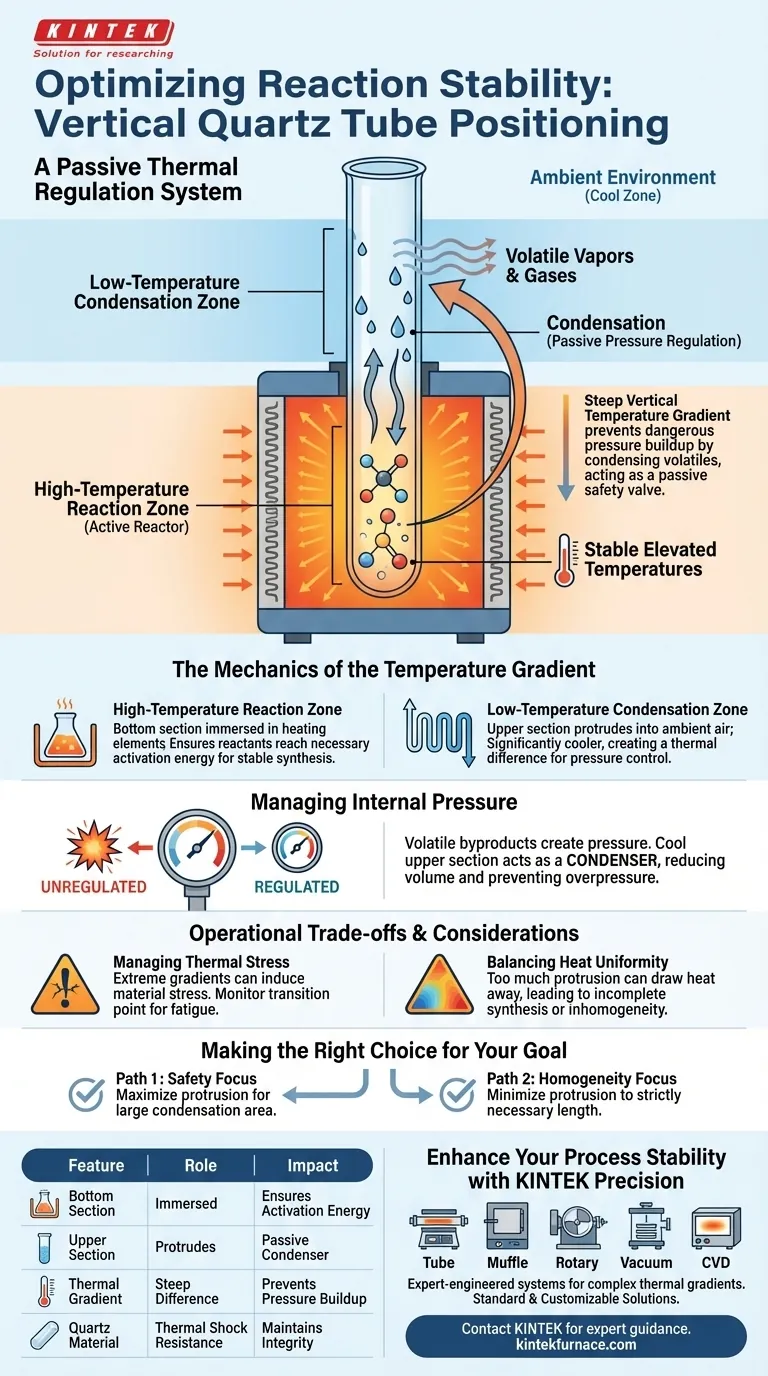

The positioning of the quartz tube acts as a passive thermal regulation system. In a vertical tube furnace, the tube is positioned so that its upper end protrudes significantly outside the heating zone, while the bottom remains submerged in the high-temperature region. This specific geometry creates a steep vertical temperature gradient that is essential for reaction stability. By keeping the top section cool, the setup forces volatile byproducts to condense, which directly prevents dangerous pressure buildup and stabilizes the synthesis environment.

Strategic tube positioning acts as a passive safety valve for the synthesis process. By ensuring the upper end remains cool, the system naturally condenses vapors to control pressure, preventing the risk of explosion or reaction failure caused by overpressure.

