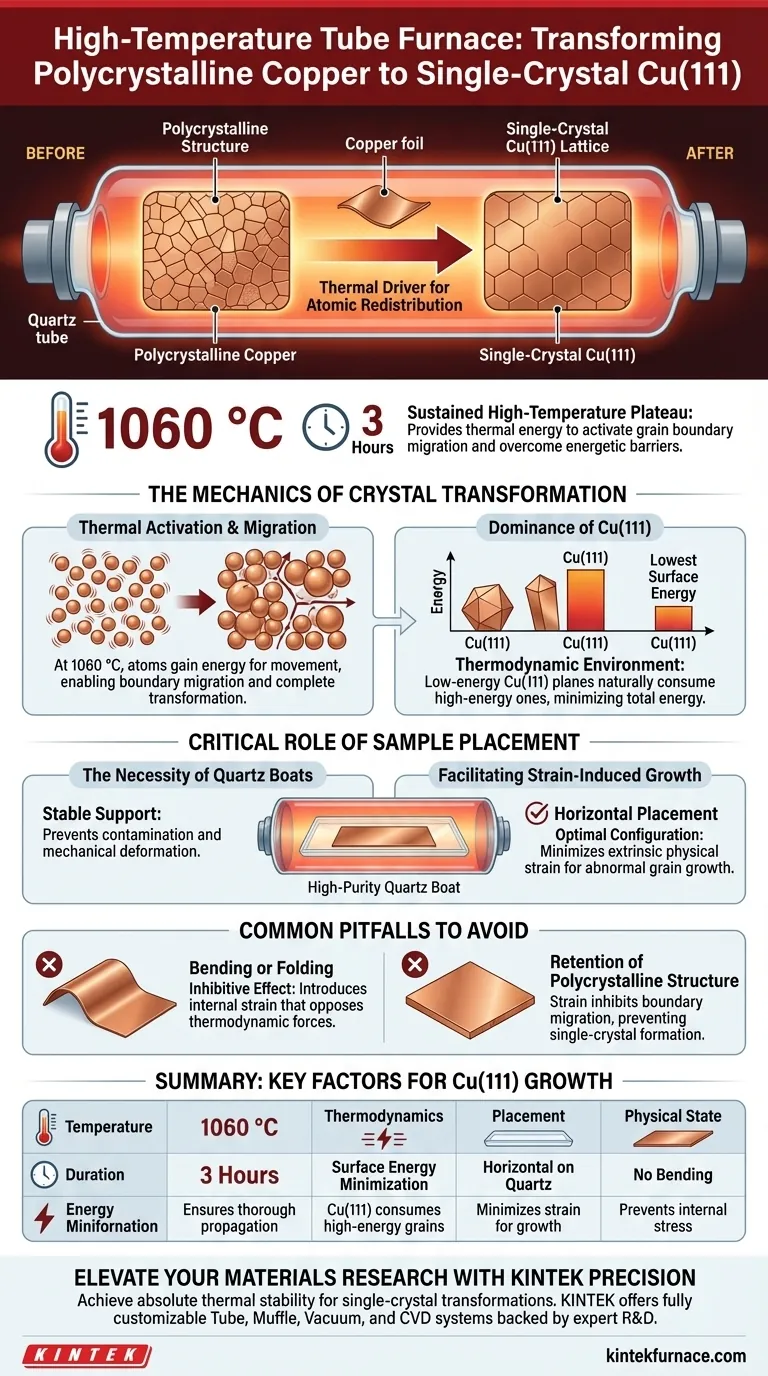

A high-temperature tube furnace functions as the precise thermal driver for atomic redistribution. It maintains a sustained temperature of 1060 °C for three hours, providing the essential thermal energy required to activate grain boundary migration. This controlled environment enables the material to overcome energetic barriers, allowing the polycrystalline structure to evolve into a uniform single-crystal Cu(111) lattice.

The furnace creates a thermodynamic environment where low-energy crystal planes naturally consume high-energy ones. By supplying sufficient activation energy over time, the system minimizes its total energy, effectively unifying the copper foil into a single-crystal structure.

The Mechanics of Crystal Transformation

Thermal Activation and Migration

The primary role of the furnace is to provide the thermal energy necessary for atomic movement. At 1060 °C, the copper atoms gain enough energy to facilitate the migration of grain boundaries.

Without this sustained high-temperature plateau, the atoms would remain locked in their original polycrystalline configuration. The three-hour duration ensures the process is thorough, allowing the transformation to propagate through the entire foil.

