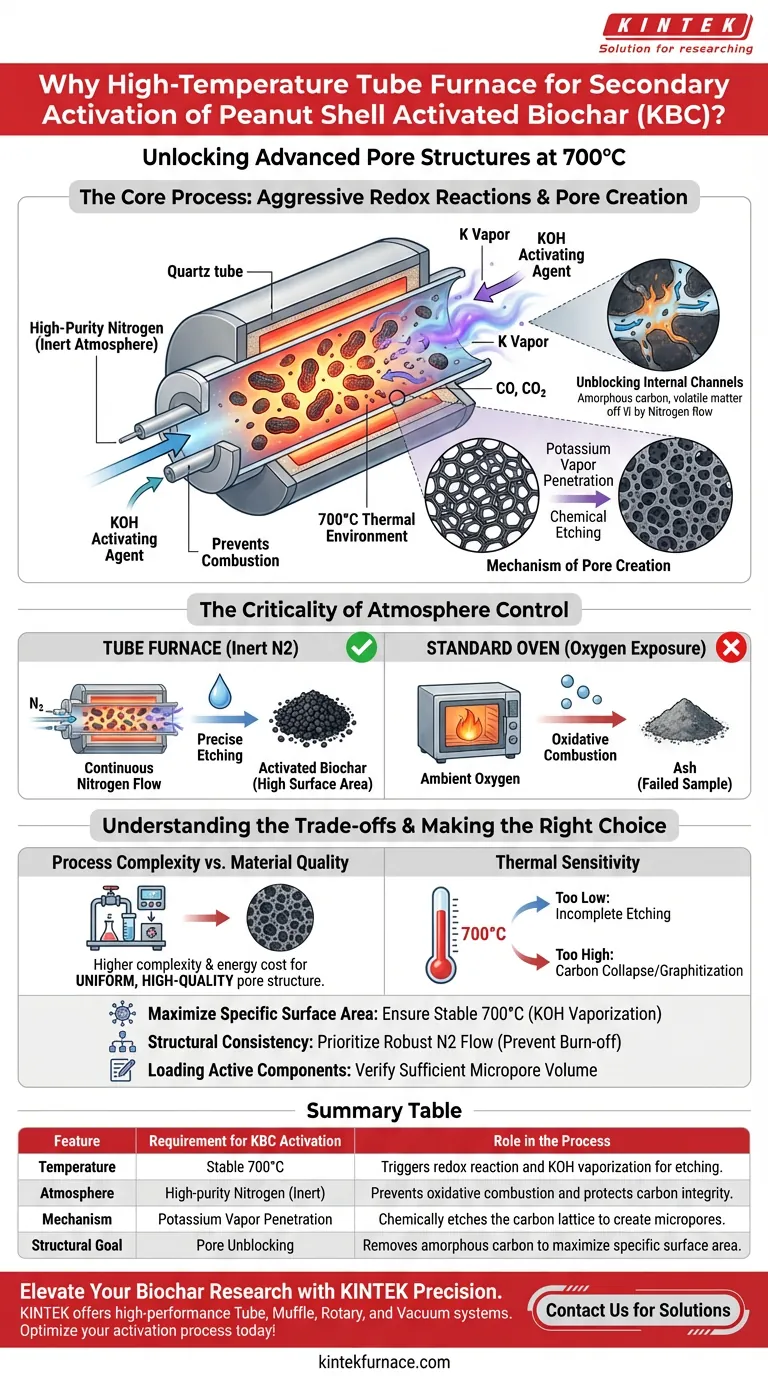

A high-temperature tube furnace is strictly required to facilitate the aggressive redox reactions necessary for secondary activation. It provides a precise thermal environment at 700 °C, enabling activating agents like KOH to physically etch the carbon framework. This process transforms the biochar's internal structure, creating the high specific surface area needed for advanced applications.

The furnace acts as a controlled reactor that turns solid activating agents into penetrating vapors and gases. These agents scour the carbon lattice, carving out micropores to maximize surface area and prepare the material for active component loading.

The Mechanism of Pore Creation

Driving the Redox Reaction

The primary function of the furnace is to reach and maintain the activation temperature of 700 °C.

At this specific thermal threshold, a chemical reaction occurs between the activating agent (KOH) and the biochar framework. This is not merely heating; it is a chemically transformative redox process.

The Role of Potassium Vapor

Inside the furnace, the high heat generates potassium vapor alongside gaseous byproducts like carbon monoxide (CO) and carbon dioxide (CO2).

