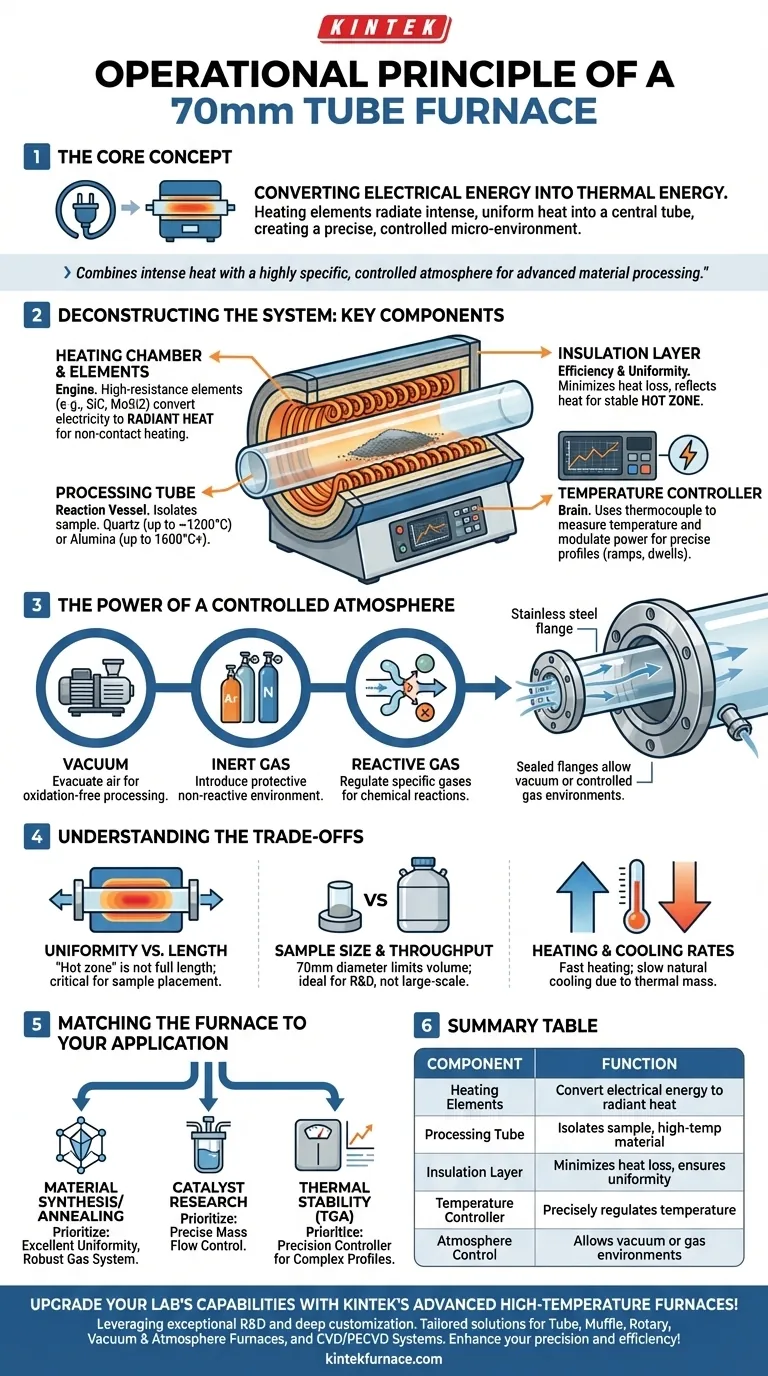

At its core, a 70mm tube furnace operates by converting electrical energy into thermal energy. Heating elements surrounding a central tube radiate heat, which is absorbed by the tube and the sample material placed inside, while a thick layer of insulation minimizes heat loss and ensures temperature uniformity throughout the processing zone.

A tube furnace is more than just a high-temperature oven; it is a precisely controlled micro-environment. Its true operational value lies in its ability to combine intense, uniform heat with a highly specific and controlled atmosphere within the sealed tube, enabling advanced material processing.

Deconstructing the System: Key Components and Their Roles

To understand how the furnace achieves this control, we must examine its core components. Each part serves a distinct and critical function in the overall system.

