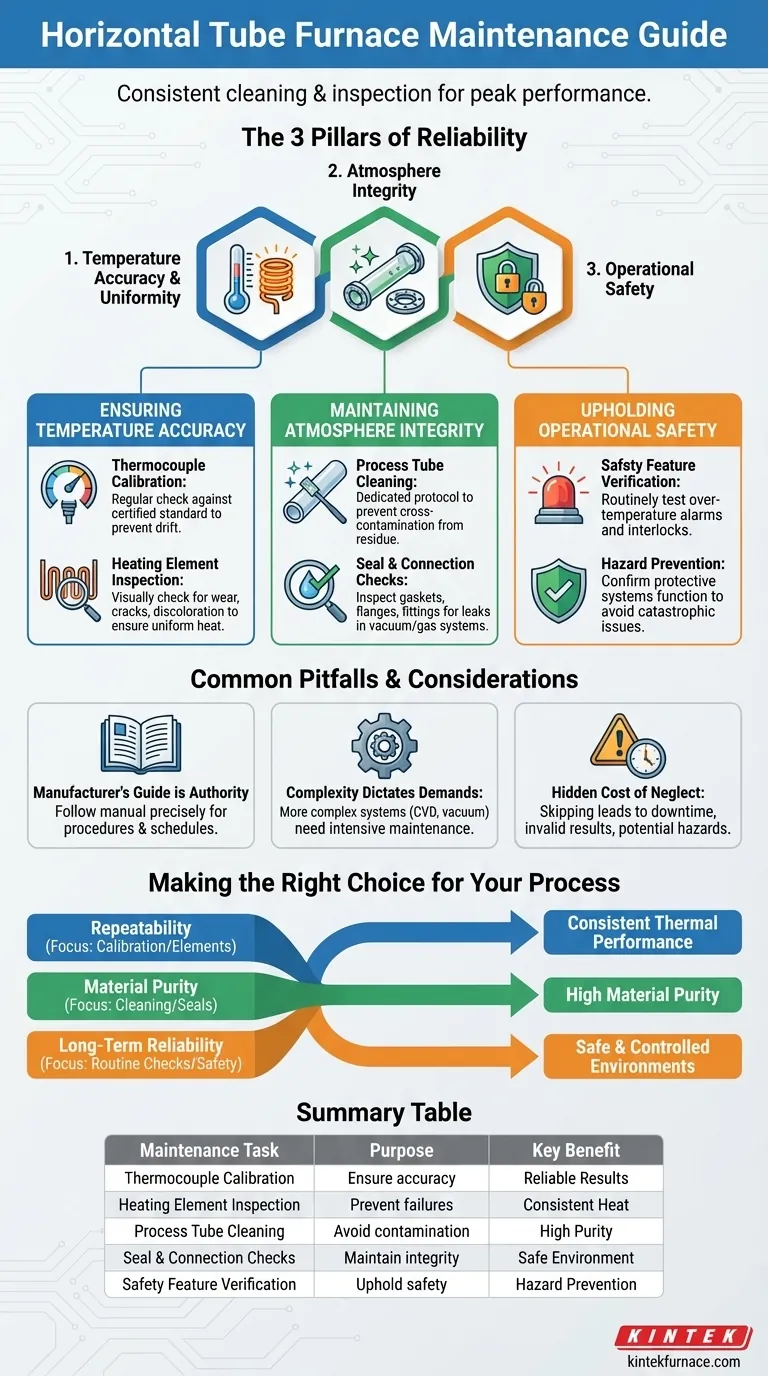

At its core, maintaining a horizontal tube furnace involves a consistent schedule of cleaning and inspection. Key tasks include calibrating temperature sensors, monitoring the condition of heating elements, cleaning the process tube to prevent contamination, and ensuring the integrity of all seals for gas or vacuum applications.

Effective furnace maintenance is not just a checklist of tasks; it's a strategy to preserve the three pillars of performance: temperature accuracy, atmosphere integrity, and operational safety. Proactive upkeep prevents unreliable experimental results, costly downtime, and potential hazards.

The Foundations of Furnace Reliability

A horizontal tube furnace is a precision instrument. Its value comes from its ability to create a highly controlled and uniform thermal environment. Maintenance is the work required to protect that precision.

Ensuring Temperature Accuracy and Uniformity

Your results are only as reliable as your furnace's temperature control.

Thermocouple calibration is essential. The thermocouple is the sensor that reports the temperature to the control system. Over time, these sensors can drift, leading to a discrepancy between the setpoint and the actual temperature inside the tube. Regular calibration against a certified standard is the only way to ensure accuracy.

Heating element inspection prevents failures and ensures uniform heat. Elements degrade with use, which can lead to hot or cold spots along the tube. Visually inspect for signs of wear, cracking, or discoloration, as these are precursors to failure and inconsistent performance.

Maintaining Process Atmosphere Integrity

Many applications, from annealing to chemical vapor deposition (CVD), depend on a pure, controlled atmosphere.

Process tube cleaning is critical to prevent cross-contamination. Residue from a previous run can vaporize and interfere with your current process, ruining sensitive materials. A dedicated cleaning protocol for your specific tube material (e.g., quartz, alumina) is mandatory for repeatable science.

Seal and connection checks guarantee your atmosphere is contained. For vacuum or controlled gas applications, even a minor leak in a flange, gasket, or fitting can compromise the entire experiment. Regularly inspect seals for wear and ensure all connections are tight.

Upholding Operational Safety

A high-temperature furnace presents inherent risks that are managed by built-in safety systems.

Safety feature verification ensures these systems are functional. Routinely test over-temperature protection alarms, which shut down the furnace if it exceeds a safe limit. Confirm that safety interlocks, such as those on the furnace door or casing, are working correctly to protect operators.

Common Pitfalls and Considerations

While the principles are universal, the specific demands of maintenance can vary significantly. Understanding the context of your work is crucial.

Your Manufacturer's Guide Is the Ultimate Authority

This article provides a general framework. However, your furnace manufacturer's manual is the definitive source of truth. It contains specific procedures, schedules, and recommended spare parts unique to your model. Always follow it precisely.

Complexity Dictates Maintenance Demands

A simple air atmosphere furnace used for basic heat treating has far fewer maintenance points than a multi-gas CVD furnace. Systems with complex gas plumbing, vacuum pumps, and exhaust scrubbers require a much more intensive and technically demanding maintenance regimen.

The Hidden Cost of Neglect

Skipping maintenance may seem to save time in the short term, but it leads to significant costs later. A failed heating element can halt operations for days. A contaminated process can invalidate weeks of research. An ignored safety issue can have catastrophic consequences.

Making the Right Choice for Your Process

Tailor your maintenance schedule to the most critical aspect of your work.

- If your primary focus is process repeatability: Prioritize a strict schedule for thermocouple calibration and heating element inspection to guarantee consistent thermal performance run after run.

- If your primary focus is material purity: Your most important task is fanatical adherence to process tube cleaning and verifying the integrity of all gas and vacuum seals.

- If your primary focus is long-term reliability: Implement a routine checklist to inspect all components for wear and to test all safety interlocks and alarms.

Proactive maintenance is an investment in the accuracy of your results and the longevity of your equipment.

Summary Table:

| Maintenance Task | Purpose | Key Benefit |

|---|---|---|

| Thermocouple Calibration | Ensure temperature accuracy | Reliable experimental results |

| Heating Element Inspection | Prevent failures and ensure uniform heat | Consistent thermal performance |

| Process Tube Cleaning | Avoid cross-contamination | High material purity |

| Seal and Connection Checks | Maintain atmosphere integrity | Safe and controlled environments |

| Safety Feature Verification | Uphold operational safety | Hazard prevention and compliance |

Optimize your laboratory's performance with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs, enhancing efficiency and reliability. Contact us today to discuss how we can support your specific requirements and deliver tailored solutions for superior results!

Visual Guide

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- What function does a tube furnace serve in the PVT growth of J-aggregate molecular crystals? Mastery of Thermal Control

- How is a Vertical Tube Furnace used for fuel dust ignition studies? Model Industrial Combustion with Precision

- How does a tube heating furnace facilitate the carbon coating process? Boost Layered Oxide Conductivity

- How do roller kilns and tube furnaces differ in their use of Alumina ceramic tubes? Compare Transport vs. Containment