To ensure the successful synthesis of Cu/Zn-SAN, a tube furnace with flowing nitrogen is strictly required to establish a controlled, inert environment. This setup serves two critical functions: it prevents the oxidation of the carbon substrate and metal atoms, and it facilitates the precise thermal regulation necessary to achieve atomic-level dispersion of copper and zinc, preventing them from aggregating into unwanted nanoparticles.

The integrity of Cu/Zn-SAN relies on completely isolating the material from oxygen while managing thermal kinetics. Flowing nitrogen protects the carbon framework from combustion, while the tube furnace ensures the exact temperature profile needed to anchor metal atoms individually rather than allowing them to fuse into clusters.

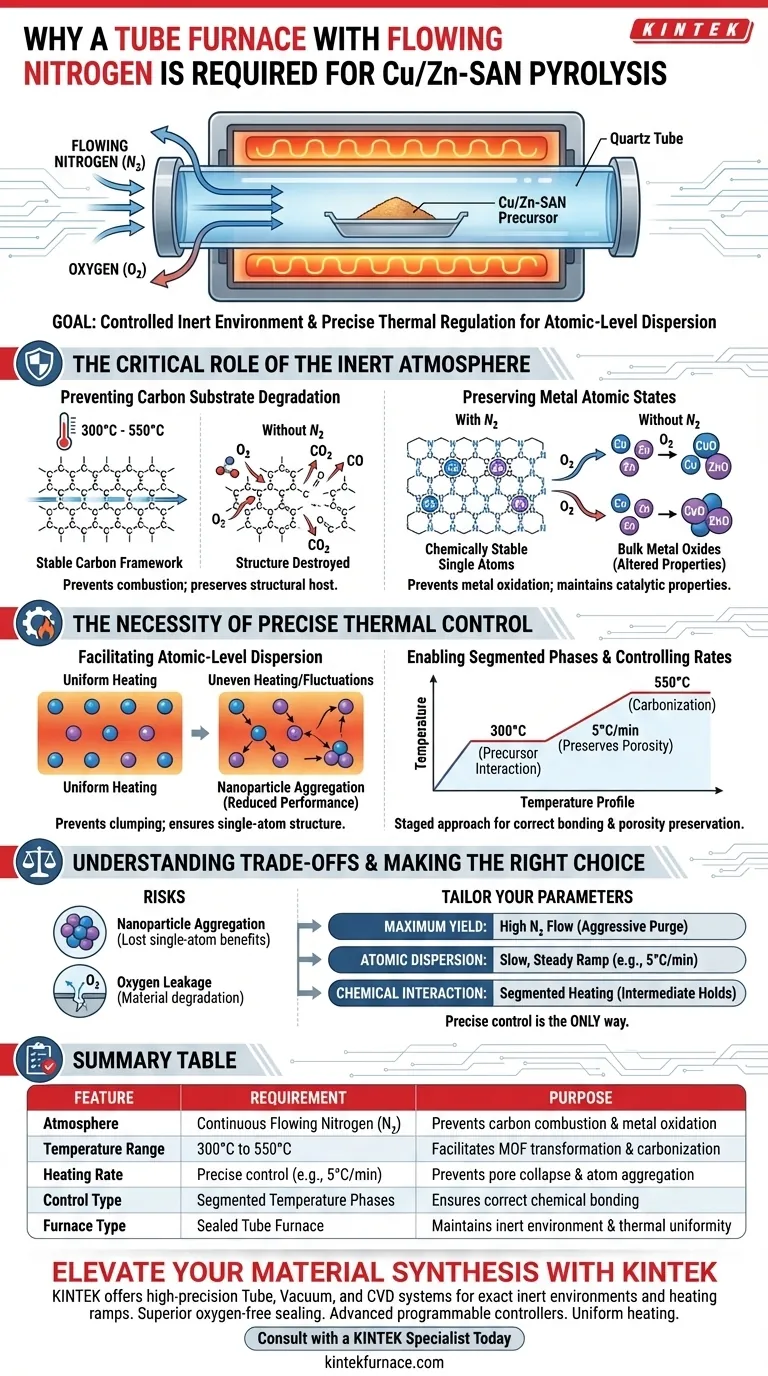

The Critical Role of the Inert Atmosphere

Preventing Carbon Substrate Degradation

The high-temperature pyrolysis process for Cu/Zn-SAN typically operates between 300°C and 550°C.

Without a continuous flow of nitrogen to displace oxygen, the carbon substrate would undergo oxidative combustion at these temperatures. This would destroy the structural framework required to host the metal atoms, resulting in poor yields or complete material loss.

Preserving Metal Atomic States

Nitrogen flow creates a barrier that prevents the metal precursors from oxidizing into unwanted states.

For the material to function correctly, the copper and zinc atoms must be chemically stable. An inert atmosphere ensures that these metals are not converted into bulk metal oxides, which would alter the catalytic properties of the final material.

