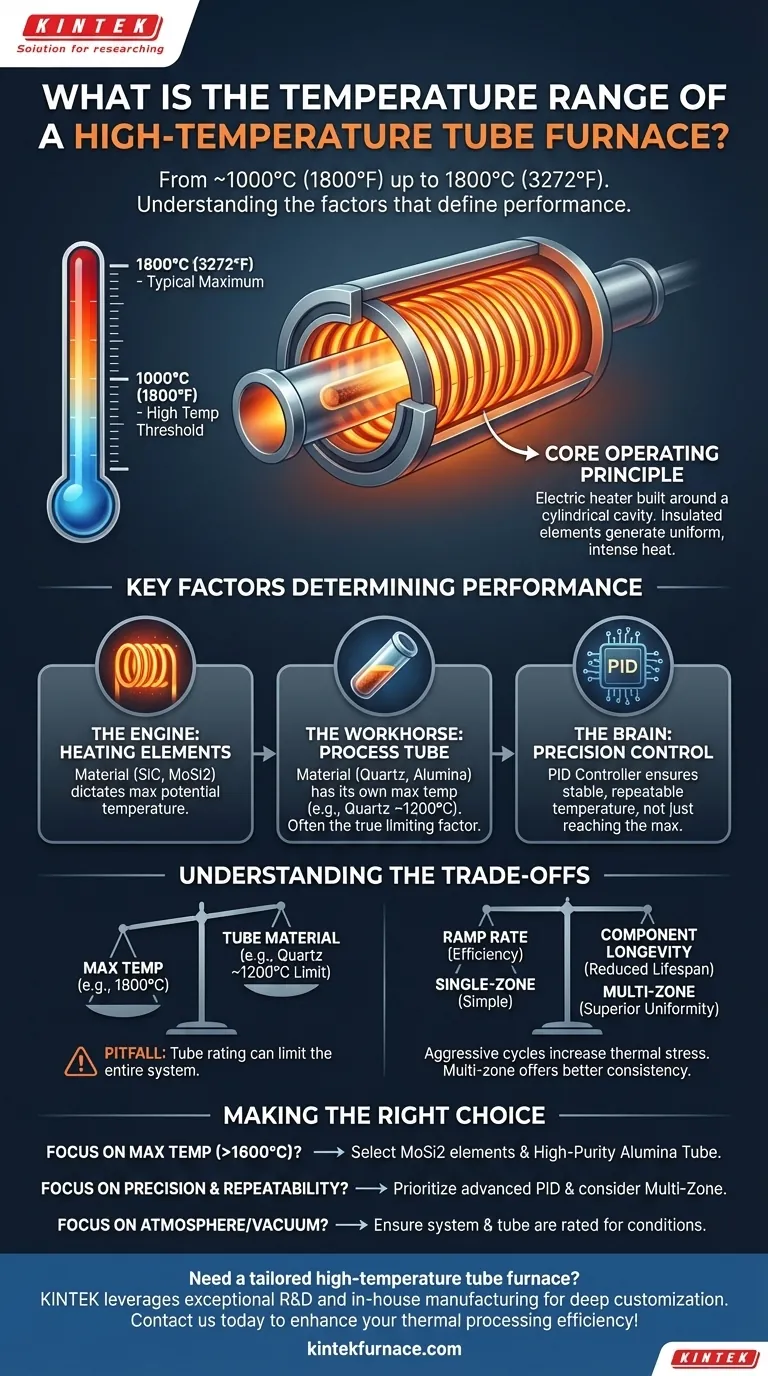

In short, a high-temperature tube furnace typically operates in a range from approximately 1000°C (1800°F) up to a maximum of 1800°C (3272°F). The specific range of any given furnace is determined by its model, heating elements, and the material of the process tube being used.

The maximum temperature rating is only one part of the story. The true capability of a tube furnace lies in the synergy between its heating elements, the physical limits of the process tube, and the precision of its control system.

What Defines a "High Temperature" Tube Furnace?

A high-temperature tube furnace is a specialized piece of equipment designed for thermal processing in a controlled environment. Understanding its core components clarifies its capabilities.

The Core Operating Principle

At its heart, a tube furnace is an electric heater built around a cylindrical cavity. Insulated heating elements, often coils, wrap around this central chamber. When electricity passes through them, they generate intense, uniform heat within the furnace.