The Heating Chamber and Elements

The engine of the furnace is the heating chamber. This is where electrical energy is passed through high-resistance heating elements (often made of materials like silicon carbide or molybdenum disilicide).

As electricity flows, these elements glow hot, releasing energy primarily as radiant heat. This design ensures efficient, non-contact heating of the central tube.

The Processing Tube

The defining feature is the 70mm diameter tube, typically made of quartz or high-purity alumina (corundum). This tube acts as the reaction vessel, isolating the sample material from the heating elements and the outside air.

The choice of tube material is critical. Quartz is suitable for many applications up to ~1200°C, while alumina is required for higher temperatures, reaching 1600°C or more.

The Insulation Layer

Surrounding the heating chamber is a multi-layered insulation shield. This component is crucial for two reasons: it prevents heat from escaping into the lab environment, improving energy efficiency, and it reflects heat back toward the tube, promoting temperature uniformity.

A stable and uniform hot zone is essential for consistent and repeatable experimental results.

The Temperature Controller

The brain of the operation is the temperature controller. This microprocessor-based unit uses a thermocouple to constantly measure the temperature inside the chamber.

It then modulates the power sent to the heating elements to precisely follow a user-defined temperature profile, enabling controlled heating rates, specific dwell times, and regulated cooling.

The Power of a Controlled Atmosphere

The ability to manipulate the environment inside the tube is what elevates the furnace from a simple heater to a sophisticated research tool.

Why Atmosphere Matters

Many high-temperature processes, such as semiconductor annealing or nanomaterial synthesis, are highly sensitive to oxygen. A normal air atmosphere would cause unwanted oxidation, ruining the sample.

In other cases, a specific reactive gas is required to participate in a chemical reaction. A controlled atmosphere is therefore non-negotiable for advanced applications.

Achieving Vacuum and Inert Environments

To control the atmosphere, the ends of the tube are sealed with stainless steel flanges. These fittings create an airtight seal and include ports for several functions.

A vacuum pump can be connected to evacuate all air from the tube. Afterward, an inert gas like argon or nitrogen can be introduced to create a protective, non-reactive environment for the sample during heating.

Understanding the Trade-offs

While powerful, the 70mm tube furnace has inherent limitations that must be considered.

Temperature Uniformity vs. Tube Length

The "hot zone," or the area of maximum temperature uniformity, is never the full length of the furnace. It is typically a smaller region in the center. Understanding the length of your specific furnace's hot zone is critical for placing samples correctly.

Sample Size and Throughput

The 70mm inner diameter inherently limits the size and volume of the material that can be processed at one time. This makes the furnace ideal for research, development, and small-batch production, but not for large-scale industrial throughput.

Heating and Cooling Rates

Tube furnaces can generally achieve fast heating rates. However, due to the significant thermal mass and insulation, natural cooling rates can be slow. If rapid cooling (quenching) is required, specialized modifications or procedures are necessary.

Matching the Furnace to Your Application

Choosing and using a tube furnace effectively depends entirely on your end goal.

- If your primary focus is material synthesis or annealing: Prioritize a system with excellent temperature uniformity and a robust gas management system for creating pure inert or vacuum atmospheres.

- If your primary focus is catalyst research: Ensure the furnace has a precise mass flow control system to introduce and regulate specific reactive gases at controlled rates.

- If your primary focus is thermal stability analysis (TGA): The precision of the temperature controller and its ability to execute complex, multi-stage temperature ramps is the most critical feature.

Ultimately, the 70mm tube furnace is a versatile and indispensable tool for anyone needing to subject materials to precise thermal and atmospheric conditions.

Summary Table:

| Component | Function |

|---|---|

| Heating Elements | Convert electrical energy to radiant heat for non-contact heating |

| Processing Tube | Isolates sample, made of quartz or alumina for high-temperature use |

| Insulation Layer | Minimizes heat loss and ensures temperature uniformity |

| Temperature Controller | Precisely regulates temperature via thermocouple and power modulation |

| Atmosphere Control | Allows vacuum or inert/reactive gas environments for oxidation-free processes |

Upgrade your lab's capabilities with KINTEK's advanced high-temperature furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored solutions like Tube Furnaces, Muffle Furnaces, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs for material synthesis, annealing, or catalyst research. Contact us today to discuss how our furnaces can enhance your precision and efficiency!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety