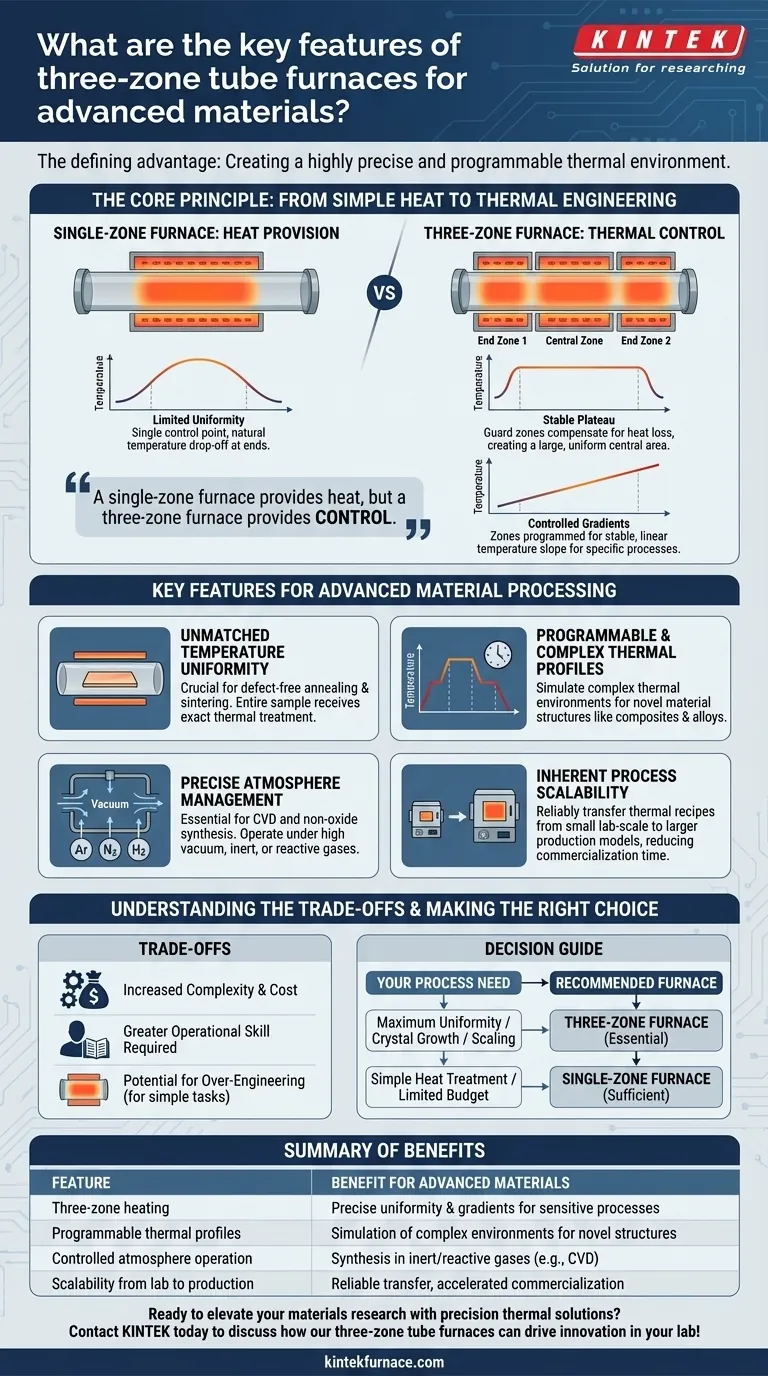

The defining advantage of a three-zone tube furnace is its ability to create a highly precise and programmable thermal environment. Unlike single-zone models, these furnaces use two additional "guard" heating zones at the ends to compensate for natural heat loss. This design allows for an exceptionally uniform temperature across a larger central area or the creation of deliberate, stable temperature gradients, both of which are critical for processing sensitive advanced materials.

A single-zone furnace provides heat, but a three-zone furnace provides control. It empowers you to precisely engineer the thermal landscape your material experiences, which is the fundamental requirement for achieving repeatable, high-quality results in modern materials science.

The Core Principle: From Simple Heat to Thermal Engineering

The jump from a single-zone to a three-zone furnace represents a shift in philosophy. The goal is no longer just to make something hot, but to control how it gets hot, where it is hottest, and for how long.

The Limitation of Single-Zone Furnaces

A standard single-zone furnace has one heating element and one control point. While effective for simple applications, the temperature naturally drops off near the ends of the tube. This results in a very small area of true temperature uniformity.

How Three Zones Create a Stable Plateau

A three-zone furnace tackles this problem directly. The two end zones are programmed to a slightly higher temperature, acting as thermal barriers that counteract heat loss. This forces the central zone to be much larger and more uniform, creating a stable temperature "plateau" ideal for sensitive processes.

Engineering Deliberate Temperature Gradients

Alternatively, the zones can be programmed with different setpoints to create a stable, linear temperature slope across the tube. This controlled gradient is essential for specific processes like chemical vapor transport and certain types of crystal growth, where materials must move through different thermal stages.

Key Features for Advanced Material Processing

The unique design of a three-zone furnace delivers several capabilities that are non-negotiable for fabricating next-generation materials.

Unmatched Temperature Uniformity

For processes like annealing semiconductor wafers or sintering high-purity ceramics, even minor temperature variations can introduce defects and ruin the final product. A three-zone furnace's ability to create a long, stable hot zone ensures that the entire sample receives the exact same thermal treatment.

Programmable and Complex Thermal Profiles

These furnaces allow researchers to program a sequence of temperature changes over time across different zones. This simulates complex thermal environments required for fabricating advanced composites, lightweight alloys, or battery electrodes, enabling the creation of novel material structures.

Precise Atmosphere Management

Advanced material synthesis, such as Chemical Vapor Deposition (CVD) for 2D materials, often cannot happen in the presence of oxygen. Tube furnaces are designed to operate under controlled atmospheres, whether it's a high vacuum, an inert gas like argon, or a specific reactive gas mixture.

Inherent Process Scalability

A thermal recipe perfected in a small, lab-scale three-zone furnace can be reliably transferred to a larger pilot- or production-scale model. This continuity is a massive advantage, drastically reducing the time and cost required to move a new material from discovery to commercialization.

Understanding the Trade-offs

While powerful, a three-zone furnace is not always the default choice. Its advantages come with clear trade-offs that must be considered.

Increased Complexity and Cost

The addition of two extra heating zones, controllers, and thermocouples makes these systems inherently more complex and expensive than their single-zone counterparts. The initial investment is significantly higher.

Greater Operational Skill Required

Properly programming and calibrating a three-zone furnace to achieve a desired profile—whether a flat plateau or a specific gradient—requires more technical expertise. It is not a "plug-and-play" device and demands a deeper understanding of heat transfer principles.

Potential for Over-Engineering

For simple heat treatments, powder calcination, or processes involving materials that are not highly sensitive to thermal variations, a three-zone furnace may be unnecessary. A simpler, more cost-effective single-zone furnace is often sufficient for these tasks.

Making the Right Choice for Your Application

Your decision should be driven entirely by the precision your process demands.

- If your primary focus is maximum temperature uniformity: A three-zone furnace is essential for creating the large, stable hot zone required for annealing, sintering, or uniform coating processes.

- If your primary focus is crystal growth or vapor deposition: The ability to create and precisely control a stable temperature gradient makes a three-zone furnace the necessary tool for the job.

- If your primary focus is scaling a process from R&D to production: The process integrity offered by three-zone furnaces at different sizes will significantly accelerate your path to commercialization.

- If your primary focus is simple heat treatment on a limited budget: A single-zone furnace likely provides a more cost-effective solution, provided your material is not highly sensitive to thermal gradients.

Ultimately, choosing the right furnace is about matching the tool's capability to the specific needs of your material.

Summary Table:

| Feature | Benefit for Advanced Materials |

|---|---|

| Three-zone heating | Enables precise temperature uniformity and gradients for sensitive processes |

| Programmable thermal profiles | Allows simulation of complex thermal environments for novel material structures |

| Controlled atmosphere operation | Supports synthesis in inert or reactive gases, essential for CVD and other methods |

| Scalability from lab to production | Facilitates reliable process transfer, reducing time to commercialization |

Ready to elevate your materials research with precision thermal solutions?

At KINTEK, we specialize in advanced high-temperature furnaces designed for demanding applications. Leveraging our exceptional R&D and in-house manufacturing, we offer a diverse product line including Tube Furnaces, Muffle Furnaces, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we can precisely meet your unique experimental requirements, whether you're working with semiconductors, ceramics, or other advanced materials.

Contact us today to discuss how our three-zone tube furnaces and other solutions can drive innovation in your lab!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety