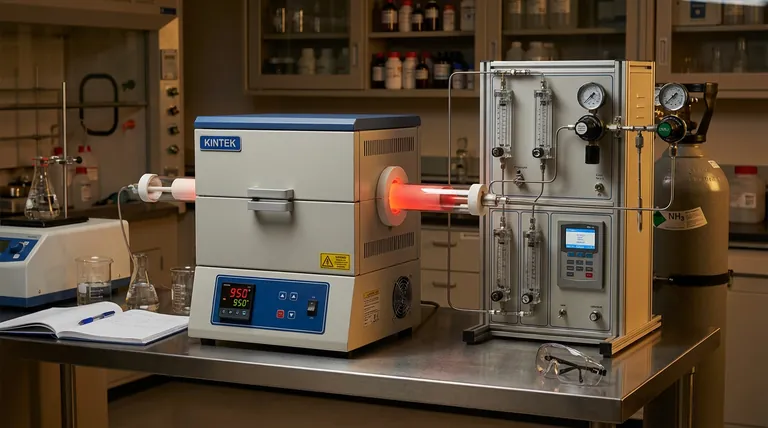

Converting oxides into Gallium Nitride (GaN) nanopowders requires a tube furnace equipped with an ammonia flow control system to maintain a stable reactive atmosphere at precisely 950°C. This specific setup enables the precise reduction and ammoniation necessary to chemically substitute oxygen atoms with nitrogen atoms within the material.

Core Takeaway: The synthesis of high-quality GaN is a chemical substitution process. It relies entirely on a stable, ammonia-rich environment at high heat to drive out oxygen and install nitrogen, a balance that is impossible to maintain without precise flow control.

Creating the Reactive Environment

The Role of Thermal Energy

To facilitate the conversion of oxides, the system must reach and maintain a temperature of 950 degrees Celsius.

At this thermal threshold, the stability of the oxide bonds is compromised. This high-energy state is strictly necessary to prepare the material for chemical change.

The Function of the Tube Furnace

The tube furnace acts as an isolation chamber. It allows the sample to be heated uniformly while completely separating it from the outside atmosphere.

This isolation is critical because the presence of uncontrolled atmospheric oxygen would inhibit the desired reaction.

The Mechanism of Ammoniation

Replacing Oxygen with Nitrogen

The core chemical process at work here is reduction and ammoniation.

As ammonia gas ($NH_3$) flows over the heated oxide powder, it decomposes and interacts with the particles.

The ammonia molecules effectively "attack" the oxide, facilitating a swap where oxygen atoms are removed and replaced by nitrogen atoms.

Achieving High Crystallinity

This process yields yellow Gallium Nitride (GaN) nanopowders.

The "high crystallinity" mentioned in technical specifications is a direct result of the thoroughness of this interaction. If the interaction is partial, the crystal structure will be defective.

Why Precision Matters (Risks of Instability)

The Necessity of Constant Flow

The reference emphasizes the need for a constant flow of ammonia.

A static atmosphere is insufficient because the reaction consumes ammonia and releases oxygen byproducts.

Fresh ammonia must be continuously introduced to drive the reaction forward to completion.

Ensuring a Stable Atmosphere

The flow control system prevents fluctuations in gas pressure and concentration.

Without this precision, the "reactive atmosphere" becomes unstable.

instability leads to uneven nitridation, resulting in a mix of unreacted oxides and poor-quality GaN rather than pure, high-crystallinity nanopowder.

Making the Right Choice for Your Goal

To ensure you synthesize the highest quality materials, consider the following based on your specific requirements:

- If your primary focus is Phase Purity: Ensure your flow control system is calibrated to prevent any drops in pressure, as even momentary lapses can leave unreacted oxygen in the lattice.

- If your primary focus is Crystal Quality: strict adherence to the 950°C temperature setpoint is vital; deviations can alter the morphology of the resulting yellow nanopowder.

The tube furnace and flow system are not just heating elements; they are the active regulators of the chemical substitution that creates GaN.

Summary Table:

| Feature | Requirement for GaN Synthesis | Impact on Final Nanopowder |

|---|---|---|

| Target Temperature | Precisely 950°C | Ensures thermal energy to break oxide bonds |

| Gas Atmosphere | Constant Ammonia ($NH_3$) Flow | Drives chemical substitution of Oxygen with Nitrogen |

| Equipment Type | Sealed Tube Furnace | Prevents atmospheric oxygen contamination |

| Flow Control | Stable, High-Precision Regulation | Achieves high crystallinity and phase purity |

Elevate Your Material Synthesis with KINTEK

Achieving the perfect chemical substitution for Gallium Nitride (GaN) nanopowders requires more than just heat; it requires absolute precision. KINTEK provides industry-leading Tube, Vacuum, and CVD systems designed to maintain the rigorous 950°C thresholds and stable reactive atmospheres your research demands.

Backed by expert R&D and advanced manufacturing, our high-temp furnaces are fully customizable to meet your unique gas flow and thermal processing needs. Ensure your lab produces high-crystallinity results every time.

Contact KINTEK Experts Today for a Custom Solution

References

- Laser induced white emission and photocurrent of GaN nanoceramics. DOI: 10.1038/s41598-025-14109-6

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Magnesium Extraction and Purification Condensing Tube Furnace

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- What is the specific role of a tube furnace in the synthesis and carbon-encapsulation of NiMo alloys? Explained

- Why is a high-precision dual-zone furnace required for 1T-TaS2 crystals? Achieve Perfect CVT Phase Integrity

- How does a tube vacuum furnace ensure quality during the solution treatment of aluminum matrix composites? Unlock Precision and Purity for Superior Materials

- How does a tube furnace contribute to the synthesis of electrocatalysts from hydrochar? Precision Thermal Engineering

- What safety features are included in tube furnaces? Essential Protection for High-Temperature Labs

- What are the functional advantages of utilizing a high-temperature vertical tube quartz reactor for MoS2/rGO pyrolysis?

- What role does a Tube Furnace play in HDS catalyst de-oiling? Unlock Efficient Pyrolysis Recovery

- How do temperature control and uniformity differ between vertical and horizontal tube furnaces? Optimize Your Lab's Heat Processing