The Mechanics of the Temperature Gradient

The High-Temperature Reaction Zone

The bottom section of the quartz tube serves as the active reactor. It is fully immersed in the heating elements of the furnace to ensure reactants reach the necessary activation energy. This positioning guarantees that the synthesis materials are maintained at the stable, elevated temperatures required for the chemical reaction to occur.

The Low-Temperature Condensation Zone

The upper section of the tube is intentionally positioned to protrude into the ambient environment. Because this section is physically removed from the heating zone, it remains significantly cooler than the bottom. This creates a deliberate thermal difference between the reaction site and the exhaust or sealing point.

Managing Internal Pressure

The Volatile Byproduct Challenge

High-temperature synthesis often generates volatile gases or vapors as byproducts. If these gases remain in the hot zone, their kinetic energy prevents them from settling, leading to a rapid increase in internal pressure. Without regulation, this pressure can compromise the structural integrity of the quartz vessel.

Passive Pressure Regulation

The cool, protruding upper section functions effectively as a condenser. As hot vapors rise from the reaction zone, they encounter the cool walls of the protruding tube and revert to liquid or solid states. This phase change drastically reduces the volume of the byproducts, effectively regulating the pressure and preventing system overpressure.

Operational Trade-offs and Considerations

Managing Thermal Stress

While quartz is selected for its thermal shock resistance, extreme gradients can still induce material stress. The transition point between the submerged hot zone and the protruding cool zone acts as a stress riser; this area should be monitored for fatigue or micro-cracking over repeated cycles.

Balancing Heat Uniformity

Positioning the tube too high can create a safety margin that is too aggressive. If the cool zone extends too deep into the furnace, it may draw heat away from the reactants. This can lead to incomplete synthesis or temperature gradients within the sample itself, affecting product homogeneity.

Making the Right Choice for Your Goal

Correct positioning requires balancing the need for uniform heat against the need for pressure mitigation.

- If your primary focus is safety and pressure management: Maximize the protrusion of the upper tube section to ensure a large surface area for the condensation of heavy volatile loads.

- If your primary focus is reaction homogeneity: Minimize the protrusion to the strictly necessary length, ensuring the cooling effect does not encroach upon the reaction zone at the bottom.

Mastering this vertical alignment transforms the quartz tube from a simple container into an active component of your process control system.

Summary Table:

| Feature | Role in Reaction Stability | Impact on Synthesis |

|---|---|---|

| Bottom Section | Immersed in Heating Zone | Ensures activation energy and temperature stability |

| Upper Section | Protrudes into Ambient Air | Acts as a passive condenser for volatile byproducts |

| Thermal Gradient | Steep Vertical Difference | Prevents dangerous pressure buildup via condensation |

| Quartz Material | Thermal Shock Resistance | Maintains structural integrity under extreme gradients |

Enhance Your Process Stability with KINTEK Precision

Proper tube alignment is critical for safety and reaction homogeneity. KINTEK provides expert-engineered Tube, Muffle, Rotary, Vacuum, and CVD systems designed to master complex thermal gradients. Whether you require standard lab high-temp furnaces or fully customizable solutions tailored to your unique research needs, our R&D and manufacturing teams are here to support your success.

Ready to optimize your synthesis environment?

Contact KINTEK today for expert guidance and custom solutions.

Visual Guide

References

- Еvgeny V. Nazarchuk, Dmitri O. Charkin. A novel microporous uranyl silicate prepared by high temperature flux technique. DOI: 10.1515/zkri-2024-0121

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What are the differences between solid tube and split type tube furnaces? Choose the Right Furnace for Your Lab

- Why is a tube furnace with precise temperature control necessary for atmosphere annealing? Master Ceramic Engineering

- What safety features are typically included in vacuum tube furnaces? Essential Protection for High-Temp Labs

- What are the primary functions of a high-performance tube furnace in the two-stage synthesis of Ln-MoP@C catalysts?

- Why is the vertical orientation of a drop tube furnace significant? Unlock Superior Process Control and Efficiency

- What is the function of a high-temperature tube furnace in Cu(111) transformation? Achieve Atomic Precision

- How does a tube furnace contribute to the synthesis of electrocatalysts from hydrochar? Precision Thermal Engineering

- What is the typical workflow when using a multi gradient experimental tube furnace? Master Precision Heating for Your Lab