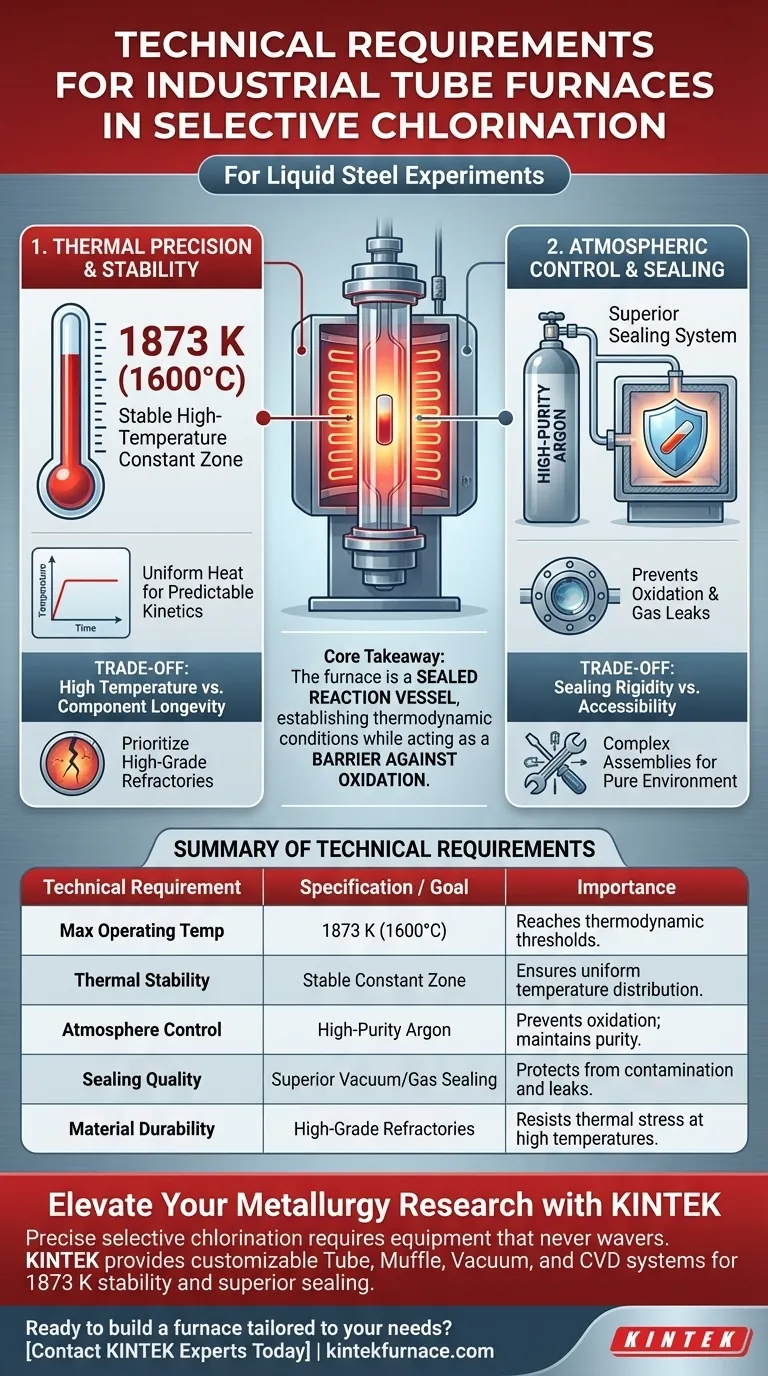

To ensure experimental validity in selective chlorination, the industrial tube furnace requires two specific technical capabilities: a stable high-temperature constant zone capable of reaching 1873 K, and a superior sealing system designed to maintain a high-purity argon protective atmosphere. These specifications are non-negotiable for facilitating the reaction between liquid steel and molten flux without atmospheric contamination.

Core Takeaway The furnace functions not merely as a heater, but as a sealed reaction vessel. Its primary role is to establish specific thermodynamic conditions while acting as a barrier against oxidation, ensuring that results are driven purely by the interaction between the steel and the flux.

Thermal Precision and Stability

Reaching Thermodynamic Thresholds

Selective chlorination experiments often require extreme heat to initiate and sustain the necessary chemical reactions. Your furnace must be capable of reaching and holding 1873 K (approximately 1600°C).