These vapors penetrate deep into the carbon layers of the peanut shell biochar.

This penetration effectively "etches" the material, removing carbon atoms to create a high volume of microporous structures.

Unblocking Internal Channels

In addition to chemical etching, the thermal treatment helps remove amorphous carbon and volatile matter.

By burning off these disorganized carbon residues, the furnace unblocks internal channels that were previously obstructed.

This reveals and optimizes the latent pore structure of the biochar.

The Criticality of Atmosphere Control

Preventing Unwanted Combustion

A standard oven cannot be used because it typically allows oxygen exposure.

The tube furnace allows for a continuous flow of high-purity nitrogen, creating an inert protective atmosphere.

Without this oxygen exclusion, the biochar would undergo oxidative combustion at 700 °C, turning the sample into ash rather than activated carbon.

Ensuring Precise Etching

The inert environment ensures that the carbon framework is etched solely by the intended activating agent (KOH or CO2), not by ambient oxygen.

This control allows for the precise development of micropores and mesopores without destroying the structural integrity of the biochar.

Understanding the Trade-offs

Process Complexity vs. Material Quality

Using a high-temperature tube furnace introduces complexity regarding gas flow management and energy consumption.

However, this complexity is the cost of achieving a uniform, high-quality pore structure that lower-tech heating methods cannot replicate.

Thermal Sensitivity

The process relies on precise temperature stability; deviations from 700 °C can alter the reaction kinetics.

Too low, and the redox reaction fails to generate sufficient etching vapor; too high, and the carbon framework may collapse or graphitize excessively.

Making the Right Choice for Your Goal

To maximize the efficacy of your activation process, consider the following based on your specific objectives:

- If your primary focus is maximizing specific surface area: Ensure your furnace maintains a stable 700 °C to fully vaporize the KOH, as potassium intercalation is the primary driver of micropore formation.

- If your primary focus is structural consistency: Prioritize a robust nitrogen flow to completely exclude oxygen, preventing uncontrolled burn-off of the carbon skeleton.

- If your primary focus is loading active components: Verify that the etching process has created sufficient microporous volume to physically accommodate the subsequent materials.

The tube furnace is not just a heat source; it is the precision tool that defines the final architecture of your activated biochar.

Summary Table:

| Feature | Requirement for KBC Activation | Role in the Process |

|---|---|---|

| Temperature | Stable 700 °C | Triggers redox reaction and KOH vaporization for etching. |

| Atmosphere | High-purity Nitrogen (Inert) | Prevents oxidative combustion and protects carbon integrity. |

| Mechanism | Potassium Vapor Penetration | Chemically etches the carbon lattice to create micropores. |

| Structural Goal | Pore Unblocking | Removes amorphous carbon to maximize specific surface area. |

Elevate Your Biochar Research with KINTEK Precision

Unlock the full potential of your carbon materials with KINTEK’s advanced thermal solutions. Backed by expert R&D and world-class manufacturing, KINTEK offers high-performance Tube, Muffle, Rotary, and Vacuum systems specifically designed to handle aggressive activation agents and precise temperature protocols. Whether you need a standard setup or a customizable system for unique secondary activation needs, our high-temp furnaces ensure the atmosphere control and thermal stability required for superior pore development.

Ready to optimize your activation process? Contact us today to find your perfect furnace solution!

Visual Guide

References

- Yujie Wang, Shufa Zhu. Hydrothermal synthesis and electrochemical properties of Sn-based peanut shell biochar electrode materials. DOI: 10.1039/d3ra08655k

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What is the operational principle of a 70mm tube furnace? Master Precise Heat and Atmosphere Control

- How does the positioning of a quartz tube in a vertical tube furnace contribute to the stability of the synthesis reaction?

- What is the role of a three-zone tube furnace in the synthesis of single-crystal V2O5 nanosheets? Expert Insights

- What are the technical requirements for an industrial tube furnace for selective chlorination? Reach 1873 K with Precision

- What role does a high-temperature tube furnace play in the calcination of superconducting ceramics? Expert Insights

- What is the temperature range of a High Temperature Tube Furnace? Uncover Key Factors for Optimal Performance

- What are the advantages of multi-zone tube furnaces? Achieve Superior Thermal Control for Advanced Materials Processing

- What does 'single zone' mean in a Split Tube Furnace? Unlock Uniform Heating for Your Lab