At its core, a vertical tube furnace is a specialized tool for high-temperature processes where the orientation of the sample is critical to the outcome. Its most common applications are in materials science and chemistry, including the heat treatment of powders, semiconductor wafer processing, material synthesis, and specialized testing methods like gas quenching.

While it performs many of the same functions as a standard horizontal furnace, the vertical tube furnace offers unique advantages rooted in its design. Its vertical orientation leverages gravity to ensure sample uniformity and minimizes particle contamination, making it the superior choice for specific high-purity and powder-based applications.

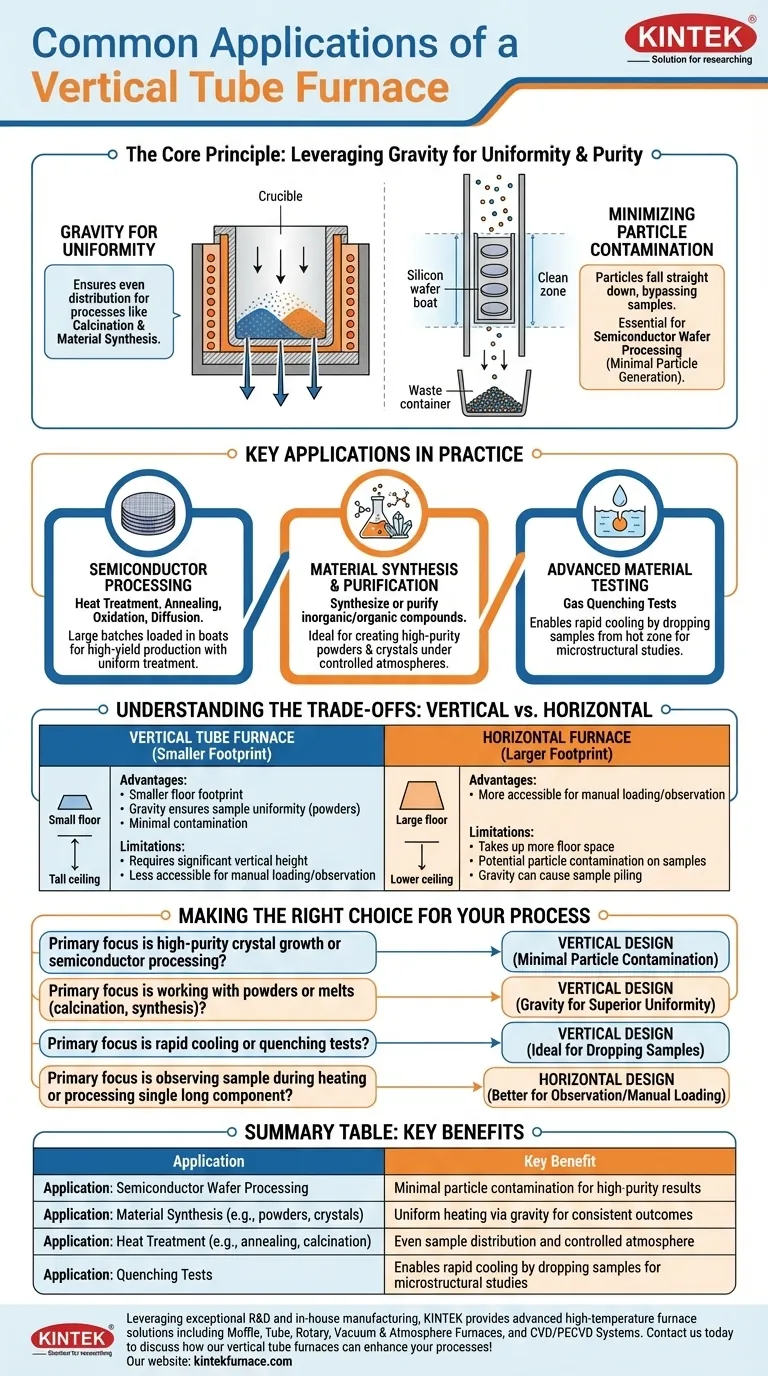

The Principle of Vertical Orientation: Gravity and Purity

The decision to use a vertical furnace over a horizontal one is almost always driven by the physical nature of the sample and the need for process purity. The vertical design fundamentally changes how the sample interacts with the heat and the furnace environment.

Leveraging Gravity for Uniformity

In a vertical furnace, gravity ensures that powders, melts, or liquids settle evenly at the bottom of a crucible. This prevents the sample from piling up against one side, a common issue in horizontal setups.

