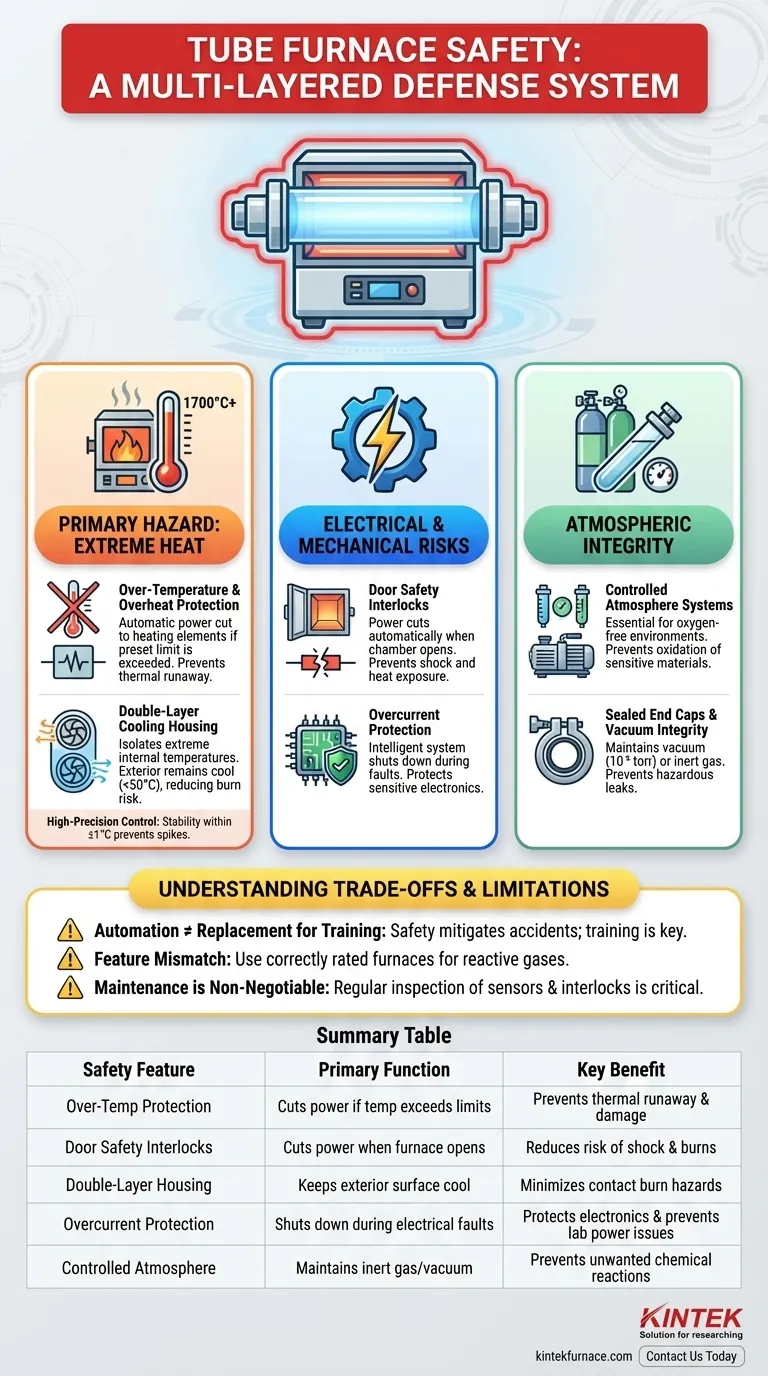

At their core, tube furnace safety features are a multi-layered defense system designed to protect against the primary operational hazards: extreme heat, high-voltage electricity, and controlled atmospheric conditions. Key safety mechanisms include automatic over-temperature protection to prevent thermal runaway, electrical interlocks that cut power when the furnace is opened, and double-layer housing that keeps the exterior surface cool and safe to touch.

A tube furnace's safety is not a single feature but an integrated system. It is engineered to proactively manage and automatically contain the inherent risks of high-temperature processing, protecting the user, the experiment, and the equipment from failure.

Protecting Against the Primary Hazard: Extreme Heat

The most obvious danger of a tube furnace is its ability to generate temperatures exceeding 1700°C. Modern safety features are designed to both contain this heat and act as a failsafe against control system failure.

Over-Temperature and Overheat Protection

This is your most critical thermal failsafe. A dedicated sensor and controller, separate from the main temperature regulator, monitors the furnace chamber.

If the primary controller malfunctions and the temperature rises beyond a preset safety limit, this secondary system will automatically cut all power to the heating elements. This prevents catastrophic overheating that could destroy the furnace, your sample, and create a fire hazard.

Double-Layer Cooling Housing

You should never have to guess if a furnace is dangerously hot from the outside. Modern furnaces use a double housing design, often with a fan-cooled air gap between the inner and outer shells.

This design effectively isolates the extreme internal temperatures. It ensures the exterior surface remains at a low temperature, often below 50°C (and sometimes as low as 30°C), even when the furnace is operating at 800°C or higher. This drastically reduces the risk of severe contact burns.

Precise Temperature Control

While seen as an operational feature, high-precision temperature control is also a proactive safety measure. Controllers with programmable segments and stability within ±1°C prevent unexpected temperature spikes.

This stability protects the integrity of your experiment and prevents thermal stress on the furnace tube and heating elements, which could otherwise lead to premature failure.

Managing Electrical and Mechanical Risks

Beyond heat, a tube furnace is a high-power electrical device. Safeguards are built in to protect operators from electrical shock and the equipment from power anomalies.

Door Safety Interlocks

This is a simple but essential mechanical safety feature. An interlock switch automatically cuts power to the heating elements the moment the furnace chamber door or sliding cover is opened.

This crucial feature prevents user exposure to both live electrical components and the intense radiant heat of the furnace interior, mitigating risks of both electrical shock and severe burns.

Overcurrent Protection

Think of this as an intelligent, built-in circuit breaker. The furnace's power system is monitored for electrical shorts or power surges.

If an overcurrent condition is detected, the system immediately shuts down. This protects the furnace’s sensitive and expensive electronic components and prevents a fault from tripping breakers for the entire lab.

Ensuring Atmospheric Integrity

Many processes require a vacuum or a specific inert gas atmosphere. These systems have safety implications for preventing unwanted and potentially hazardous chemical reactions.

Controlled Atmosphere Systems

Features like vacuum systems and gas flow controllers are essential for working in an oxygen-free environment. This is critical for preventing the high-temperature oxidation of sensitive materials.

By ensuring a pure, controlled atmosphere of argon or nitrogen, the system prevents unwanted chemical reactions that could otherwise ruin the sample or, in rare cases, create a hazard.

Sealed End Caps and Vacuum Integrity

The end caps that seal the process tube are critical for safety and process reliability. High-quality seals are necessary to maintain a vacuum (down to 10^-5 torr) or to prevent inert gas from leaking out and ambient air from leaking in.

A compromised seal can lead to a sudden loss of the protective atmosphere, exposing a hot, reactive material to oxygen and causing immediate, irreversible damage.

Understanding the Trade-offs and Limitations

Automated safety features are powerful but are not a substitute for proper procedure and awareness. Understanding their limits is key to a truly safe operation.

Automation is Not a Replacement for Training

Safety features are designed to mitigate the consequences of an accident or failure; they are not a replacement for proper training and adherence to standard operating procedures. A user who is unaware of the potential hazards is a risk, no matter how advanced the equipment.

Feature and Application Mismatch

A furnace rated for an inert gas atmosphere is not inherently safe for use with reactive or flammable gases. Using a furnace for a process it was not designed for can bypass its built-in safety features and create a significant, uncontrolled hazard.

Maintenance is Non-Negotiable

Sensors, interlocks, and seals can fail over time. A safety interlock that has been bypassed or a temperature sensor that has failed is worse than having no feature at all, as it creates a false sense of security. Regular inspection and maintenance are critical.

Making the Right Choice for Your Goal

When selecting or operating a furnace, match its safety profile to your specific application.

- If your primary focus is general lab use with stable materials: Prioritize furnaces with robust over-temperature protection, a cool-touch double housing, and clear door interlocks.

- If your primary focus is working with controlled atmospheres: Ensure the furnace has an integrated and reliable vacuum system, high-quality sealed end caps, and precise gas flow controls.

- If your primary focus is unattended or long-duration processes: Look for advanced programmable controllers with remote monitoring, data logging, and comprehensive automated alerts for any system deviation.

Understanding how these safety systems work in unison is the foundation for performing safe, reliable, and successful high-temperature work.

Summary Table:

| Safety Feature | Primary Function | Key Benefit |

|---|---|---|

| Over-Temperature Protection | Automatically cuts power if temperature exceeds limits | Prevents thermal runaway and equipment damage |

| Door Safety Interlocks | Cuts power when furnace is opened | Reduces risk of electrical shock and burns |

| Double-Layer Cooling Housing | Keeps exterior surface cool | Minimizes contact burn hazards |

| Overcurrent Protection | Shuts down during electrical faults | Protects electronics and prevents lab-wide power issues |

| Controlled Atmosphere Systems | Maintains inert gas or vacuum environments | Prevents unwanted chemical reactions and sample damage |

Ensure your lab's safety and efficiency with KINTEK's advanced high-temperature furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we offer Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all with strong deep customization to meet your unique experimental needs. Contact us today to discuss how our tailored solutions can protect your processes and enhance performance!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- How is a Vertical Tube Furnace used for fuel dust ignition studies? Model Industrial Combustion with Precision

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety