create complex assemblies like fuel lines or heat exchangers. The resulting joints are leak-proof and free of flux contaminants that could cause corrosion.

Vacuum Casting for Turbine Blades

Modern jet engine turbine blades must withstand temperatures hotter than their own melting point. This is achieved by casting them as a single crystal from a superalloy.

Vacuum casting furnaces provide the tightly controlled, pure environment needed to grow these single-crystal structures, which have exceptional strength and creep resistance at high temperatures.

Sintering for Powder Metallurgy

Some small, complex parts are formed by compressing metal powder into a desired shape and then heating it in a furnace to bond the particles together, a process called sintering.

Vacuum sintering produces parts with higher density and superior mechanical properties compared to atmospheric sintering, making it ideal for high-performance gears and brackets.

Understanding the Trade-offs

While indispensable, vacuum furnace technology comes with inherent complexities and costs that must be managed.

High Initial Cost and Complexity

Vacuum furnaces are sophisticated systems involving vacuum chambers, high-power heating elements, and complex pumping systems. Their acquisition and installation represent a significant capital investment.

Slower Cycle Times

Achieving a high vacuum is a time-consuming process. Pumping down the chamber, running the heat cycle, and controlled cooling takes significantly longer than comparable atmospheric furnace cycles, impacting throughput.

Rigorous Maintenance Demands

The integrity of the vacuum is paramount. Seals, pumps, sensors, and the chamber itself require constant monitoring and preventative maintenance to prevent leaks that could compromise an entire batch of expensive components.

Matching the Process to the Goal

Choosing the right vacuum process is determined entirely by the component's final application and required performance characteristics.

- If your primary focus is engine performance and efficiency: Vacuum casting of single-crystal turbine blades and the heat treatment of nickel superalloys are the most critical processes.

- If your primary focus is airframe integrity and fatigue life: Large-format vacuum furnaces for annealing and stress-relieving massive titanium structural parts are essential.

- If your primary focus is manufacturing small, complex, or high-precision parts: Vacuum brazing and metal sintering offer superior joint quality and net-shape component fabrication, reducing waste.

Ultimately, the use of vacuum furnaces in aerospace is a direct investment in the safety, reliability, and performance that define modern aviation.

Summary Table:

| Process | Key Applications | Benefits |

|---|---|---|

| Heat Treating | Turbine disks, engine shafts, airframe parts | Improves strength, heat resistance, and structural integrity |

| Vacuum Brazing | Fuel lines, heat exchangers | Creates clean, leak-proof joints without contaminants |

| Vacuum Casting | Single-crystal turbine blades | Provides exceptional strength and creep resistance at high temperatures |

| Vacuum Sintering | Gears, brackets for small parts | Produces high-density components with superior mechanical properties |

Need advanced high-temperature furnace solutions for your aerospace applications? KINTEK leverages exceptional R&D and in-house manufacturing to provide diverse laboratories with cutting-edge vacuum furnaces, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements, enhancing safety and performance. Contact us today to discuss how we can support your mission-critical projects!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- What are the proper procedures for handling the furnace door and samples in a vacuum furnace? Ensure Process Integrity & Safety

- What is the vacuum heat treatment process? Achieve Superior Surface Quality and Material Performance

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- What role does a high-temperature vacuum heat treatment furnace play in LP-DED? Optimize Alloy Integrity Today