The Importance of the Constant Zone

It is not enough to simply reach peak temperature; the furnace must maintain a stable constant zone.

Fluctuations in temperature can alter the thermodynamic conditions. Precision here ensures that the reaction between the liquid steel and molten flux proceeds predictably.

Atmospheric Control and Sealing

The Role of High-Purity Argon

To protect the liquid metal, the furnace must accommodate a high-purity argon protective atmosphere.

At 1873 K, liquid steel is highly reactive to oxygen. Even trace amounts of air will cause immediate oxidation, compromising the data regarding the chlorination process.

Superior Sealing Performance

The physical integrity of the furnace is critical. You must utilize a unit with superior sealing performance to prevent the ingress of outside air and the leakage of the protective gas.

This sealing creates a controlled environment where the only variables are those you introduce: the steel, the flux, and the chlorination agents.

Understanding the Trade-offs

High Temperature vs. Component Longevity

Operating continuously at 1873 K places immense stress on furnace components, particularly the heating elements and the tube itself.

While high temperatures are required for the thermodynamic conditions of the reaction, they accelerate wear. You must prioritize high-grade refractory materials, even if they come at a higher initial cost.

Sealing Rigidity vs. Accessibility

Achieving "superior sealing" often requires complex flange assemblies or vacuum-tight fittings.

The trade-off is often ease of access. Loading samples and cleaning the tube becomes more time-consuming, but this is a necessary sacrifice to prevent oxidation interference.

Making the Right Choice for Your Goal

When selecting or configuring your furnace, prioritize the features that align with your specific experimental risks.

- If your primary focus is Thermodynamic Accuracy: Prioritize the length and stability of the constant heating zone to ensure uniform temperature distribution across the sample.

- If your primary focus is Sample Purity: Prioritize the integrity of the vacuum/sealing system and the quality of the argon gas flow regulation to eliminate oxidation.

Your equipment must provide a stable thermal baseline and a chemically inert environment to turn raw heat into reliable data.

Summary Table:

| Technical Requirement | Specification / Goal | Importance in Selective Chlorination |

|---|---|---|

| Max Operating Temp | 1873 K (1600°C) | Reaches necessary thermodynamic thresholds for liquid steel reactions. |

| Thermal Stability | Stable Constant Zone | Ensures uniform temperature distribution and predictable reaction kinetics. |

| Atmosphere Control | High-Purity Argon | Prevents liquid steel oxidation and maintains chemical purity. |

| Sealing Quality | Superior Vacuum/Gas Sealing | Protects the reaction vessel from atmospheric contamination and gas leaks. |

| Material Durability | High-Grade Refractories | Resists thermal stress and component wear at extreme high temperatures. |

Elevate Your Metallurgy Research with KINTEK

Precise selective chlorination requires equipment that never wavers under extreme heat. KINTEK provides high-performance Tube, Muffle, Vacuum, and CVD systems designed to meet the rigorous demands of liquid steel experimentation. Backed by expert R&D and world-class manufacturing, our furnaces are fully customizable to provide the 1873 K stability and superior sealing performance your data depends on.

Ready to build a furnace tailored to your unique research needs?

Visual Guide

References

- Hongyan Sun, Z. R. Chen. Copper Removal of Liquid Steel Containing 0.25% Carbon Using Fe<sub>2</sub>O<sub>3</sub>–CaCl<sub>2</sub>–SiO<sub>2</sub> Flux. DOI: 10.2355/isijinternational.isijint-2025-083

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What are the key components of a tube furnace's heating mechanism? Discover Precision Heating for Your Lab

- What safety precautions should be followed when operating a multi zone tube furnace? Ensure Safe and Efficient Lab Operations

- What are the primary industries that use split tube furnaces? Essential for High-Temp Material Processing

- How does a tube furnace facilitate the structural stabilization of lignin? Mastering Lignin-to-Carbon Transformation

- How does a laboratory tube furnace achieve controlled atmosphere sintering? Master Precision Catalytic Prep

- What is the purpose of introducing high-purity nitrogen into a tube furnace? Optimize Bone Pyrolysis & Biochar Yield

- What is the key component of a tube furnace and how is it constructed? Unlock Precision Heating for Your Lab

- What role does a tube furnace play in the one-step pyrolysis of Fe-BN-C catalysts? Precision Synthesis Explained