The Necessity of Precise Thermal Control

Facilitating Atomic-Level Dispersion

The primary goal of using a tube furnace is to achieve atomic-level dispersion of the copper and zinc atoms.

If the temperature fluctuates or the heating mechanism is uneven, metal atoms tend to migrate and clump together. This aggregation forms nanoparticles, which significantly reduces the performance of the material compared to a true single-atom structure.

Enabling Segmented Temperature Phases

A high-precision tube furnace allows for segmented temperature control, which is vital for the chemical transformation of MOF precursors.

For example, the process often requires holding the temperature at 300°C to allow specific interactions (such as between dicyandiamide and the MOF), followed by a ramp to 550°C for carbonization. This staged approach ensures the chemical precursors bond correctly before the final structure locks into place.

Controlling Heating Rates to Preserve Porosity

The specific heating rate—often around 5°C per minute—is a critical variable that only a controlled furnace can maintain.

Rapid heating can cause the structural collapse of the material’s pores. By controlling the ramp rate, the tube furnace preserves the porosity of the nitrogen-doped carbon framework, which is essential for the material's final application.

Understanding the Trade-offs

The Risk of Nanoparticle Aggregation

The most common failure mode in this process is the accidental formation of nanoparticles.

If the inert gas flow is interrupted or the temperature ramp is too aggressive, the single atoms will detach from the nitrogen-doped framework and coalesce. Once these atoms aggregate into larger particles, the unique "single-atom" catalytic benefits are lost, and the material behaves like a standard bulk metal catalyst.

Sensitivity to Oxygen Leakage

Even a minor breach in the tube furnace seal can ruin the synthesis.

While the nitrogen flow is meant to be protective, it relies on the furnace maintaining a positive pressure or a perfect seal. Any ingress of oxygen during the high-temperature phase (300°C–550°C) will immediately degrade the carbon matrix and alter the oxidation state of the active metal centers.

Making the Right Choice for Your Goal

To ensure a successful synthesis, you must tailor your furnace parameters to your specific outcome.

- If your primary focus is Maximum Yield: Ensure the nitrogen flow rate is high enough to aggressively purge all oxygen before heating begins to prevent substrate loss.

- If your primary focus is Atomic Dispersion: Prioritize a slow, steady heating ramp (e.g., 5°C/min) to prevent thermal shock and metal atom aggregation.

- If your primary focus is Chemical Interaction: Utilize segmented heating programs to hold the material at intermediate temperatures (e.g., 300°C) to allow complete precursor interaction.

Precise atmospheric and thermal control is the only way to transform precursors into a functional single-atom catalyst without destroying the carbon framework.

Summary Table:

| Feature | Requirement for Cu/Zn-SAN Pyrolysis | Purpose in Synthesis |

|---|---|---|

| Atmosphere | Continuous Flowing Nitrogen ($N_2$) | Prevents carbon combustion and metal oxidation |

| Temperature Range | 300°C to 550°C | Facilitates MOF transformation and carbonization |

| Heating Rate | Precise control (e.g., 5°C/min) | Prevents pore collapse and metal atom aggregation |

| Control Type | Segmented Temperature Phases | Ensures correct chemical bonding of precursors |

| Furnace Type | Sealed Tube Furnace | Maintains inert environment and thermal uniformity |

Elevate Your Material Synthesis with KINTEK

Precise atmospheric control and thermal stability are non-negotiable for high-performance single-atom catalysts. Backed by expert R&D and manufacturing, KINTEK offers high-precision Tube, Vacuum, and CVD systems designed to maintain the exact inert environments and heating ramps required for your complex pyrolysis projects.

Our customizable lab high-temperature furnaces provide:

- Superior oxygen-free sealing for nitrogen-flow applications.

- Advanced programmable controllers for segmented temperature phases.

- Uniform heating to ensure perfect atomic-level dispersion.

Consult with a KINTEK Specialist Today to find the ideal furnace for your research needs.

Visual Guide

References

- Eslam M. Hamed, Sam Fong Yau Li. Bimetallic Cu/Zn Single‐Atom Nanozyme with Superoxide Dismutase‐Like Activity. DOI: 10.1002/smll.202503879

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What heat treatment processes can be performed using tubular furnaces? Unlock Precision for Materials Science

- What types of atmospheric conditions can tubular furnaces operate under? Master Precise Control for Material Synthesis

- What materials can be processed in tubular furnaces? Versatile Solutions for Metals, Ceramics, and More

- Why is a high-temperature tube furnace required for the secondary activation of KBC? Achieve Precision Pore Structure

- How does the amount of material processed vary between batch and continuous rotary tube furnaces? Scale Your Production Efficiently

- What is the purpose of using an industrial-grade tube furnace for the heat treatment of copper hydroxide precursors?

- What makes tubular furnaces versatile and precise? Unlock Superior Thermal Processing Control

- What conditions does a continuous flow fixed-bed quartz reactor provide? Master CO Oxidation Testing with Cobalt Oxide