The Critical Temperature Threshold

While lower-temperature models exist, the "high temperature" designation generally applies to furnaces capable of operating above 1000°C (1800°F). This range is necessary for applications like sintering ceramics, annealing metals, and advanced materials synthesis.

Maximum Operating Temperature

The upper limit for commercially available high-temperature tube furnaces is typically 1800°C. Reaching these temperatures requires specialized heating elements and high-purity ceramic components to withstand the extreme thermal stress.

Key Factors That Determine Performance

The advertised temperature range is a headline figure. True performance and suitability for your task depend on a few critical, interconnected factors.

The Engine: Heating Elements

The material of the heating elements dictates the furnace's maximum potential temperature. Common high-temperature elements are made from materials like silicon carbide (SiC) or molybdenum disilicide (MoSi2), each offering different performance characteristics and lifespans.

The Workhorse: The Process Tube

The sample being processed is held within a separate process tube, which is inserted through the furnace's heated chamber. The material of this tube—often quartz, alumina, or mullite—has its own maximum temperature rating, which can be lower than the furnace itself. This is often the true limiting factor for an experiment.

The Brain: Precision Control Systems

Simply reaching a high temperature is not enough; it must be stable and repeatable. This is achieved with an advanced PID (Proportional-Integral-Derivative) controller. This system constantly monitors the temperature via a thermocouple and makes precise adjustments to the power, ensuring the furnace holds the set temperature with minimal fluctuation.

The Goal: Uniformity Across the Heating Zone

The heating zone is the length of the furnace that maintains a stable, uniform temperature. These can range from under 300 mm to over 1200 mm. For processing larger samples or multiple small ones, a longer, more uniform heating zone is critical for consistent results. Multi-zone furnaces use separate controllers for different sections to achieve superior uniformity.

Understanding the Trade-offs

Choosing a furnace involves balancing competing priorities. Being aware of these trade-offs is key to avoiding costly mistakes.

Maximum Temperature vs. Tube Material

This is the most common pitfall. You may have an 1800°C furnace, but if you use a quartz tube (max temp ~1200°C), you are limited to the tube's rating. For higher temperatures, you must use a high-purity alumina tube, which is more expensive and brittle.

Ramp Rate vs. Component Longevity

A rapid ramp rate (how quickly the furnace heats up) is desirable for efficiency. However, aggressive heating and cooling cycles place significant thermal stress on both the heating elements and the process tube, potentially reducing their operational lifespan.

Single-Zone vs. Multi-Zone Control

A single-zone furnace is simpler and more cost-effective. However, a multi-zone furnace provides far superior temperature uniformity across the process tube, which is essential for sensitive applications. This advanced control comes with increased complexity and cost.

Making the Right Choice for Your Application

Selecting the right furnace requires looking beyond the maximum temperature and considering the entire system in the context of your goal.

- If your primary focus is reaching the absolute highest temperatures (above 1600°C): You must select a furnace with MoSi2 elements and pair it with a high-purity alumina process tube.

- If your primary focus is precise, repeatable processing: Prioritize a furnace with an advanced, programmable PID controller and consider a multi-zone model for superior temperature uniformity.

- If your primary focus is working with controlled atmospheres or vacuum: Ensure the furnace system and your chosen process tube are rated for those conditions and have the appropriate end seals and fittings.

Ultimately, the best furnace is the one whose entire system—heating, containment, and control—is perfectly matched to your specific processing requirements.

Summary Table:

| Factor | Key Details | Impact on Temperature Range |

|---|---|---|

| Heating Elements | Materials like SiC or MoSi2 | Dictate maximum temperature (up to 1800°C) |

| Process Tube | Materials like quartz or alumina | Can limit temperature (e.g., quartz max ~1200°C) |

| Control System | PID controllers | Ensures stable, repeatable temperatures |

| Heating Zone | Length and uniformity | Affects consistency across samples |

Need a high-temperature tube furnace tailored to your lab's unique needs? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your experimental requirements—whether you need high temperatures, precise control, or specialized atmospheres. Contact us today to discuss how we can enhance your thermal processing efficiency and results!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- How do vertical tube furnaces comply with environmental standards? A Guide to Clean, Efficient Operation