The Dominance of Cu(111)

The transformation is driven by the principle of surface energy minimization. Among the various crystal orientations, the Cu(111) surface possesses the lowest surface energy.

In the thermal environment provided by the furnace, grains with the Cu(111) orientation grow by consuming adjacent grains with higher-energy planes. This thermodynamic preference drives the conversion of the entire foil into a single orientation.

The Critical Role of Sample Placement

The Necessity of Quartz Boats

While the furnace provides the heat, the physical support of the copper is equally vital. The copper foil must be placed on a high-purity quartz boat.

This setup ensures the material remains physically stable during the high-temperature annealing process. It prevents contamination and mechanical deformation that could disrupt the crystal lattice.

Facilitating Strain-Induced Growth

Research indicates that placing the foil horizontally on top of the quartz boat is the optimal configuration. This positioning minimizes extrinsic physical strain on the material.

By reducing strain, the setup allows for strain-induced abnormal grain growth, which is the specific mechanism responsible for generating centimeter-scale single-crystal Cu(111).

Common Pitfalls to Avoid

The Inhibitive Effect of Bending

A major trade-off in this process is the material's sensitivity to physical geometry. If the copper foil is bent or folded inside the furnace, the process will likely fail.

These physical deformations introduce internal strain that directly opposes the thermodynamic forces trying to align the crystals.

Retention of Polycrystalline Structure

When strain is present due to improper loading, the single-crystal transformation is inhibited. The energy that should drive boundary migration is instead counteracted by the stress in the material.

Consequently, even after a full three-hour cycle at 1060 °C, the material will retain its original polycrystalline structure rather than transforming into the desired single crystal.

Making the Right Choice for Your Goal

To achieve a high-quality single-crystal Cu(111) transformation, you must control both the thermal profile and the physical handling of the sample.

- If your primary focus is Thermodynamic Activation: Ensure the furnace is calibrated to hold a steady 1060 °C for at least three hours to enable grain boundary migration.

- If your primary focus is Structural Integrity: Place the copper foil horizontally flat on a quartz boat to eliminate bending and strain that inhibit crystal growth.

By combining precise thermal control with strain-free placement, you create the ideal conditions for the thermodynamic dominance of the Cu(111) plane.

Summary Table:

| Parameter/Factor | Requirement/Function | Impact on Cu(111) Growth |

|---|---|---|

| Temperature | 1060 °C | Provides activation energy for grain boundary migration |

| Duration | 3 Hours | Ensures thorough propagation of the single-crystal structure |

| Thermodynamics | Surface Energy Minimization | Allows low-energy Cu(111) planes to consume high-energy grains |

| Placement | Horizontal on Quartz Boat | Minimizes strain to facilitate abnormal grain growth |

| Physical State | No Bending/Folding | Prevents internal stress from inhibiting transformation |

Elevate Your Materials Research with KINTEK Precision

Achieving the perfect single-crystal Cu(111) transformation requires more than just heat; it requires absolute thermal stability and precision. KINTEK provides industry-leading Tube, Muffle, Vacuum, and CVD systems designed to meet the most rigorous laboratory standards.

Backed by expert R&D and world-class manufacturing, our high-temperature furnaces are fully customizable to your unique research needs—ensuring consistent, strain-free results every time.

Ready to optimize your annealing process? Contact our experts today to find the perfect thermal solution for your lab.

Visual Guide

References

- Jia Tu, Mingdi Yan. Chemical Vapor Deposition of Monolayer Graphene on Centimeter-Sized Cu(111) for Nanoelectronics Applications. DOI: 10.1021/acsanm.5c00588

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What are the common applications of a vertical tube furnace? Achieve High-Purity, Uniform Heating for Materials Science

- What maintenance does a horizontal tube furnace require? Ensure Peak Performance and Safety

- What is the function of an industrial tube furnace in studying AlCoCrFeNi coatings? Enhance Material Durability

- What are the key features of three-zone tube furnaces? Unlock Precision for Advanced Materials Processing

- What are the primary industries that use split tube furnaces? Essential for High-Temp Material Processing

- What kind of reaction environment does a laboratory tube furnace provide? Optimize Na4Fe3(PO4)2(P2O7) Synthesis

- How does a tube furnace facilitate the annealing process for Antimony-doped ZnSe and PbSe thin films? Key Performance Tips

- What is the purpose of using high-purity quartz tubes and vacuum sealing for Cu13Se52Bi35 alloy preparation?