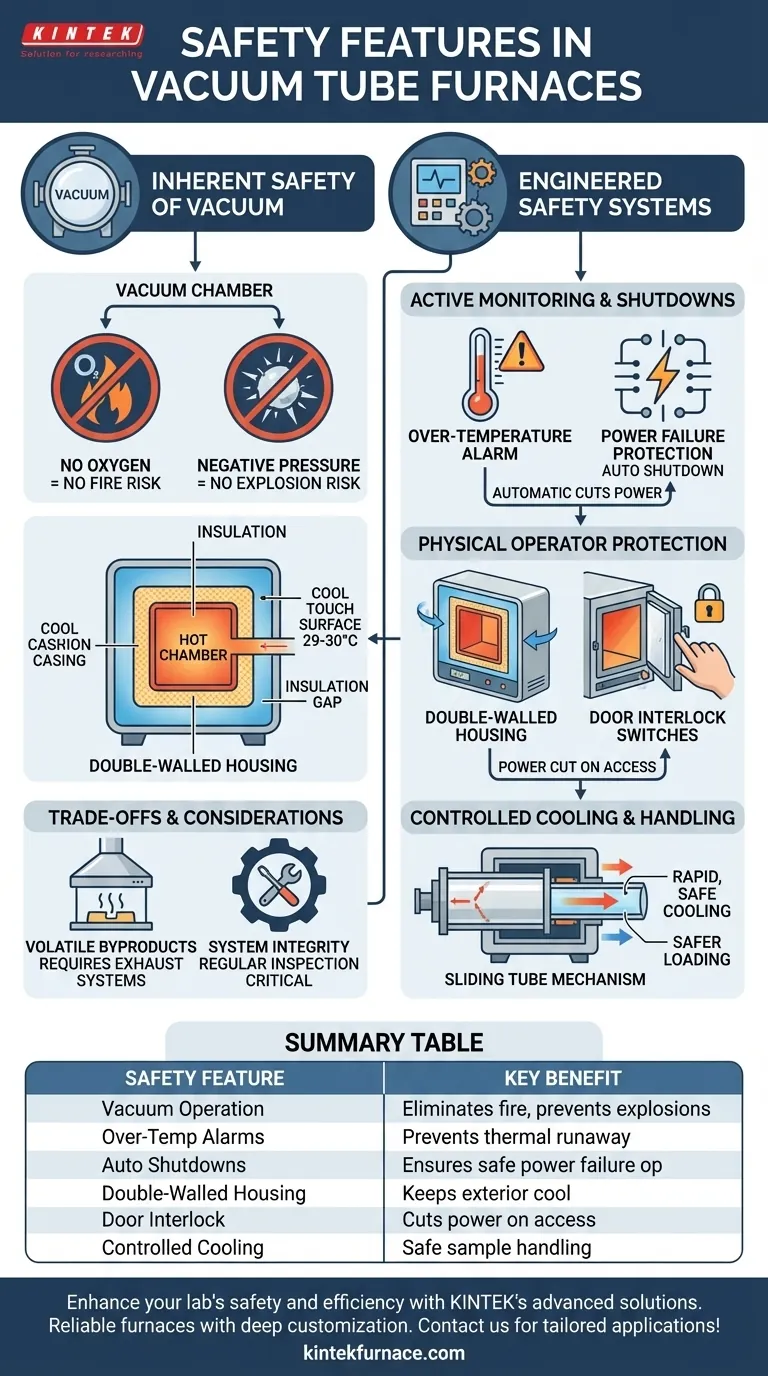

In practice, a modern vacuum tube furnace integrates multiple layers of safety features designed to protect both the operator and the equipment. The primary safety mechanisms include active electronic monitoring systems like over-temperature alarms and automatic power-failure shutdowns, combined with physical design elements such as double-walled housing that keeps the exterior cool to the touch.

The safety of a vacuum tube furnace is rooted in two distinct principles: the inherent safety of operating in a vacuum, which removes the fuel for fires and the risk of pressure explosions, and the engineered control systems that actively prevent equipment failure and protect the operator from high temperatures.

The Inherent Safety of Operating in a Vacuum

Before examining specific hardware features, it's crucial to understand why a vacuum environment is fundamentally safer for high-temperature processes than an ambient air environment.

Eliminating the Risk of Fire

A vacuum, by definition, is a space with extremely low oxygen content. Since oxygen is a necessary component for combustion, operating within a vacuum virtually eliminates the risk of fire from the oxidation of materials or components inside the furnace.

This makes vacuum furnaces significantly safer than furnaces that heat materials in the presence of air or an oxygen-rich atmosphere.

Preventing Pressure-Related Explosions

Vacuum furnaces operate at negative pressure. Unlike pressure vessels or boilers that can build up internal pressure to dangerous levels, a vacuum furnace cannot explode from over-pressurization.

Any leak in the system results in atmospheric pressure entering the chamber, causing the system to equalize rather than fail catastrophically.

Engineered Safety Systems

While the vacuum provides a safe operating environment, engineered systems provide active protection against equipment failure and direct harm to personnel.

Active Monitoring and Automatic Shutdowns

The most critical active safety features are over-temperature alarms and power failure protection.

If the internal temperature exceeds a pre-set safety limit, the system automatically cuts power to the heating elements to prevent a thermal runaway event. Similarly, in the event of a power outage, the furnace is designed to shut down safely.

Physical Operator Protection

Protecting the user from extreme heat is a primary design goal. This is achieved through several physical features.

Double-walled housing is a standard design where a layer of air or insulation separates the inner hot chamber from the outer casing. This design keeps the external surface temperature remarkably low—often around 29-30°C (84-86°F)—even when the furnace is operating at 800°C (1472°F) or higher.

Many furnaces also incorporate positive break safety switches or interlocks. These switches automatically cut power to the heating elements the moment the furnace door or tube access is opened, preventing operator exposure to live electrical components and extreme heat.

Controlled Cooling and Material Handling

Modern designs often feature a compact sliding tube mechanism. This allows the tube to be moved out of the heating zone for more rapid and controlled cooling, which also makes loading and unloading samples safer and more efficient.

Understanding the Trade-offs and Considerations

While inherently safe, the overall safety of the operation depends on its correct use and an awareness of the materials being processed.

Handling of Volatile Byproducts

The vacuum itself is safe, but heating certain materials can release volatile compounds or hazardous fumes. The furnace is a closed system, but these byproducts must be handled safely by the vacuum pump and exhaust system.

In applications involving such materials, the furnace setup must be integrated with appropriate fume hoods or local exhaust systems to ensure operator safety and regulatory compliance.

Dependence on System Integrity

The safety benefits of the vacuum are entirely dependent on the integrity of the furnace chamber, seals, and the vacuum pump. A leak will compromise the inert environment, potentially allowing oxidation or unwanted reactions to occur.

Regular maintenance and inspection of all vacuum components are therefore critical for ensuring continued safe operation.

Evaluating Safety for Your Application

When selecting a vacuum tube furnace, consider how its safety features align with your specific laboratory or production needs.

- If your primary focus is operator safety: Look for models with certified low external surface temperatures, robust door interlock switches, and ergonomic designs for loading and unloading.

- If your primary focus is process stability and reliability: Prioritize furnaces with precise, programmable digital controllers and redundant over-temperature protection systems.

- If you are working with reactive or volatile materials: Ensure the furnace and its vacuum system are compatible with the necessary gas handling and exhaust safety equipment.

Ultimately, understanding how these inherent and engineered safety systems work together empowers you to operate high-temperature equipment with confidence and control.

Summary Table:

| Safety Feature | Key Benefit |

|---|---|

| Vacuum Operation | Eliminates fire risk and prevents explosions |

| Over-Temperature Alarms | Prevents thermal runaway and equipment damage |

| Automatic Shutdowns | Ensures safe operation during power failures |

| Double-Walled Housing | Keeps exterior cool to protect operators |

| Door Interlock Switches | Cuts power when opened for enhanced safety |

| Controlled Cooling Systems | Allows safe sample handling and rapid cooling |

Enhance your lab's safety and efficiency with KINTEK's advanced high-temperature furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable vacuum tube furnaces, muffle furnaces, tube furnaces, rotary furnaces, and CVD/PECVD systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements, delivering tailored safety and performance. Contact us today to discuss how our solutions can benefit your specific applications!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- How is a Vertical Tube Furnace used for fuel dust ignition studies? Model Industrial Combustion with Precision