This even distribution is critical for achieving uniform heat exposure throughout the material. It is essential for processes like calcination, where a powder must be heated consistently to drive off volatile substances, and material synthesis, where reactants must be heated uniformly to form a new compound.

Minimizing Particle Contamination

For high-purity applications, such as semiconductor manufacturing, minimizing contamination is paramount. In a horizontal furnace, particles can flake from the top of the process tube and fall onto the sample below.

A vertical orientation solves this problem. Any particles that dislodge from the tube walls will fall straight down, bypassing the sample holder (or "boat") and collecting harmlessly at the bottom. This results in minimal particle generation on the sample itself, a key requirement for processing sensitive electronic materials like wafers.

Enabling Specific Test Methods

The vertical setup is uniquely suited for experiments that require a sample to be dropped. This is most common in quenching tests, where a material is heated to a precise temperature and then rapidly cooled to freeze its microstructure.

In a vertical furnace, the sample can be suspended in the hot zone and then released, dropping into a lower, cooler zone or a quenching medium like water or gas. This provides a repeatable and rapid cooling rate that is difficult to achieve in a horizontal orientation.

Key Applications in Practice

The design advantages of a vertical furnace directly translate into its primary industrial and laboratory applications.

Heat Treatment and Annealing

Vertical furnaces are widely used for heat treatment processes like thermal annealing, oxidation, and diffusion. This is especially true in the semiconductor industry, where large batches of silicon wafers are loaded into "boats" and processed simultaneously.

The excellent temperature uniformity and low particle contamination ensure that every wafer in the batch receives the exact same treatment, leading to high-yield production of integrated circuits.

Material Synthesis and Purification

Chemists and material scientists use vertical furnaces to synthesize or purify inorganic and organic compounds. The ability to control the atmosphere (e.g., vacuum, inert gas) combined with uniform heating makes it ideal for creating high-purity powders and crystals.

Advanced Material Testing

In research settings, vertical furnaces are essential for conducting tests under highly controlled conditions. This includes gas quenching tests under vacuum or a specific atmosphere to study how materials respond to rapid cooling without oxidation.

Understanding the Trade-offs

A vertical tube furnace is a specialized instrument, not a universal solution. Understanding its limitations compared to a horizontal furnace is key.

Footprint vs. Accessibility

A vertical furnace has a smaller floor footprint, making it an excellent choice for crowded labs. However, it requires significant vertical ceiling height, which can be a limitation.

Horizontal furnaces, while taking up more floor space, are often more accessible for manual loading and observation.

Gravity's Role: Help or Hindrance?

Gravity is the vertical furnace's greatest asset for powders and melts. However, it is a hindrance for applications where a sample needs to be held in a specific, non-vertical position or rotated during processing.

Observing a sample during heating is also much easier in a horizontal furnace, which often features a side-viewing port.

Sample Loading and Throughput

Automated wafer and boat transfer systems are common in vertical furnaces, improving productivity for batch processing.

For processes involving long, continuous materials or where manual sample placement is preferred, a horizontal furnace is often easier to load and manage.

Making the Right Choice for Your Process

Choosing the correct furnace requires matching the equipment's core strengths to your experimental or production goals.

- If your primary focus is high-purity crystal growth or semiconductor processing: The vertical design's minimal particle contamination is a decisive advantage.

- If your primary focus is working with powders or melts (like calcination or synthesis): A vertical furnace's use of gravity ensures superior sample uniformity and consistent results.

- If your primary focus is rapid cooling or quenching tests: The ability to drop a sample from the hot zone makes a vertical furnace the ideal choice.

- If your primary focus is observing the sample during heating or processing a single, long component: A horizontal furnace will better serve your needs.

Ultimately, understanding the fundamental role of gravity and purity in your process is the key to selecting the right furnace for your work.

Summary Table:

| Application | Key Benefit |

|---|---|

| Semiconductor Wafer Processing | Minimal particle contamination for high-purity results |

| Material Synthesis (e.g., powders, crystals) | Uniform heating via gravity for consistent outcomes |

| Heat Treatment (e.g., annealing, calcination) | Even sample distribution and controlled atmosphere |

| Quenching Tests | Enables rapid cooling by dropping samples for microstructural studies |

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. If you're working in materials science, chemistry, or semiconductor fields and need reliable, high-purity heating equipment, contact us today to discuss how our vertical tube furnaces can enhance your processes and deliver precise, contamination-free results!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab